Material for relieving human body fatigue based on point area deformation recovery mechanism and preparation method of material

A technology of deformation recovery and point area, which is applied in the field of materials and its preparation, can solve the problems of backache, lumbar muscle strain, inability to really relieve physical fatigue, inability to massage while driving, etc., and achieve excellent shape stability and deformation recovery Good, not easy to permanently deform the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0090] The preparation method of the material for relieving human fatigue by using the point area deformation recovery mechanism of the present invention comprises the following steps:

[0091] In the first step, add the plasticizer, tackifying resin and one-half of the stabilizer to the first low-speed mixer, stir under normal pressure at 160°C, stir at a stirring speed of 40-60r / min, and stir for 50-60min to make the thickening The resin is completely melted and uniform.

[0092] In the second step, add the styrene block copolymer, filler, initiator and the remaining 1 / 2 stabilizer into the second low-speed mixer, stir under normal temperature and pressure, the stirring speed is 40-60r / min, and stir for 50- 60min, evenly enough.

[0093] The third step is to add the blended material of the first step above into the second low-speed mixer, and stir under normal temperature and pressure at a stirring speed of 40-60r / min, and stir for 60min until the material is completely abs...

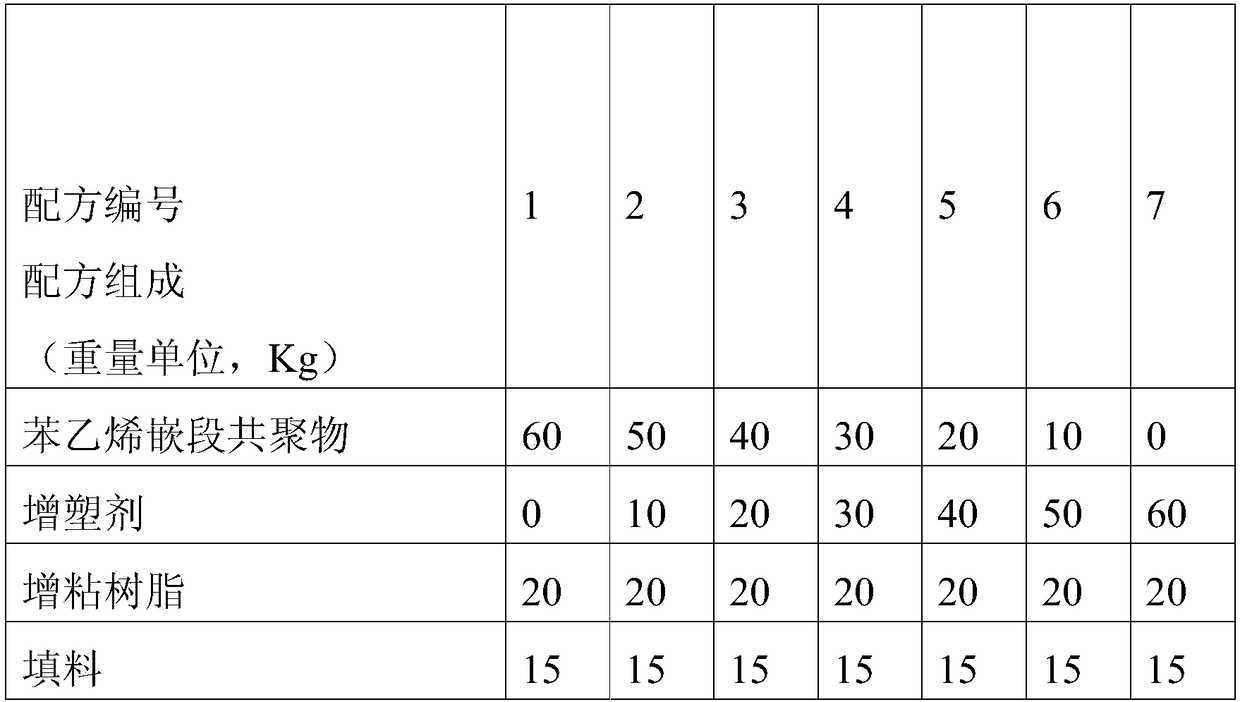

Embodiment 1

[0098] Styrene block copolymers and plasticizers with different mass ratios were weighed according to the formulas in Table 1, and the same mass ratios of tackifying resins, fillers, stabilizers, and initiators were also weighed according to the formulas in Table 1. Pick. According to the formula in Table 1, add plasticizers, tackifying resins and one-half of the stabilizer in different proportions into 1# low-speed mixer, stir under normal pressure at 160°C, stir at a speed of 40-60r / min, and stir for 50- 60min, so that the tackifying resin is completely melted and uniform. Then add the styrene block copolymer, filler, initiator and the remaining 1 / 2 stabilizer into the 2# low-speed mixer, stir under normal temperature and pressure, the stirring speed is 40-60r / min, stir for 50-60min, and mix well. That's it. Add the blended material of 1# mixer to 2# low-speed mixer, stir under normal temperature and pressure, the stirring speed is 40-60r / min, and stir for 60min until the ...

