Quality pre-auditing method for cold rolling raw material warehouse

A raw material library, nuclear method technology, applied in the direction of resources, instruments, manufacturing computing systems, etc., can solve the problems of real-time, low accuracy, a lot of manpower, material resources and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

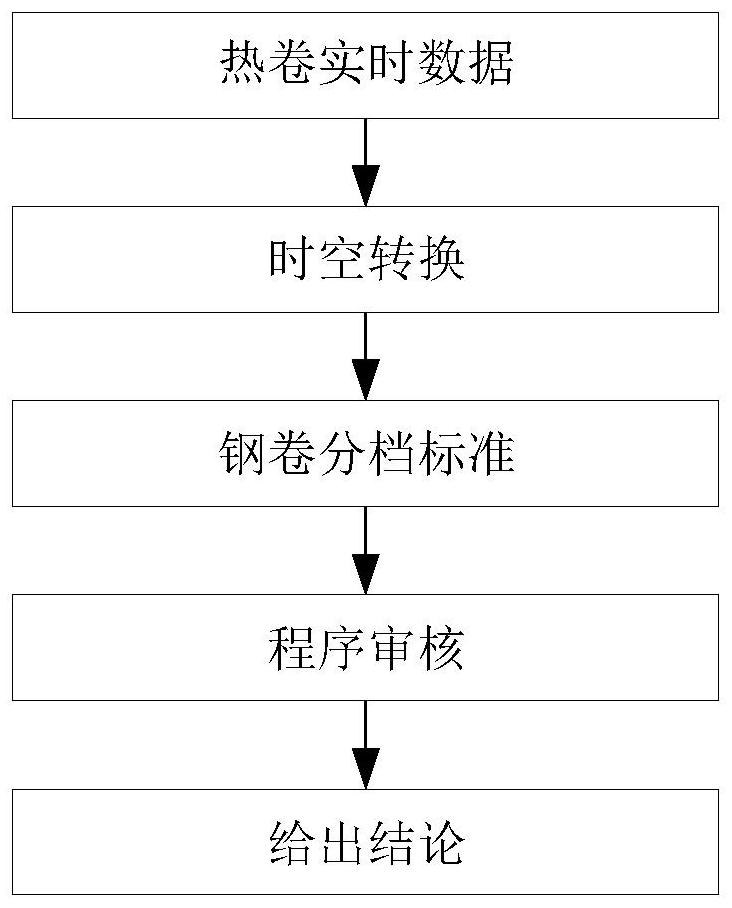

AI Technical Summary

Problems solved by technology

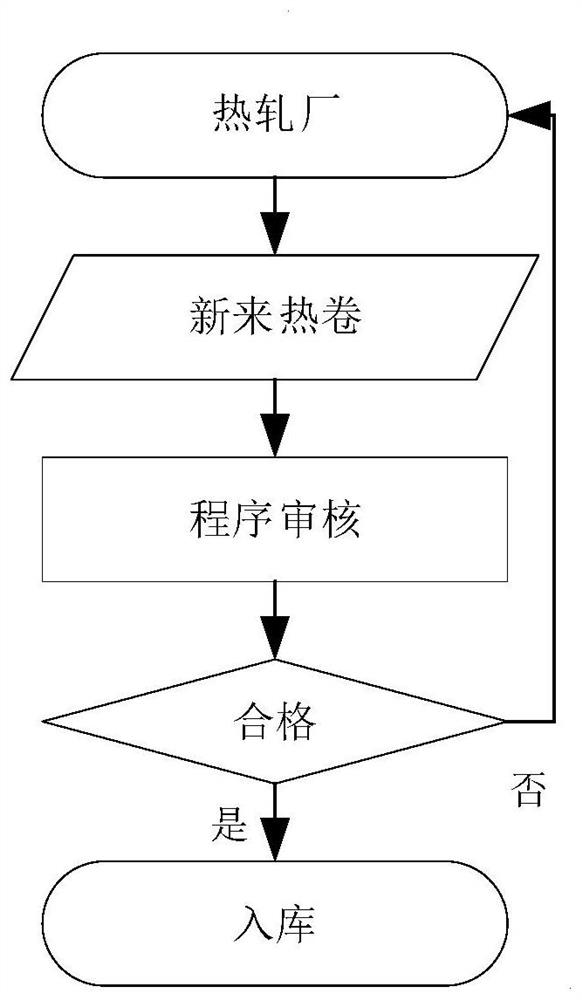

Method used

Image

Examples

Embodiment 1

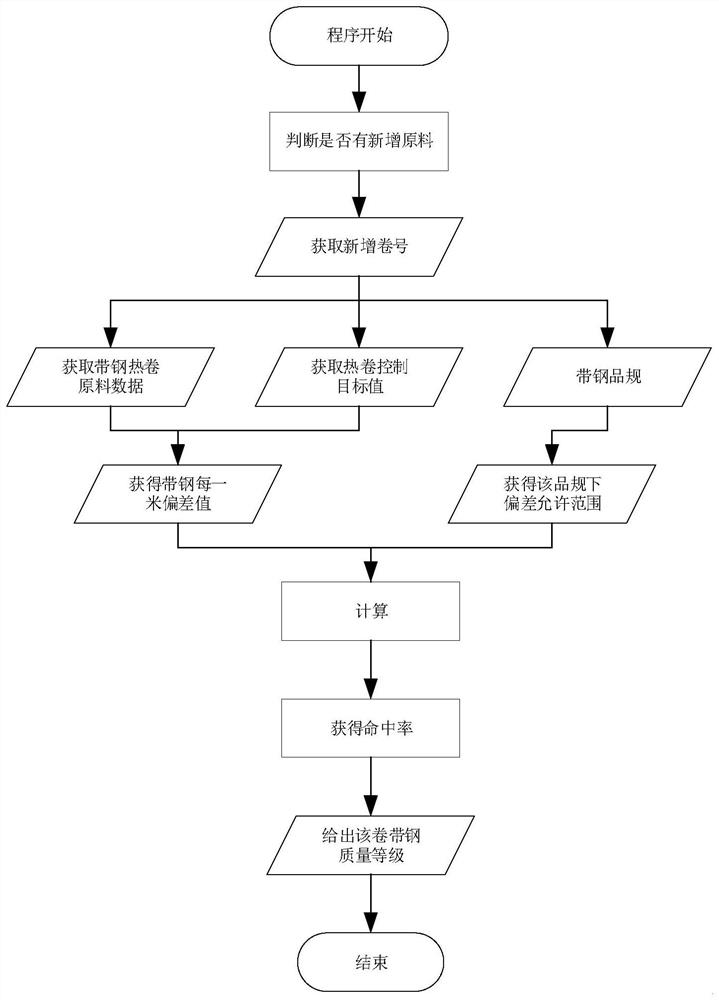

[0065] In the 2150 cold rolling production line of a domestic steel plant, a new batch of strip steel is added to the raw material warehouse, and the model checks the strip steel with the coil number J503H08080 in this batch. The above-mentioned roll number entrance thickness is 3.25mm, width is 1350mm, and a roll of strip steel with steel grade S2, such as figure 2 , image 3 Shown:

[0066] 1): When the hot coil number J503H08080 is in hot rolling production, the target width of the hot coil of this coil is 1350, and the actual measured value is compared with the target value to obtain the deviation value. According to the time-space transformation, the real-time production process parameters are transformed through time and space to obtain The data of each meter of each parameter of the strip steel in this coil is stored in the database.

[0067] 2): Classify the strip steel:

[0068] The specification of this strip steel is as follows: the thickness is 3.25mm, the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com