A core-shell tib 2 -fe 64 ni 36 Invarky Composite

A technology of tib2-fe64ni36 and composite materials, which is applied in the direction of additive manufacturing, etc., can solve the problems of poor wear resistance, low hardness, and difficulty in meeting the requirements of use, and achieve the effects of significant strengthening effect, improved hardness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further illustrated below through specific implementation examples. However, these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

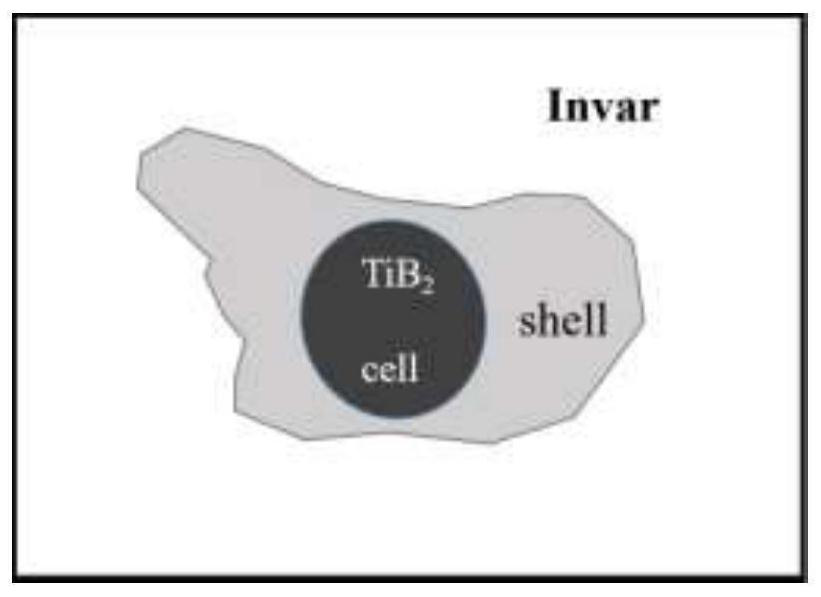

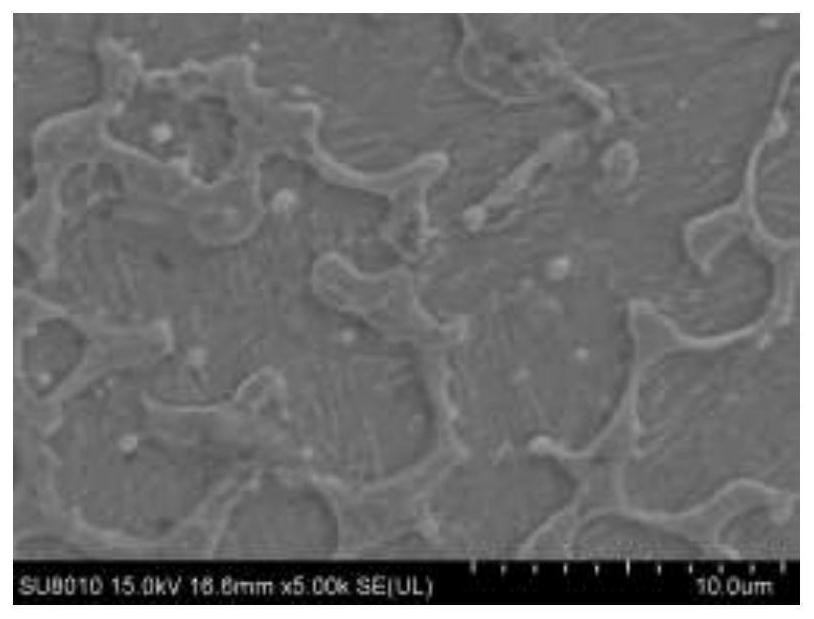

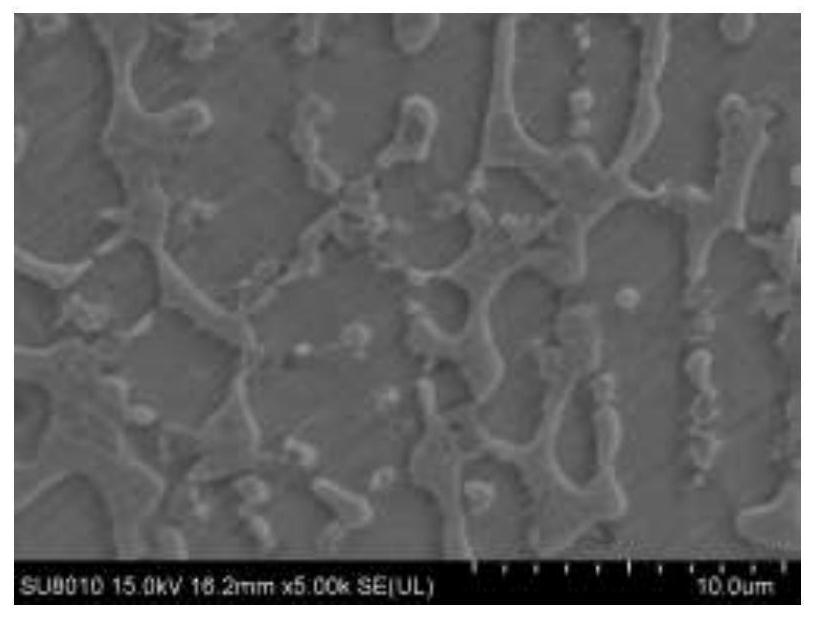

[0018] A core-shell TiB 2 -Fe 64 Ni 36 Invargi composites, the core-shell TiB 2 -Fe 64 Ni 36 Invar-based composites are made of TiB 2 The enhanced structure of the core-shell structure as the core and the Fe64Ni36 Invar alloy as the matrix; TiB 2 The reinforced structure of the core-shell structure as the core is evenly distributed in the matrix, and the reinforced phase with different structures can be formed by adjusting the added Ti / B atomic ratio.

[0019] The core-shell TiB 2 -Fe 64 Ni 36 The composition of the tile-based composite material is laser deposited from the mixed powder of elemental Fe, Ni, Ti and Fe-B alloy; the particle size of the mixed powder is 140-300 mesh, the shape is spherical, and the chemical compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com