A lithium metal negative electrode and its preparation and application

A lithium metal negative electrode, lithium metal technology, applied in the direction of negative electrodes, battery electrodes, lithium batteries, etc., can solve the problems of reducing the coulombic efficiency and cycle life of lithium metal batteries, low room temperature ion conductivity, and reducing ion conductivity, etc., to achieve Promotes uniform nucleation, improves electrical conductivity, and improves deposition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Glass plates are placed on both sides of the lithium sheet to form a laminated structure, and a polyethylene film (thickness 25 μm) is placed between the lithium sheet and the glass plate, and then the lithium sheet is pressed on the side of the glass plate away from the lithium sheet , the pressure is 0.2MPa, and the time is 20s; the lithium sheet with a diameter of 1.6mm and a thickness of 700μm is extruded with a glass plate padded with a polyethylene film to obtain a bright lithium sheet PLi (PLi means the extruded lithium sheet); Soak in tetrabutyl titanate for ex-situ reaction for 10 s, take out PLi and wipe off the tetrabutyl titanate liquid on the lithium surface with a non-woven fabric, dry for 15 min, and obtain an oxide layer (titanium oxide) with a thickness of about 500 nm. Lithium metal anode. A symmetrical battery was assembled using the treated lithium sheet as the electrode, celgard2325 as the separator, 1M lithium bis(trifluoromethylsulfonyl)imide (LiT...

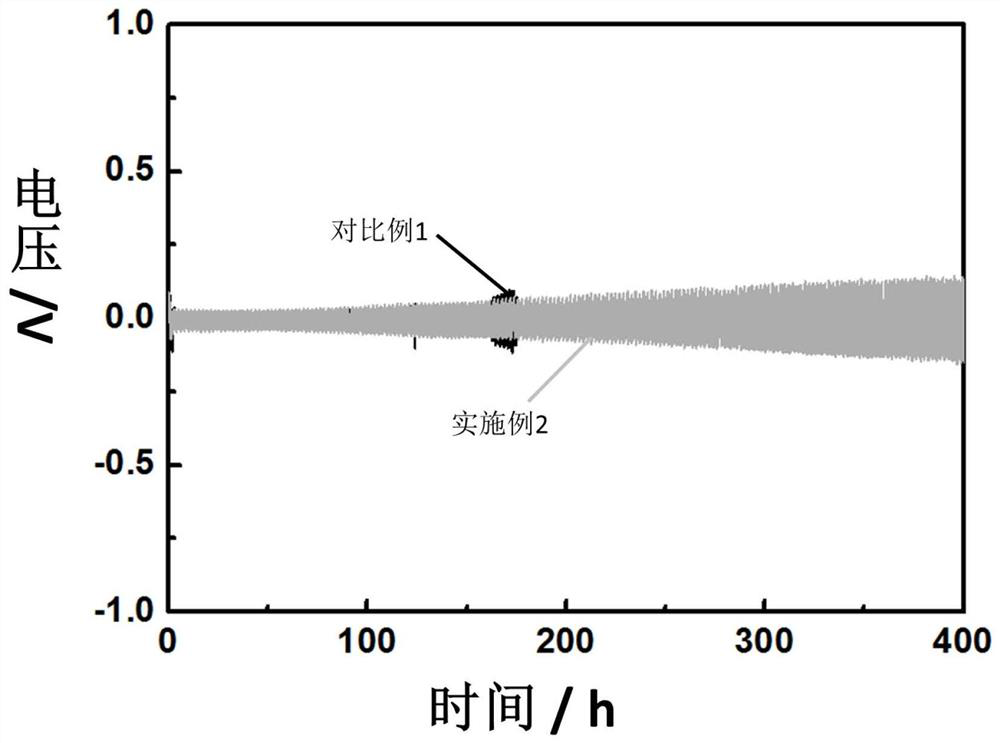

Embodiment 2

[0033] According to the process of Example 1, a glass plate with a diameter of 1.6 mm and a thickness of 700 μm was used to extrude a lithium sheet with a thickness of 700 μm to obtain a bright lithium sheet PLi; the PLi was immersed in tetrabutyl titanate for ex-situ reaction After 1 min, the PLi was taken out and the tetrabutyl titanate liquid on the lithium surface was wiped off with a non-woven fabric, and dried for 15 min to obtain a lithium metal negative electrode with an oxide layer (titanium oxide) with a thickness of about 800 nm. A symmetric battery was assembled using the treated lithium sheet as an electrode, and a lithium|lithium symmetric battery was assembled according to the method and conditions of Example 1. 1mA / cm 2 at a current density of 1mAh / cm 2 The deposition-dissolving capacity was carried out for charge-discharge cycles.

Embodiment 3

[0035] According to the process of Example 1, a glass plate with a diameter of 1.6 mm and a thickness of 700 μm was used to extrude a lithium sheet with a thickness of 700 μm to obtain a bright lithium sheet PLi; the PLi was immersed in tetrabutyl titanate for ex-situ reaction After 5 minutes, the PLi was taken out and the tetrabutyl titanate liquid on the lithium surface was wiped off with a non-woven fabric, and dried for 15 minutes to obtain a lithium metal negative electrode with an oxide layer (titanium oxide) with a thickness of about 1 μm. A symmetric battery was assembled using the treated lithium sheet as an electrode, and a lithium|lithium symmetric battery was assembled according to the method and conditions of Example 1. 1mA / cm 2 at a current density of 1mAh / cm 2 The deposition-dissolving capacity was carried out for charge-discharge cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com