Self-adaptive welding machine characteristic control circuit

An adaptive control and control circuit technology, applied in manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problems of inconvenient use, poor operation effect, and affecting the reliability of inverter power devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

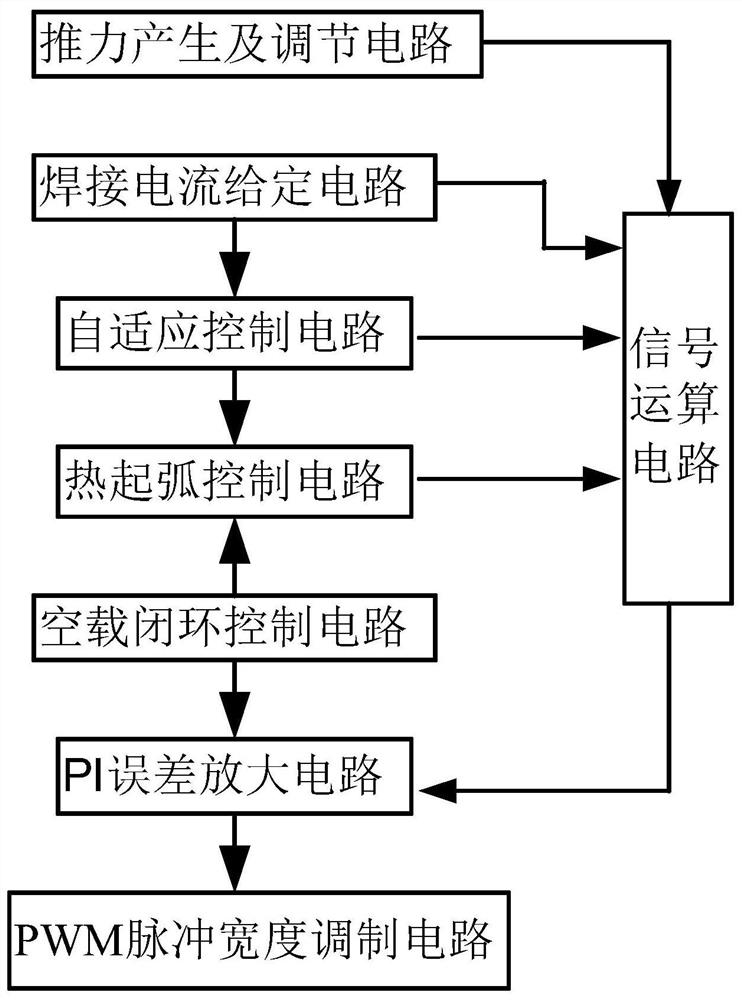

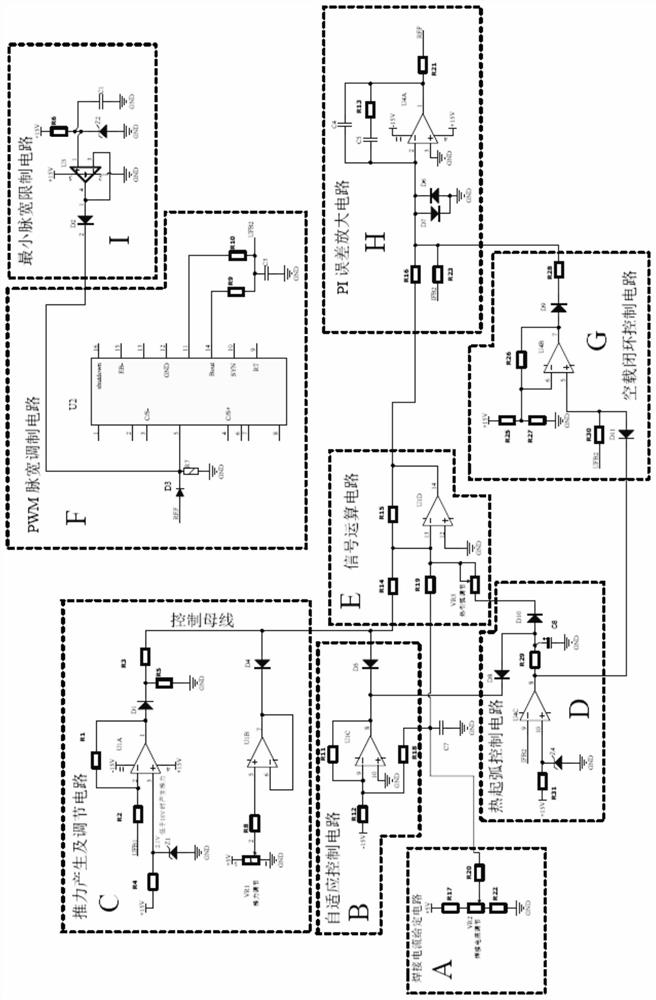

[0031] An adaptive welding machine characteristic control circuit of the present application, such as figure 1 As shown, it includes: welding current given circuit, thrust generation and adjustment circuit, thermal arc control circuit, adaptive control circuit, signal operation circuit, PWM pulse width modulation circuit.