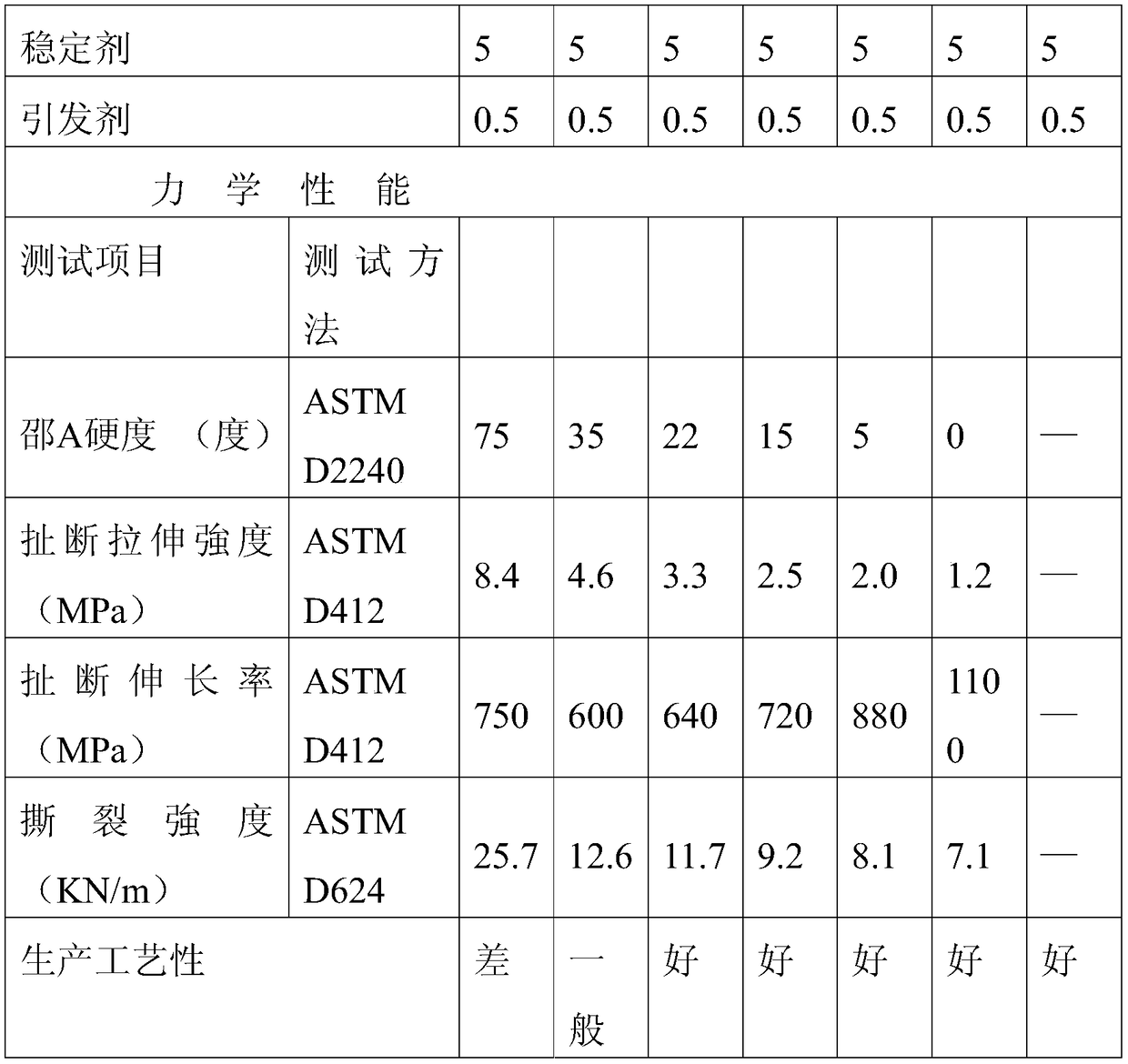

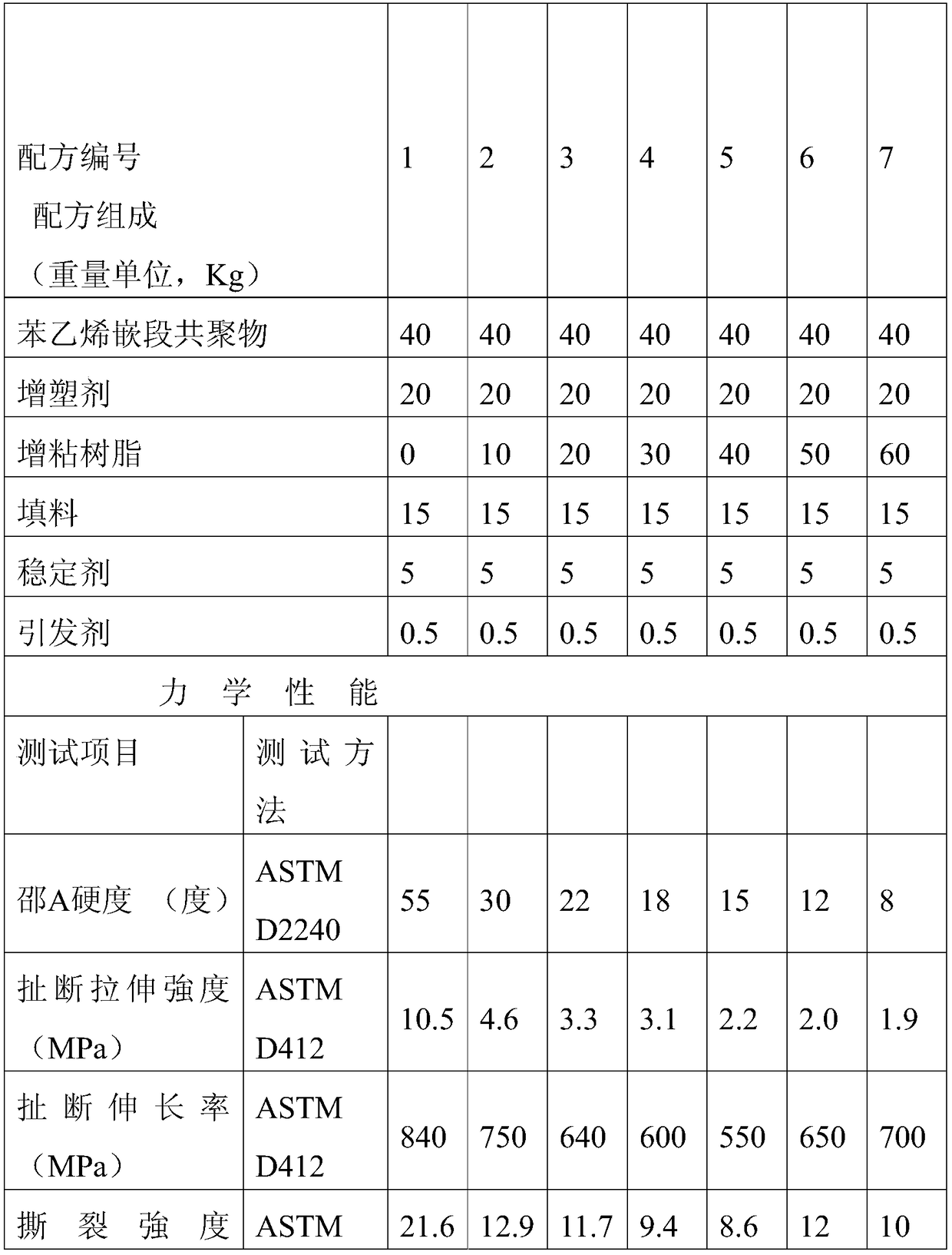

Embodiment 2

[0105] The No. 3 formulation in Table 1 was used as the basis, and the amount of tackifying resin was used as a variable for material preparation.

[0106] Styrene block copolymers, plasticizers, fillers, stabilizers, and initiators of the same mass ratio were weighed according to the formula in Table 2, and tackifying resins with different mass ratios were also weighed according to the formula in Table 2. Pick. According to the formula in Table 2, add plasticizers, tackifying resins and one-half of the stabilizer in different proportions into 1# low-speed mixer, stir under normal pressure at 160°C, stir at a speed of 40-60r / min, and stir for 50- 60min, so that the tackifying resin is completely melted and uniform. Then add the styrene block copolymer, filler, initiator and the remaining 1 / 2 stabilizer into the 2# low-speed mixer, stir under normal temperature and pressure, the stirring speed is 40-60r / min, stir for 50-60min, and mix well. That's it. Add the blended materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com