Polishing machine tool for building material processing

A technology of building materials and machine tools, applied in the field of polishing machine tools, can solve the problems of adjusting fixtures and abrasive tools, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

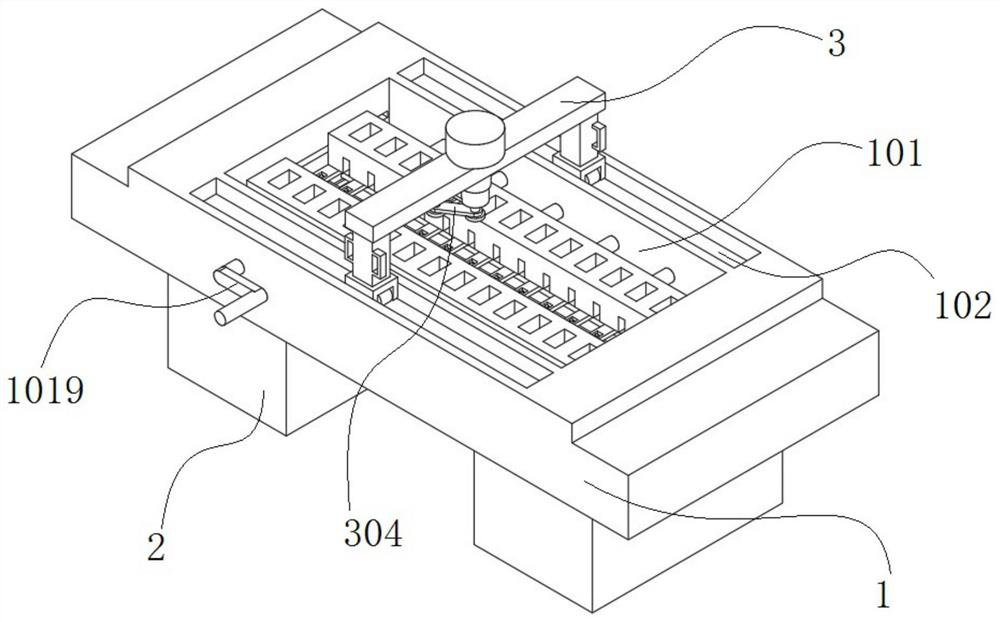

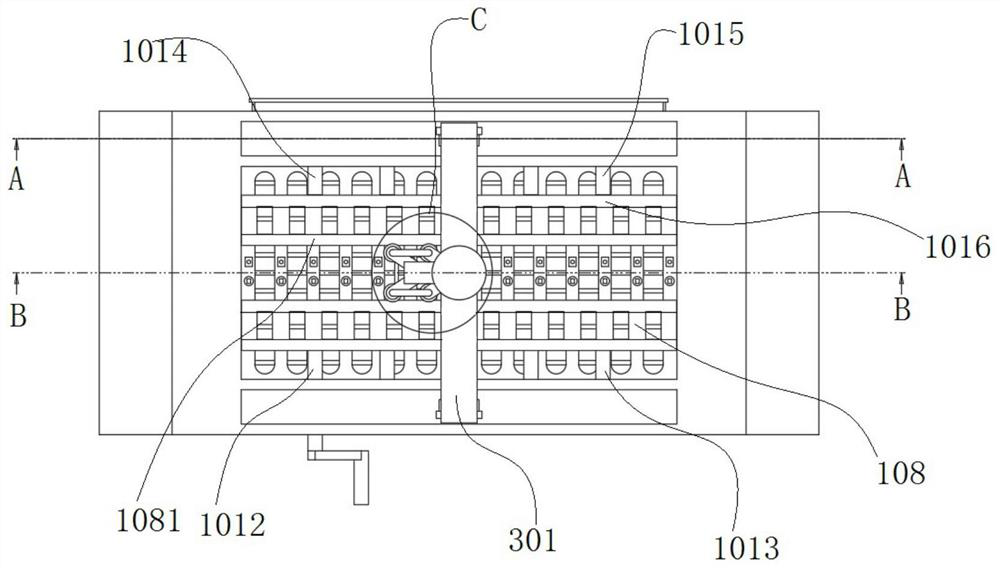

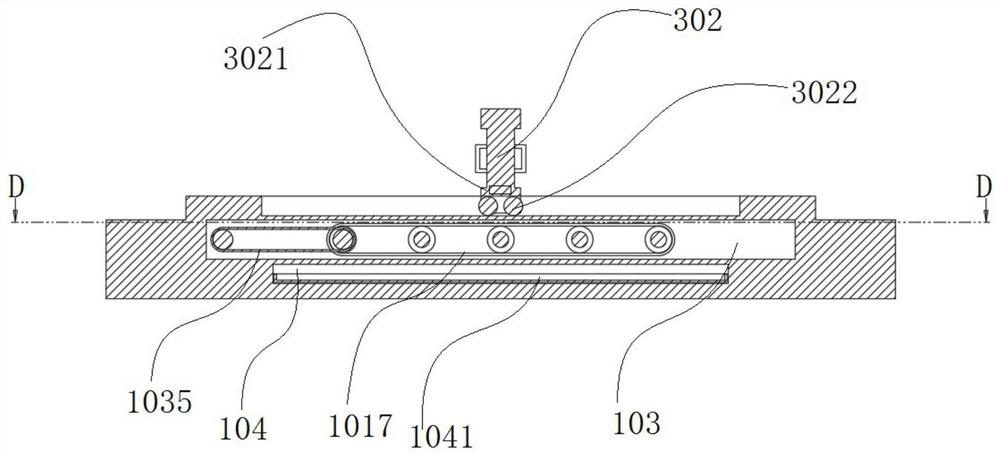

[0044] see Figure 1-8 As shown, the present embodiment is a working principle and a method of use of a polishing machine tool for building material processing:

[0045] It should be further explained that, in the polishing machine tool of the present invention, the model of the polishing motor 3032 and the adjusting motor is a PFM-36RP555 brushed DC motor, and the model of the microprocessor is a STM32F103RET6 type single-chip microcomputer, wherein the polishing motor 3032 and one of them are polished The emery wheel 3041 is snap-fitted and connected, and between some of the emery wheels 3041 and between the emery wheel 3041 and the emery wheel 3051, a transmission connection is carried out by installing a chain, so that the emery wheel 3041 and the emery wheel 3051 can work simultaneously; simultaneously, the emery frame 304 and the emery wheel 3051 A spring is installed between the folded rod-shaped structures of the frame 305, so that the grinding frame 304 and the polish...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com