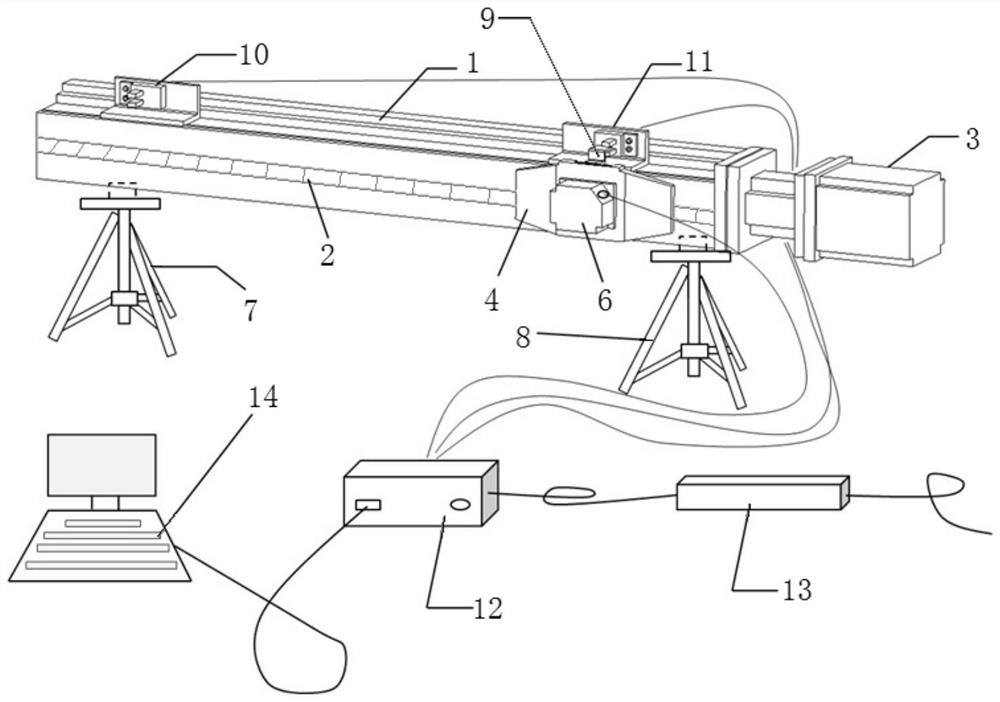

Portable surface defect detection device and method based on laser displacement ranging

A laser displacement and defect detection technology, applied in the field of laser measurement, can solve problems such as inability to realize on-site application, lack of workpiece defect detection ability, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The following x-direction, y-direction, and z-direction correspond to the x-axis, y-axis, and z-axis of the space Cartesian coordinate system. When detecting the depth of workpiece surface defects, first fix the left and right support frames and adjust the level of the body so that Keep the body level, place the workpiece between the left and right support frames, adjust the height of the support frame with reference to the measured workpiece, place the measured workpiece in the measurement range of the laser displacement sensor, and the laser displacement sensor faces the workpiece to measure the vertical Z of the workpiece surface Displacement in the direction; zero calibration of the laser displacement sensor, determine the reference plane of the workpiece surface, and connect the host computer through the hub, such as a laptop; open the data acquisition software in turn, control the button, drive the ball screw to carry out the horizontal x direction of the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com