Corrosion reaction box for flow corrosion aluminum alloy casting complex slender copper pipe core

An aluminum alloy casting, flow corrosion technology, applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of long corrosion processing time, damage to aluminum alloy body, damage to aluminum alloy castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

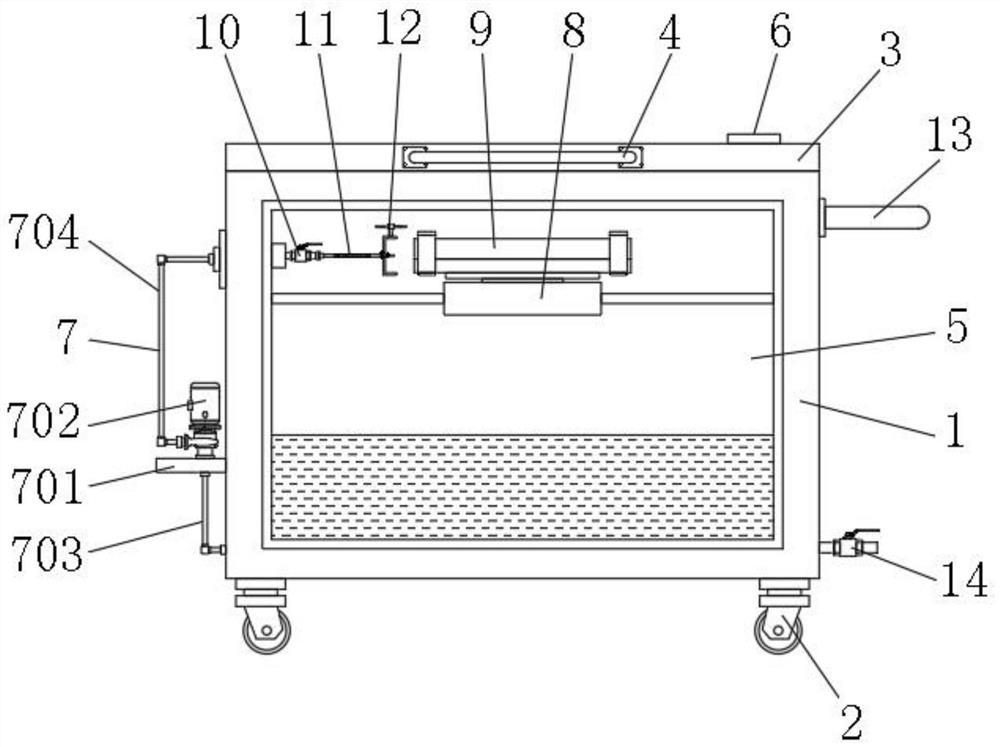

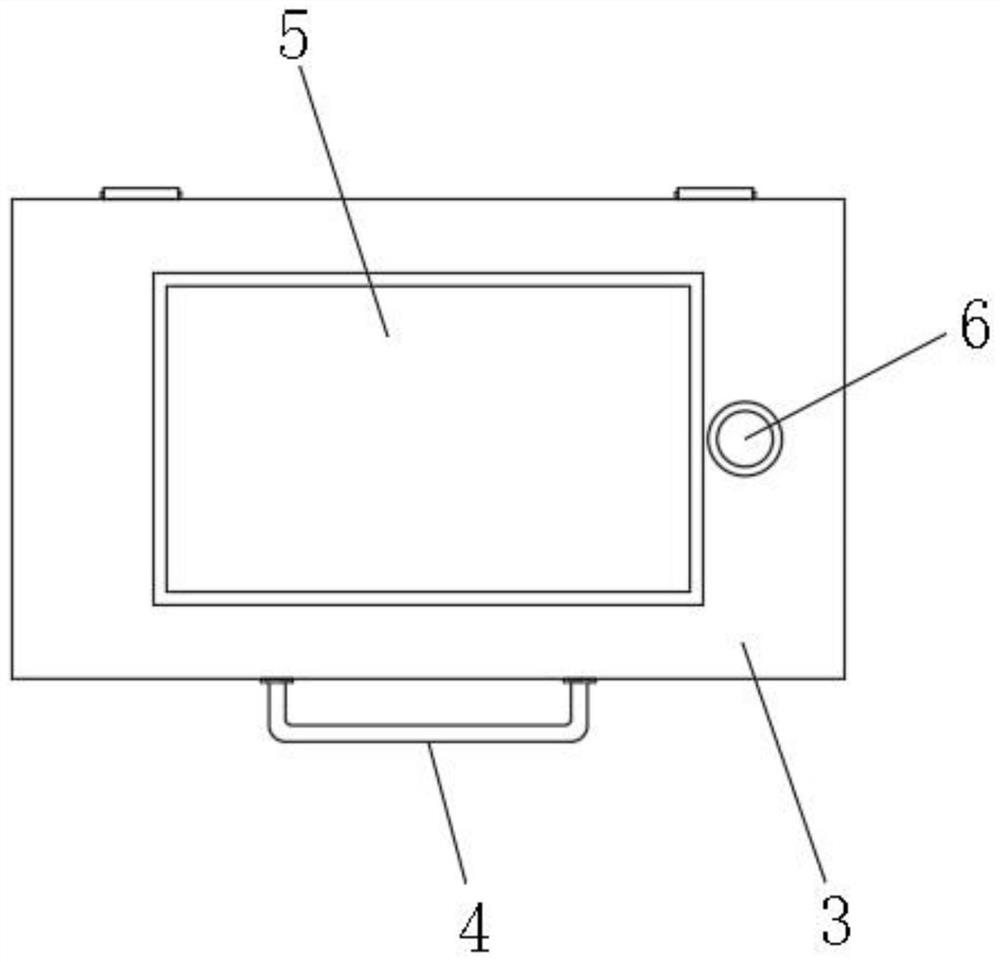

[0033] Such as Figure 1-6 As shown, the embodiment of the present invention provides a corrosion reaction box for flow corrosion of aluminum alloy castings complex and slender copper tube cores, including a box body 1, and universal wheels 2 are fixedly connected to the corners of the bottom of the box body 1, and the