Steel corrugated culvert pipe structure with EPS (Expandable Polystyrene) load reducing plates

A corrugated culvert pipe and load-reducing plate technology, applied in the fields of railway and highway tunnel engineering, can solve problems such as large load and easy deformation, and achieve the effect of prolonging life, protecting structural safety and strong durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

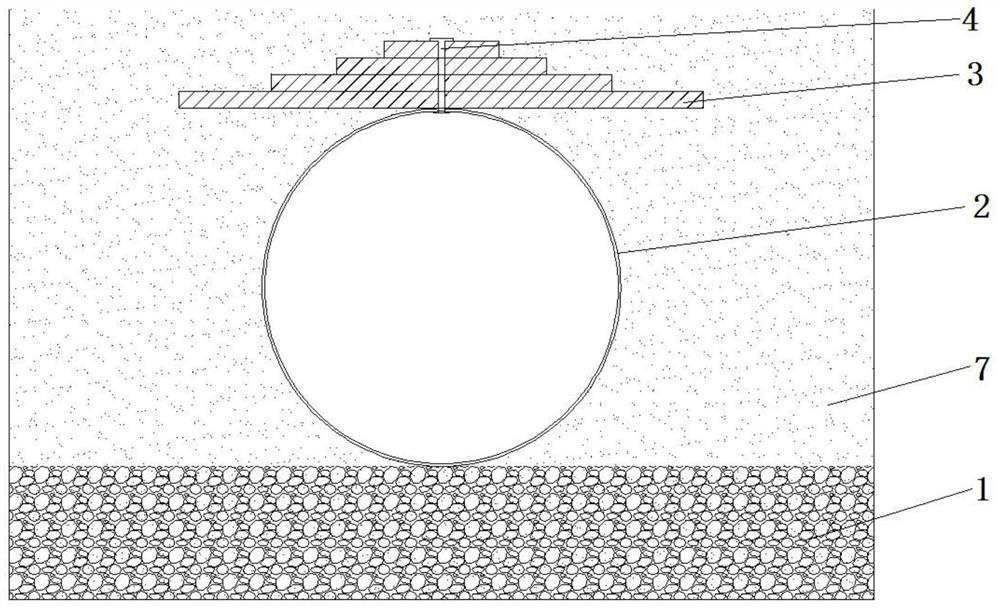

[0023] see figure 1 , this embodiment discloses a steel corrugated culvert structure with EPS load-relief plates, including a foundation, on which a sand and gravel cushion 1 is laid, the thickness of the sand and gravel cushion 1 is 50 cm, and the gravel of the sand and gravel cushion 1 is the largest The particle size is less than 10mm, and the compaction degree of the sand and gravel cushion is greater than 97%; the steel corrugated culvert 2 is set on the sand and gravel cushion 1, and the upper end of the steel corrugated culvert 2 is provided with a horizontal EPS load-reducing body 3, and the horizontal EPS load-reducing body 3 Including four stacked EPS veneers, the thickness of the four stacked EPS veneers is the same, 20cm, the width of the bottom EPS veneer is greater than the maximum outer diameter of the steel corrugated culvert pipe, and the four EPS veneers are from top to bottom The bottom is stacked in a ladder shape, in which the upper EPS board is narrow, an...

