Vibration and noise reduction structure of steering wheel system

A system of vibration reduction and steering wheel technology, which is applied to the steering control, vehicle safety arrangement, handwheel and other directions installed on the car to achieve the effect of improving material utilization, reducing impact noise and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

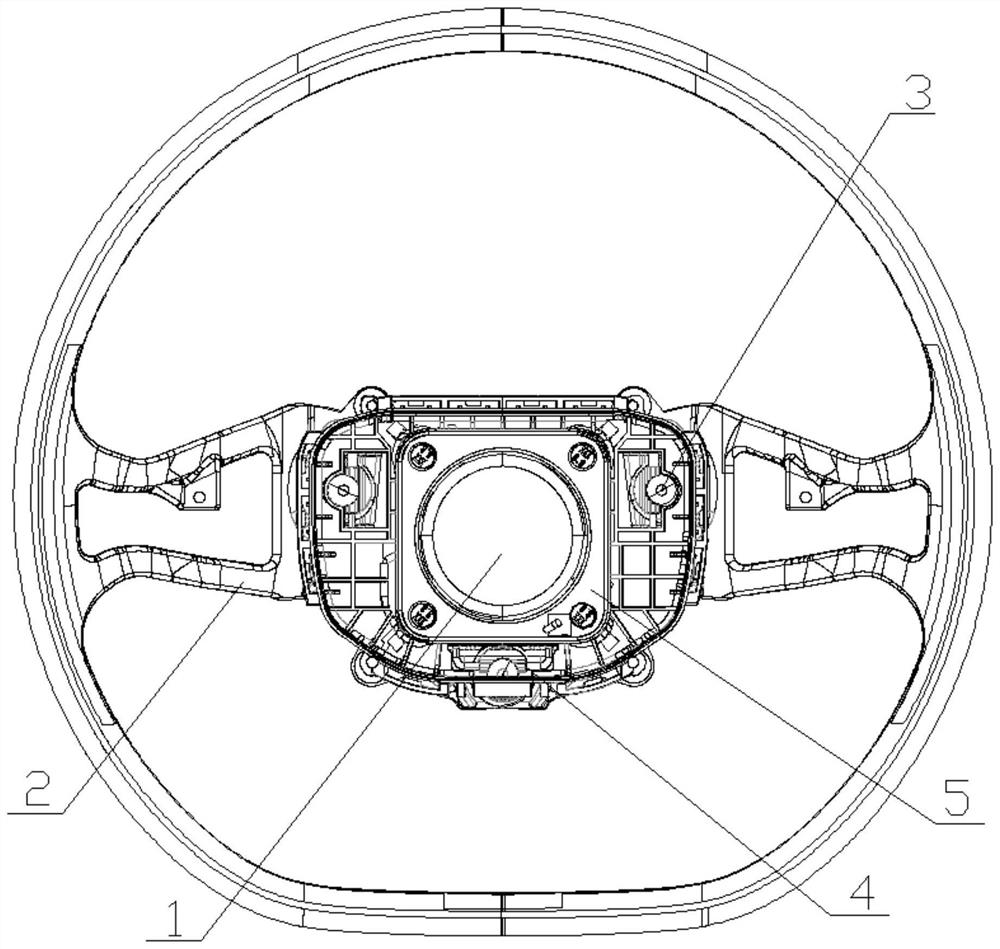

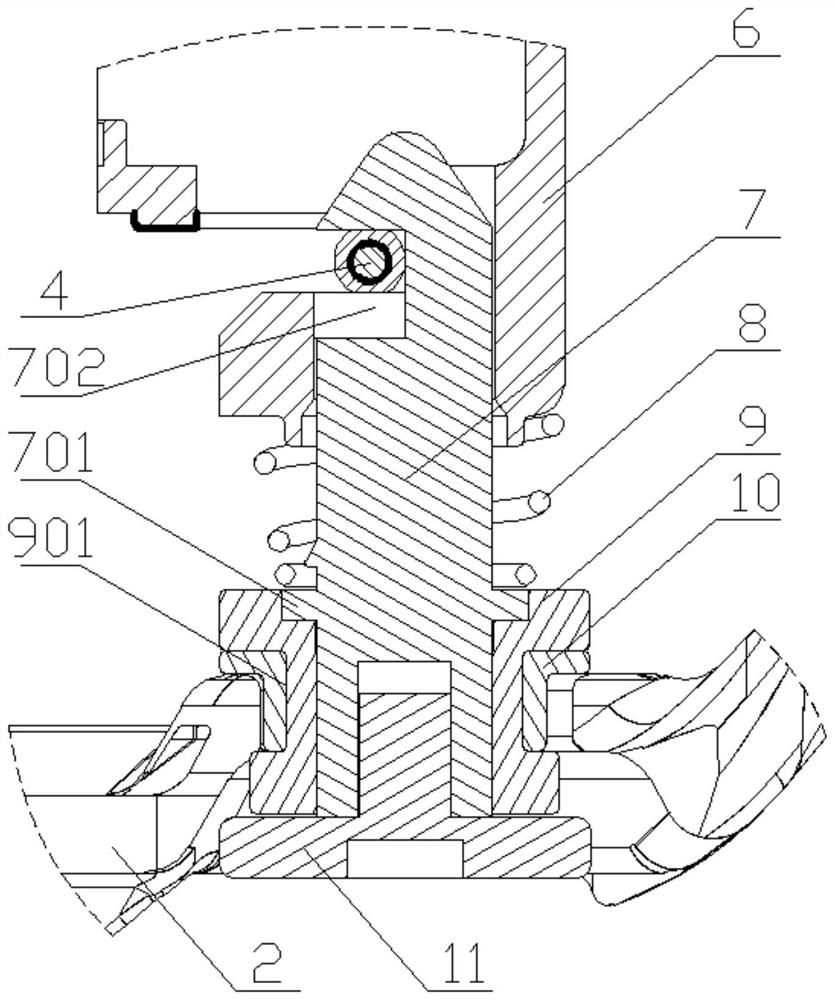

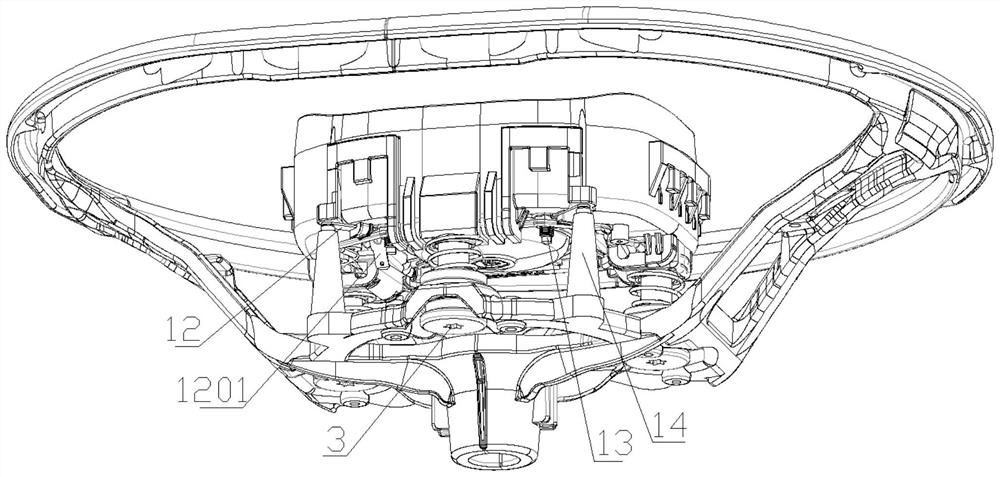

[0024] Such as Figure 1 ~ Figure 4 As shown, a steering wheel system vibration and noise reduction structure related to the present invention includes a steering wheel frame 2 and a driver airbag 1, and a plurality of vibration damping units 3 are installed on the steering wheel frame 2. In this embodiment, three vibration damping units 3 as an example and are respectively located at the 3, 6, and 9 o’clock directions of the steering wheel. The airbag housing 6 of the driver’s airbag 1 is elastically engaged with the steering wheel frame 2 through a clip spring 4 and a plurality of damping units 3 for The abnormal vibration borne by the steering wheel is transmitted to the driver's airbag 1 through the damping unit 3, so that the driver's airbag 1 acts as a shock absorber to absorb vibration.

[0025] The damping unit 3 includes a damping spring 8, a damping sleeve 9, a protective sleeve 10, a screw-type cover plate 11 and a damping bolt 7, wherein the damping sleeve 9 is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com