Mine ecological restoration method applying mycorrhiza technology

A technology that uses mycorrhizae and ecological restoration, applied in the field of mine restoration, can solve the problems of slow overall soil restoration and ecological restoration in mines, and achieve the effects of avoiding groundwater pollution, reducing mobility and bioavailability, and enhancing survival and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

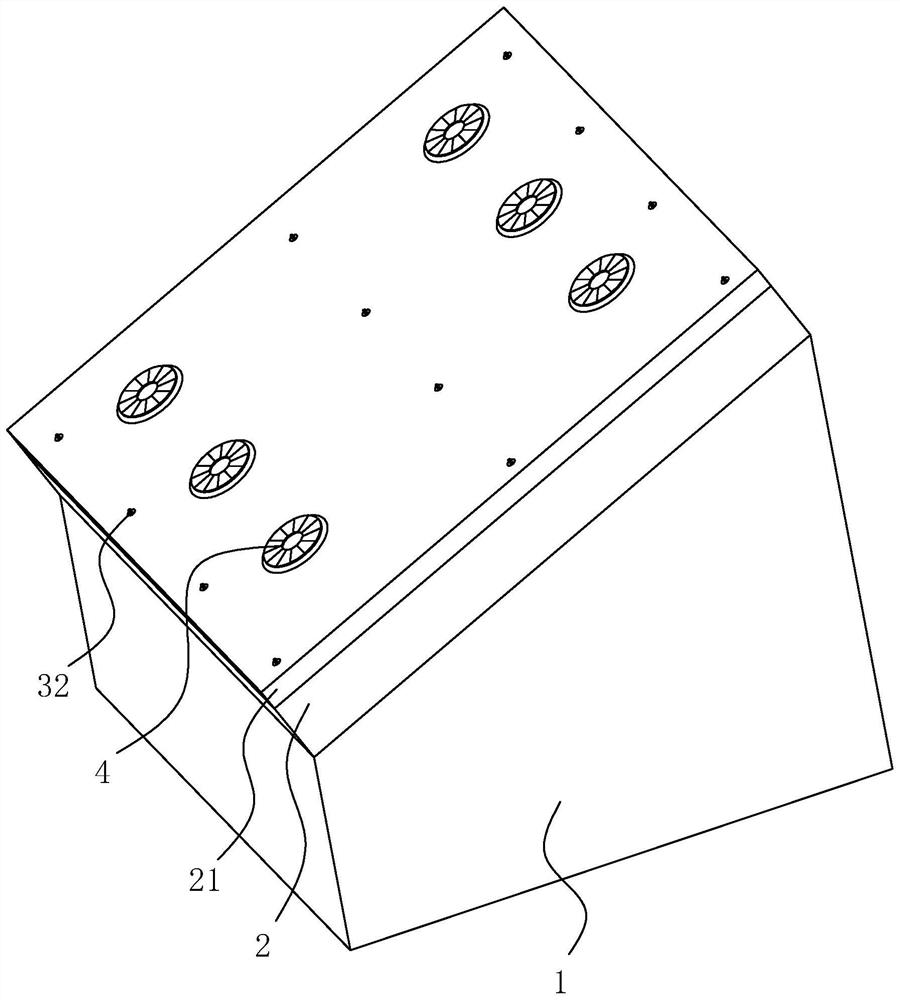

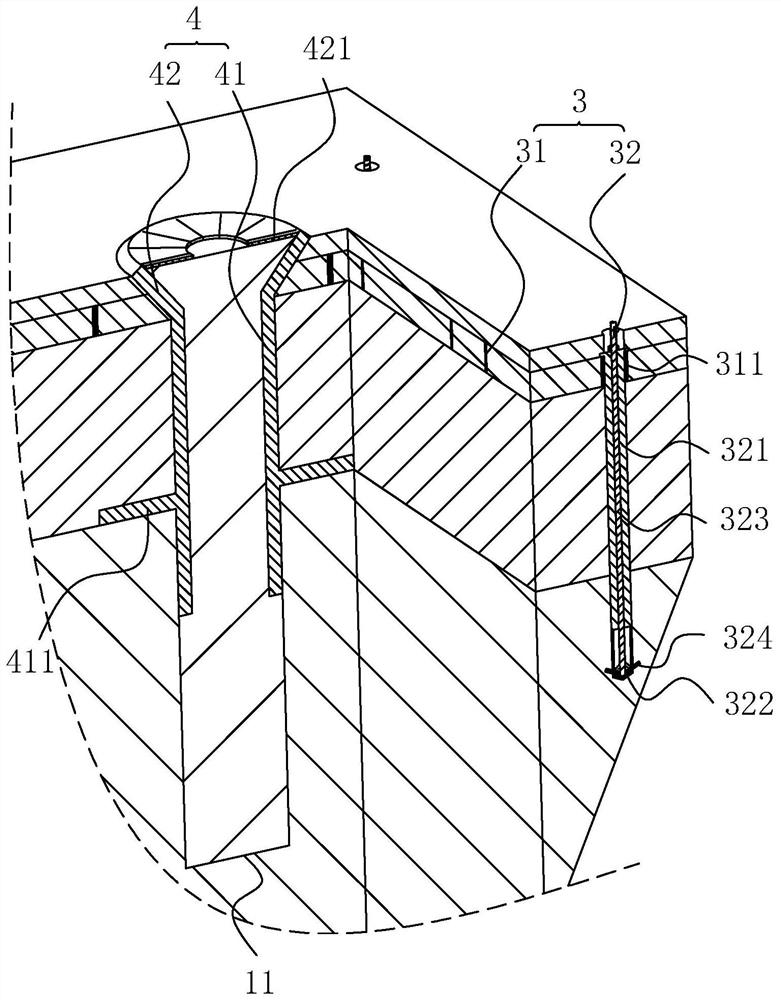

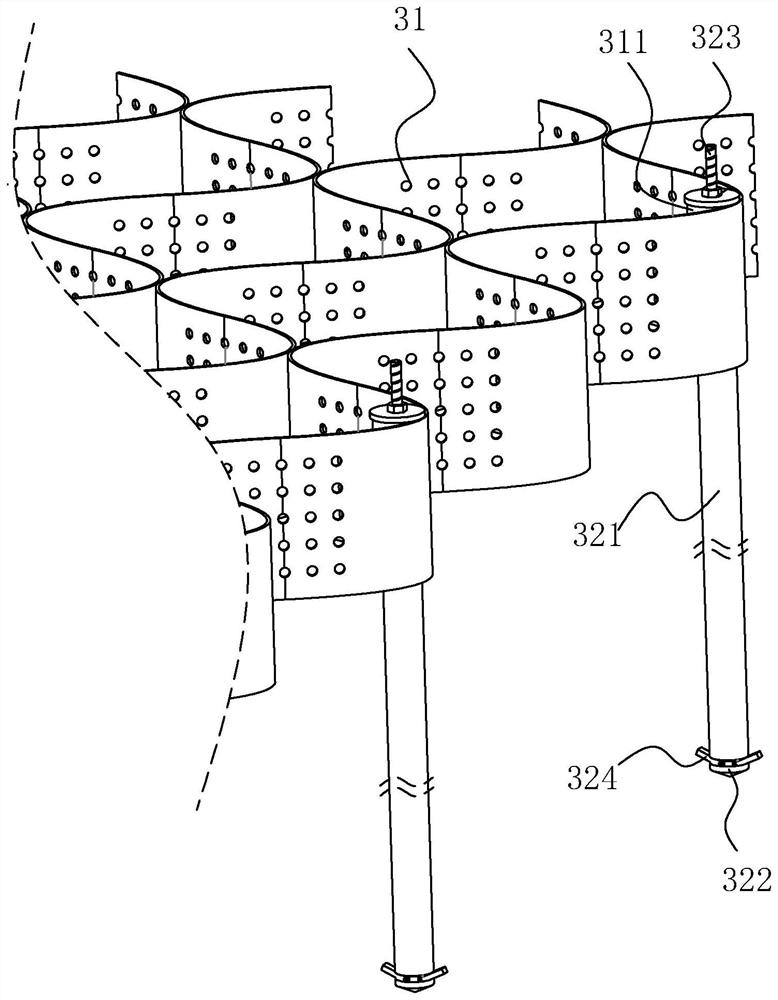

[0050] A mine ecological restoration method using mycorrhizal technology, comprising the following steps:

[0051] S1: Flatten the surface of the mine body, drill ecological holes downward at intervals, and the depth of the ecological holes is 4m;

[0052] S2: Lay the improved matrix in the ecological hole and on the surface of the mine to form a matrix layer. The thickness of the matrix layer is 5cm. The improved matrix includes the following components: 128kg of edible fungus chaff, 20kg of humus, 585kg of soil, 12kg of feather adsorbent, and Mud 25kg, mycorrhizal preparation 1.5kg, humus is peat;

[0053] Wherein, the feather adsorbent includes an alkali-treated adsorbent and a combined adsorbent with a weight ratio of 1:0.2, which are obtained by the following steps,

[0054] A1: Feathers are freeze-dried and pulverized with liquid nitrogen to a particle size of 0.1-0.6 mm;

[0055] A2: Soak the pulverized feathers in 0.1mol / L sodium hydroxide aqueous solution for 1.5h, ...

Embodiment 2

[0063] The difference with embodiment 1 is:

[0064] A mine ecological restoration method using mycorrhizal technology, comprising the following steps:

[0065] S1: Flatten the surface of the mine body, drill ecological holes downward at intervals, and the depth of the ecological holes is 4-10m;