Embodiment 2

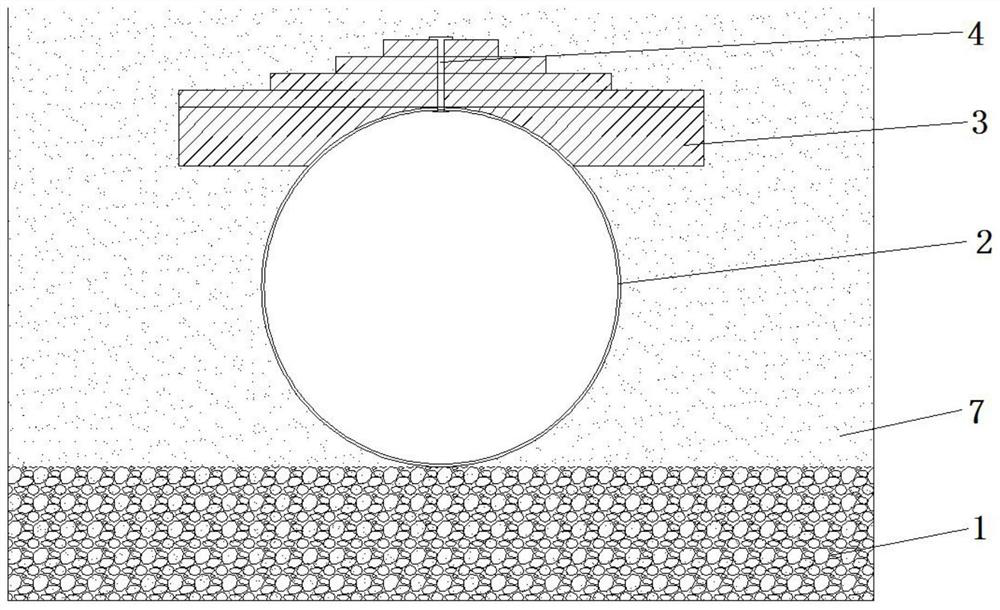

[0027] see figure 2 , and the difference from Example 1 is that the transverse EPS load-relief body 3 includes five stacked EPS veneers, wherein the thickness of the four stacked EPS veneers on the upper layer is the same, all of which are 20 cm, and their arrangement is the same as that of the embodiment The same as in 1, stacked from top to bottom in a ladder shape, the EPS veneer on the upper layer is narrow, and the EPS veneer on the lower layer is wide; there is also a thickened EPS veneer on the bottom layer, its thickness is greater than 40cm, and the thickened EPS veneer The lower end surface of the veneer is provided with an arc-shaped stabilizing groove, and the stabilizing groove fits with the arc top of the upper end of the steel corrugated culvert 2, so as to ensure that the entire horizontal EPS load-reducing body 3 is not easy to overturn after filling.

Embodiment 3

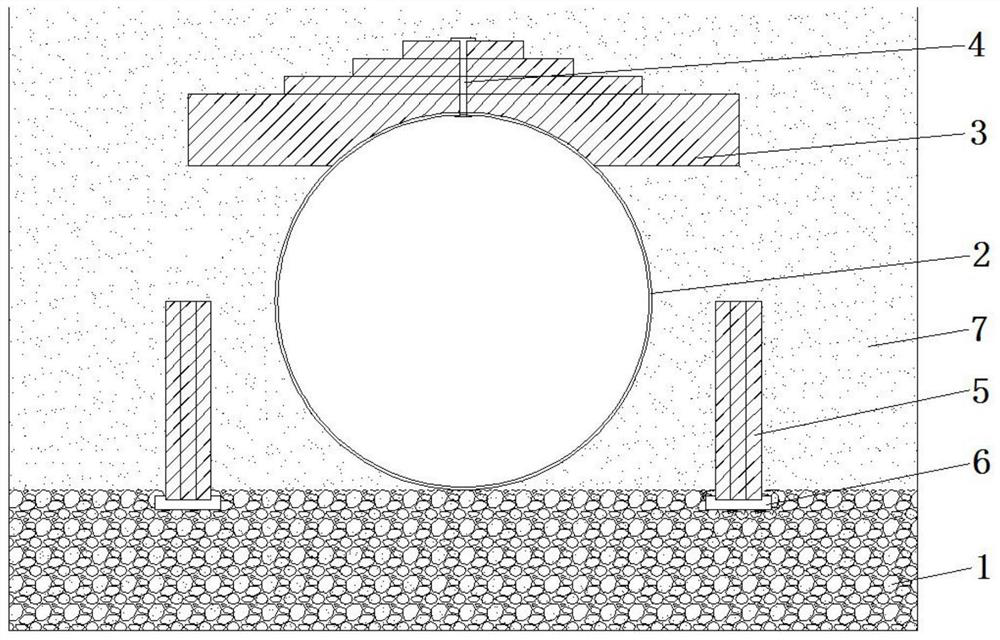

[0029] see image 3 , the difference from Embodiment 1 or 2 is that a vertical EPS load-reducing body 5 is arranged on both sides of the steel corrugated culvert 2, and the vertical EPS load-reducing body 5 includes three equal-sized EPS veneers, and the vertical EPS load-reducing body The body 5 is fixed by the base 6 embedded in the gravel cushion 1, and the height of the vertical EPS lightening body 5 is greater than the radius of the steel corrugated culvert 2. In this embodiment, the upper edge of the vertical EPS lightening body 5 is at The horizontal diameter line of steel corrugated culvert pipe 2. The vertical EPS load-reducing body 5 is used to reduce the load on both sides of the steel corrugated culvert 2, reduce the horizontal pressure of the fill on both sides of the steel corrugated culvert 2, and prolong the life of the culvert.

[0030] The test proves that the unloaded steel corrugated culvert shows the characteristics of rigid pipe at the lower stage of fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness range | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com