[0032] The output of the welding current setting circuit, the output of the thrust generation and adjustment circuit, the output of the thermal arc control circuit, and the output of the adaptive control circuit are connected to the input of the signal operation circuit. The control signal and the thermal arc control signal are summed and inverted, and the calculation result is output.

[0033] One output of the adaptive control circuit and the output of the thrust generating and adjusting circuit are connected to the control bus, and connected to the first input terminal of the signal operation circuit through the control bus.

[0034] The welding current...

specific Embodiment 2

[0039] An adaptive welding machine characteristic control circuit of the present application is different from the specific embodiment 1 in that it also includes a no-load closed-loop control circuit,

[0040] The second output of the thermal arc control circuit is connected to one input terminal of the no-load closed-loop control circuit; the other input terminal of the no-load closed-loop control circuit is connected to the output feedback voltage terminal, and its output terminal is connected to the third input of the PI error amplifier circuit end.

[0041] The no-load closed-loop control circuit is used for summing and amplifying the output feedback voltage signal and the thermal arc start control signal to obtain a no-load closed-loop control signal for the PI error amplifier circuit.

[0042] The PI error amplification circuit performs summation and inversion operation on the operation result of the signal operation circuit, the output feedback current signal, and the n...

specific Embodiment 3

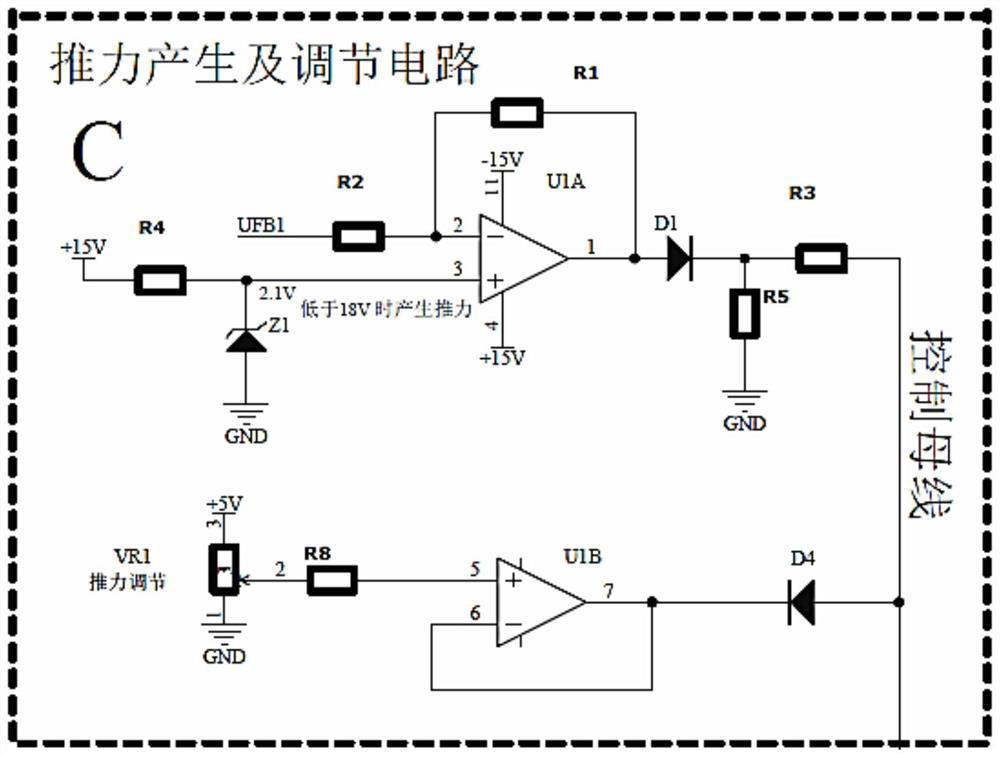

[0045] A thrust generation and adjustment circuit of an adaptive welding machine characteristic control circuit of the present application, such as figure 2 , 3 As shown, the thrust generation and adjustment circuit includes a thrust generation circuit and a thrust adjustment circuit, and the output thereof is connected to the control bus.

[0046]The thrust generating circuit includes an amplifying circuit U1A, the positive input terminal of the amplifying circuit U1A is connected to the first voltage setting terminal for providing a first setting voltage, and thrust is generated when the voltage is lower than the first setting voltage.

[0047] In this specific embodiment, the first set voltage terminal is composed of a resistor R4 and a voltage regulator tube Z1 in series, the other end of the resistor R4 is connected to the power supply, the other end of the voltage regulator tube Z1 is grounded, and the connection between the resistor R4 and the voltage regulator tube Z1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com