[0066] S2: Lay the improved matrix in the ecological hole and on the surface of the mine to form a matrix layer. The thickness of the matrix layer is 5-15cm. The improved matrix includes the following components: edible fungus chaff 12-18kg, humus 15-20kg, soil 585- 630kg, feather adsorbent 8-12kg, sludge 25-32kg, mycorrhizal preparation 0.7-1.5kg, humus is peat and lignite with a mass ratio of 1:1;

[0067] Wherein, the feather sorbent includes an alkali-treated sorbent and a combined sorbent with a weight ratio of 1: (0.2-0.4), which is obtained by the following steps,

[0068] A1: Feathers are freeze-dried and pulverized with liquid nitrogen to a particle size of 0.1-0.6 mm;

...

Embodiment 3

[0072] The difference with embodiment 1 is:

[0073] A mine ecological restoration method using mycorrhizal technology, comprising the following steps:

[0074] S1: Level the surface of the mine body, drill ecological holes downward at intervals, and the depth of the ecological holes is 10m;

[0075] S2: Lay the improved substrate in the ecological hole and on the surface of the mine to form a substrate layer. Mud 32kg, mycorrhizal preparation 0.7kg, humus is peat, lignite, weathered coal with a mass ratio of 1:1:1;

[0076] Wherein, the feather sorbent includes an alkali-treated sorbent and a combined sorbent with a weight ratio of 1: (0.2-0.4), which is obtained by the following steps,

[0077] A1: Feathers are freeze-dried and pulverized with liquid nitrogen to a particle size of 0.1-0.6mm;

[0078] A2: Soak the crushed feathers in 0.1-0.5mol / L sodium hydroxide aqueous solution for 1.5-3h, filter, wash and dry to obtain the alkali-treated adsorbent;

[0079] A2: Add the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com