Fiberboard paving and forming device

A molding device and fiberboard technology, applied in heating devices, lighting and heating equipment, dryers, etc., can solve the problems of inability to effectively ensure the overall quality of the molded fiberboard, poor use effect, and regulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

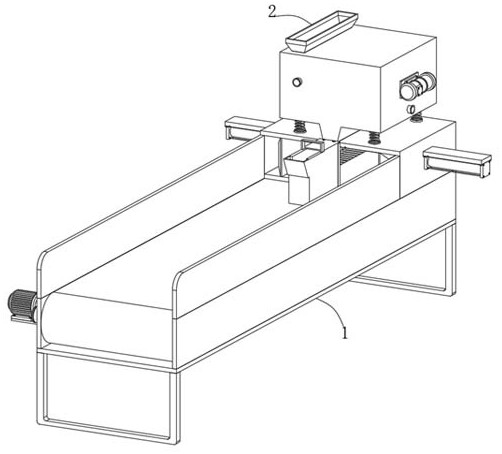

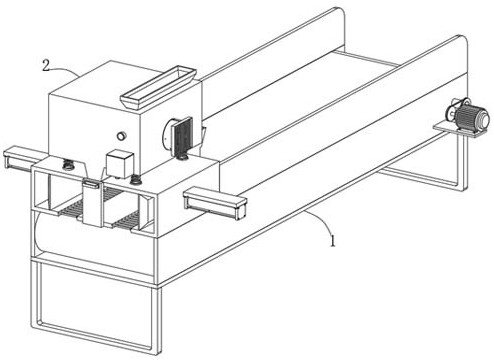

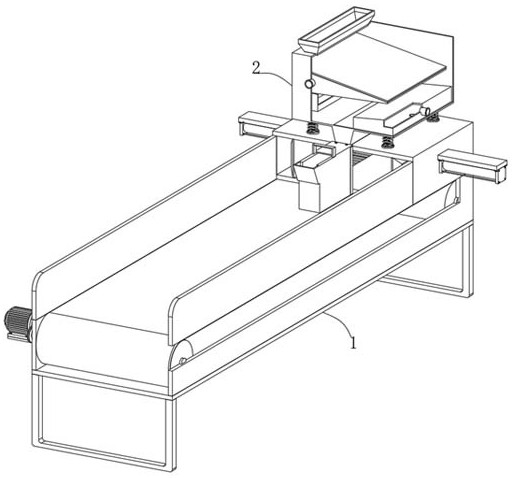

[0028] Embodiment one, with reference to Figure 1-9: A fiberboard pavement forming device, including a conveying mechanism 1 and a processing mechanism 2, the processing mechanism 2 is arranged on the top of the conveying mechanism 1, the processing mechanism 2 includes a bottom frame 201, and the setting of the bottom frame 201 facilitates the installation and setting of other functional parts of the equipment , the outer surfaces of both sides of the bottom frame 201 are fixedly connected with a fixed plate near the center, the setting of the fixed plate is convenient for the installation and setting of the oil cylinder 202, and the bottom of each fixed plate is fixedly connected with the oil cylinder 202 by bolts, and the setting of the oil cylinder 202 can effectively Adjust the moving position of the pressing plate 208, and then effectively carry out the extrusion and shaping process of the fiber material. The output ends of the two oil cylinders 202 slide through the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com