box body The top of the body 1 is rotatably connected with a sealed box cover 3, and the center of the front end of the sealed box cover 3 is fixedly connected with an unpacking handle 4, and the center of the front end of the box body 1 and the center of the top of the sealed box cover 3 are fitted with an observation window 5. One side of the top of the box cover 3 is provided with an exhaust port 6, and a certain amount of smoke will be generated after the chemical reaction between the corrosive liquid and the copper pipe. The generated flue gas is quickly extracted and processed centrally to prevent air pollution;

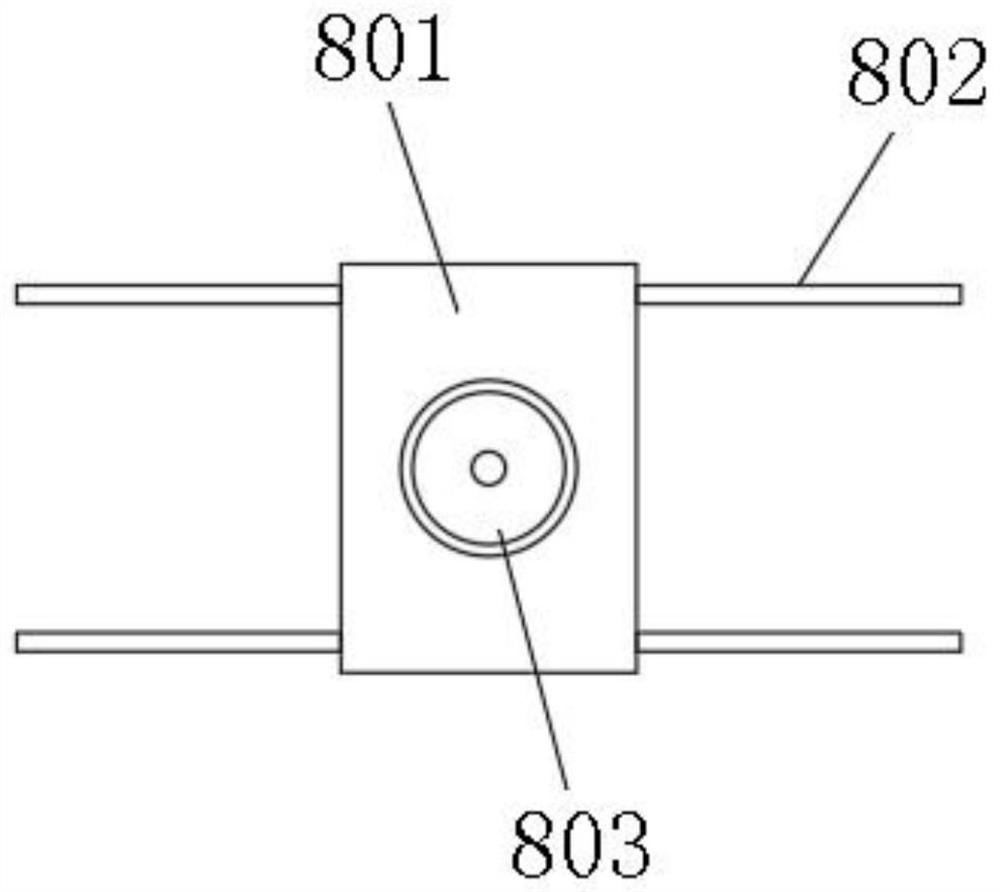

[0034] A corrosive liquid circulation mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com