Dyeing method of light, elastic and comfortable blended fabric and application of dyeing method

A dyeing method and a technology of blended fabrics, which are applied in dyeing methods, textiles and papermaking, etc., can solve the problems of uneven dyeing, surface stains of blended fabrics, and low color fastness, and achieve good same-color effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

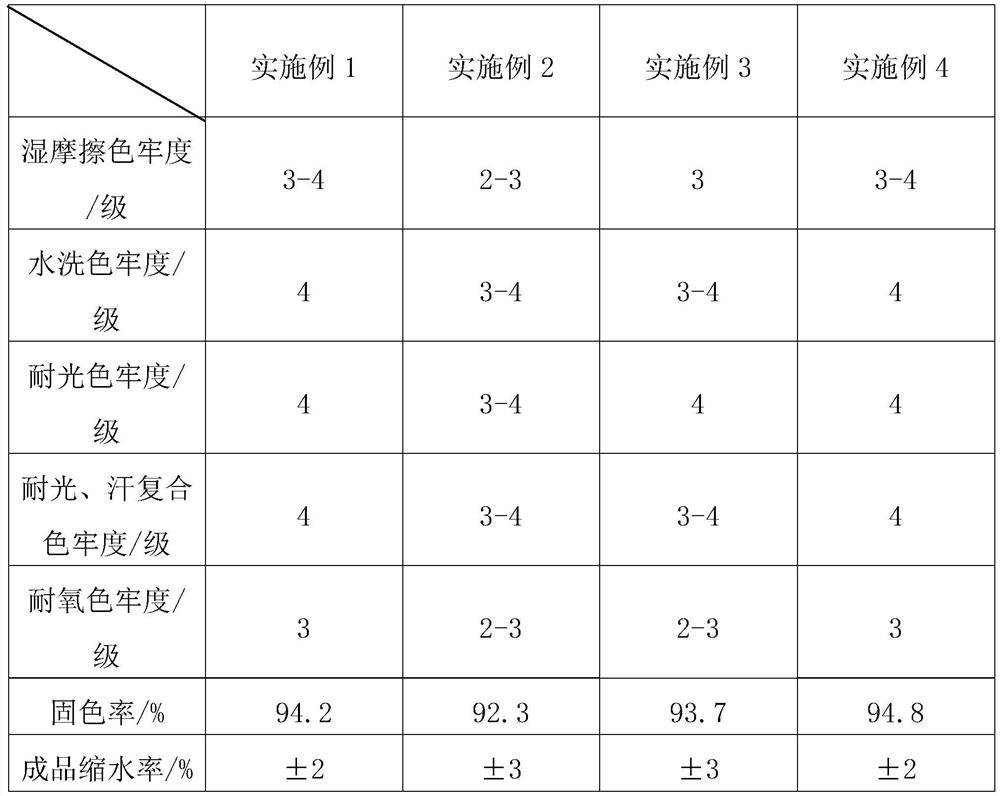

Examples

Embodiment 1

[0026] Use the mixed fabric with modal and spun silk in the warp direction and nylon in the weft direction as the fabric to be dyed for dyeing. The dyeing steps are as follows:

[0027] (1) Add acid dye, 1g / L leveling agent and 1g / L ammonium sulfate in water to make an acidic dye solution, keep the pH value of the acidic dye solution at 4-6, and the temperature is 30°C, add the dye to be dyed Fabric, bath ratio 1:10, heat preservation dyeing 5min; acid dyes include the following components: 4% owf acid K-PBL gray 200%, 1.2% owf acid K-GLS scarlet 150% and 3% owfK-GLN yellow 250%;

[0028] (2) Continue to heat up to 98°C at a heating rate of 2.5°C / min, keep warm and dye for 40 minutes, and then obtain a dyed fabric after cooling down, washing with water, and soaping;

[0029] (3) Add reactive dyes, 15g / l of soda ash and 15g / L of sodium sulfate in water to prepare a reactive dye solution, keep the pH value of the reactive dye solution at 10-12, and the temperature is 20°C, add ...

Embodiment 2

[0032] Use the mixed fabric with modal and spun silk in the warp direction and nylon in the weft direction as the fabric to be dyed for dyeing. The dyeing steps are as follows:

[0033] (1) Add acid dye, 2g / L leveling agent, 2g / L ammonium sulfate and 0.5g / L light stabilizer to the water to make an acidic dye solution. The light stabilizer is light stabilizer 783 to keep the acidity The pH value of the dyeing solution is 4-6, the temperature is 40°C, add the fabric to be dyed, the bath ratio is 1:15, and keep warm for 1 minute; the dosage of each component of the acid dye is as follows: 3% owf acid K-PBL ash 200%, 1.5% owf acid K-GLS scarlet 150% and 4% owf K-GLN yellow 250%;

[0034] (2) Continue to heat up to 108°C at a heating rate of 3.5°C / min, keep warm and dye for 30 minutes, and then obtain a dyed fabric after cooling down, washing with water, and soaping;

[0035] (3) Add reactive dyes, 20g / l soda ash and 20g / L sodium sulfate to water to prepare a reactive dye solution...

Embodiment 3

[0038] Use cotton in the warp direction and nylon and silk in the weft direction as the fabric to be dyed for dyeing. The dyeing steps are as follows:

[0039] (1) Add acid dye, 3g / L leveling agent, 3g / L ammonium sulfate and 2g / L photostabilizer in water to configure an acidic dye liquor, the photostabilizer is photostabilizer 119 and photostabilizer Keep the pH value of the acid dye solution at 4-6, and the temperature is 35°C, add the fabric to be dyed, the liquor ratio is 1:10, and keep warm for 3 minutes; the dosage of each component of the acid dye is as follows: 5 % owf Acid K-PBL Gray 200%, 1.0% owf Acid K-GLS Scarlet Red 150% and 2% owf K-GLN Yellow 250%;

[0040] (2) Continue to heat up to 90°C at a heating rate of 2.0°C / min, keep warm and dye for 50 minutes, then cool down, wash with water, and soap to obtain a dyed fabric;

[0041] (3) Add reactive dyes, 25g / l of soda ash and 25g / L of sodium sulfate in water to prepare a reactive dye solution, keep the pH value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com