Fluid-assembled micron-sized device module and manufacturing method thereof

A micron-scale, device technology, applied in the semiconductor field, can solve problems such as falling, easy rollover of functional chips, and unfavorable assembly implementation, and achieve the effect of reducing costs and low-cost solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] This embodiment provides a micron-scale device module for fluid assembly and a corresponding manufacturing method, wherein the functions of the micron-scale functional chips included in each micron-scale device are the same.

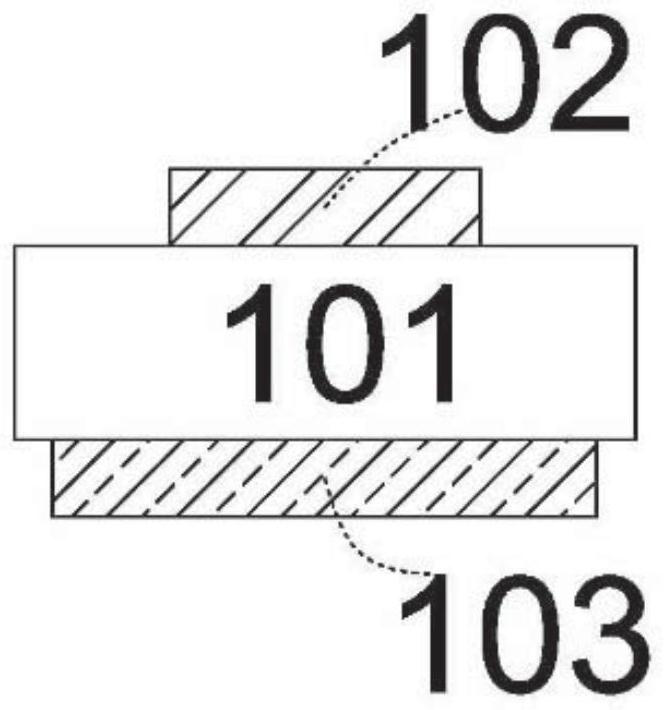

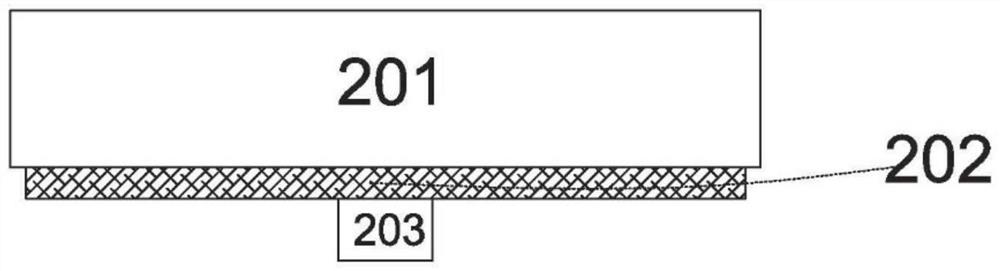

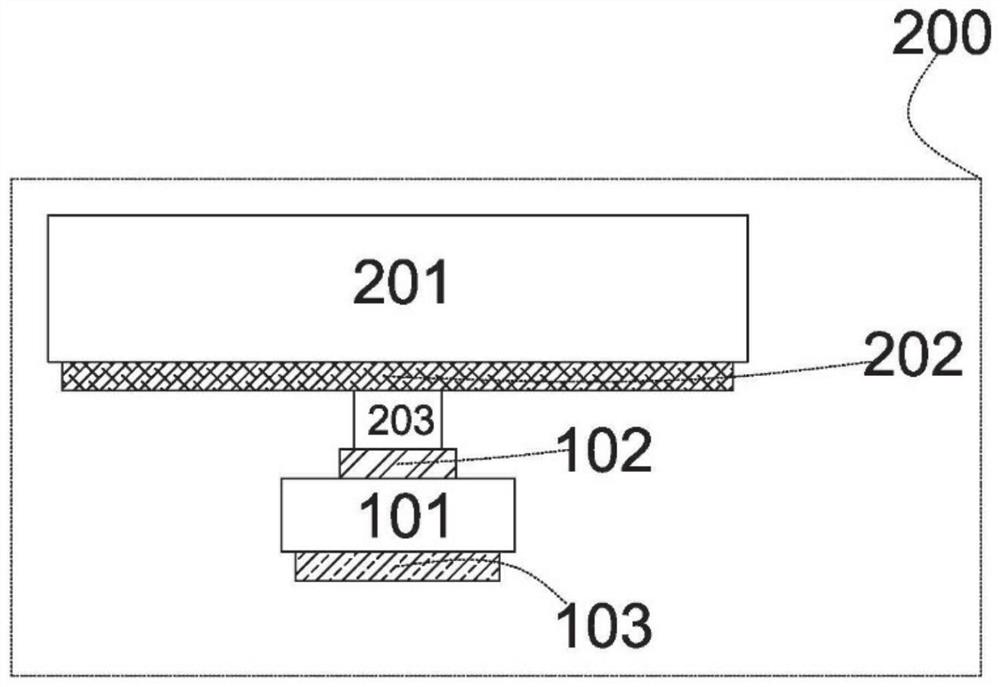

[0101] see Figure 1a-Figure 1e , Figure 1a-Figure 1e A schematic diagram of the components and the overall structure of a fluid-assembled micron-scale device module provided in Embodiment 1 is shown, wherein Figure 1a It is a schematic cross-sectional structure diagram of a micron-level functional chip, the micron-level functional chip is a vertical structure chip, and the micron-level functional chip has a first electrode 102 and a second electrode 103; Figure 1b is the cross-sectional structure of the intermediary substrate, the intermediary substrate has a conductive layer 202 and a soldering layer 203; Figure 1c Shows the structure of a micron-scale device 200 composed of a micron-scale functional chip and an intermediary substrate; F...

Embodiment 2

[0134] This embodiment provides a micron-level device module for fluid assembly and the corresponding manufacturing process. The functions of the micron-level function chips contained in each micron-level device are different. Typically, there are three micron-level devices with different functions. function chip.

[0135] see Figure 4a , which is a structural schematic diagram of a support substrate in a fluid-assembled micron-scale device module provided in this embodiment. The support substrate is 300, and the main body of the support substrate is provided with a first installation groove 311, a second installation groove 321, The third installation slot 331 is an installation slot with three structures and sizes.

[0136] Figure 4b It is a schematic structural diagram of a fluid-assembled micron-scale device module provided in this embodiment. The fluid-assembled micron-scale device module includes a first micron-scale functional chip 110, a first intermediary substrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com