Method for preprocessing vibration signal of mechanical component with missing value

A vibration signal and mechanical component technology, which is applied in the field of mechanical component vibration signal preprocessing, can solve the problems of reduced reliability of mechanical component fault feature extraction results, lack of mechanical component vibration signals, and extraction of mechanical components, so as to ensure integrity and Authenticity, low computational requirements, and scientific evaluation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

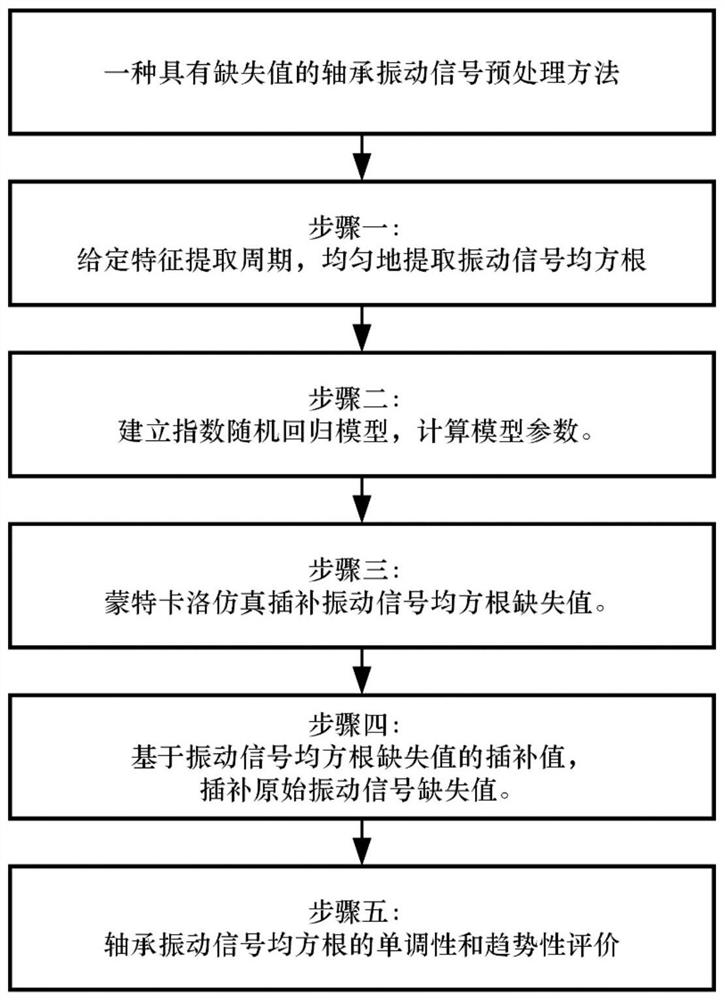

Method used

Image

Examples

Embodiment Construction

[0085] The present invention will be explained in detail below in combination with actual cases.

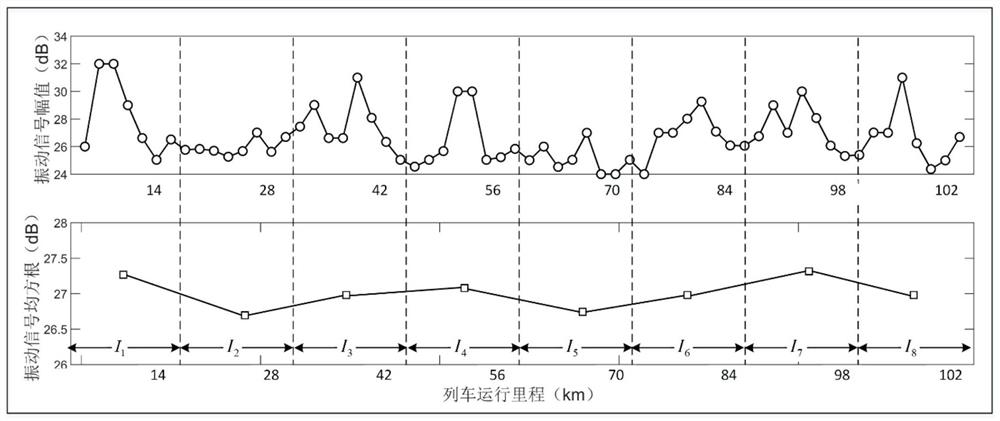

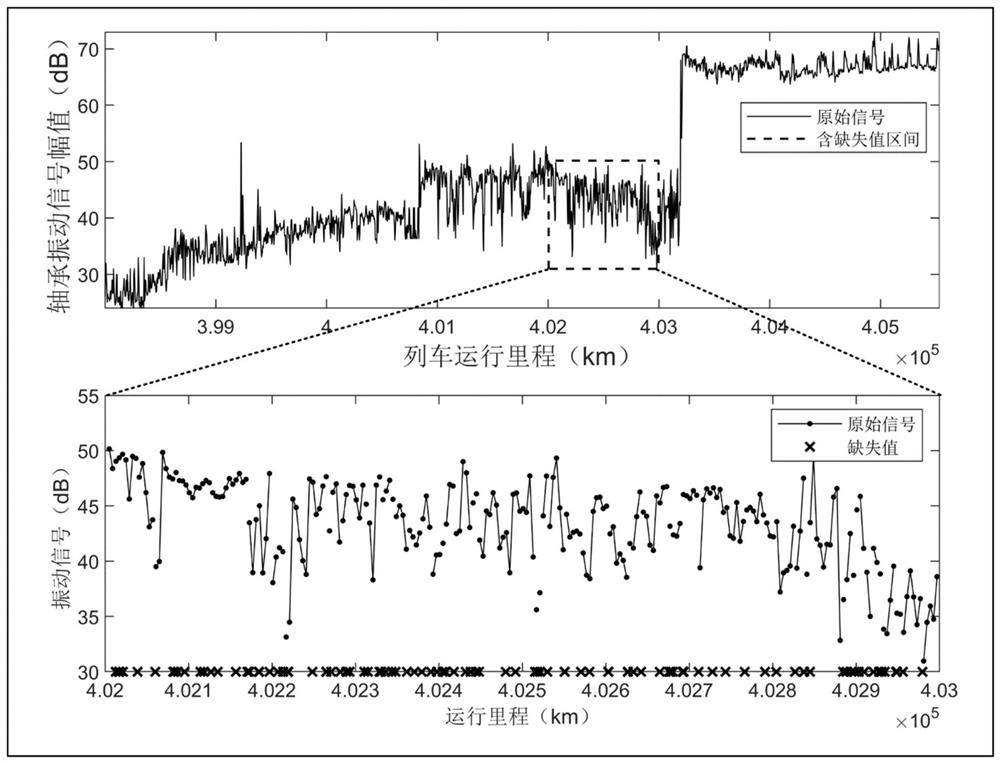

[0086] The axlebox bearing of a certain vehicle is subjected to external vibration shock during the working process, which affects the operation safety. In order to monitor its health status in real time, a constant period continuous sampling method is used to monitor the vehicle mileage and the original vibration amplitude of the bearing. The sampling period is 4km, that is, every 4km Record data once. In the process of bearing vibration signal collection, there is no data missing in the vehicle’s running mileage, and the mileage coverage is as high as 7540km. However, due to equipment replacement and communication failure, there are 100 missing values in the original vibration amplitude of the bearing, which leads to the inability to accurately and reasonably derive from the original data. Mining and extraction of bearing health status degradation information. The original v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com