Fabricated foundation pit slope supporting structure

A supporting structure and prefabricated technology, which can be used in infrastructure engineering, sheet pile walls, excavation, etc., can solve the problems of unusable permafrost, low supporting rigidity, easy to cause pollution, etc., to improve resource utilization, The effect of improving support rigidity and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

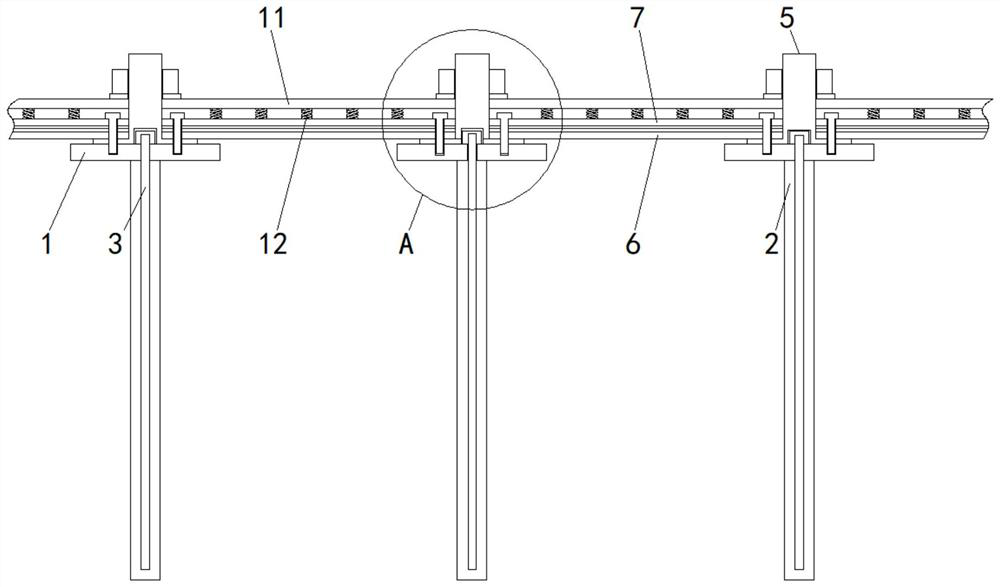

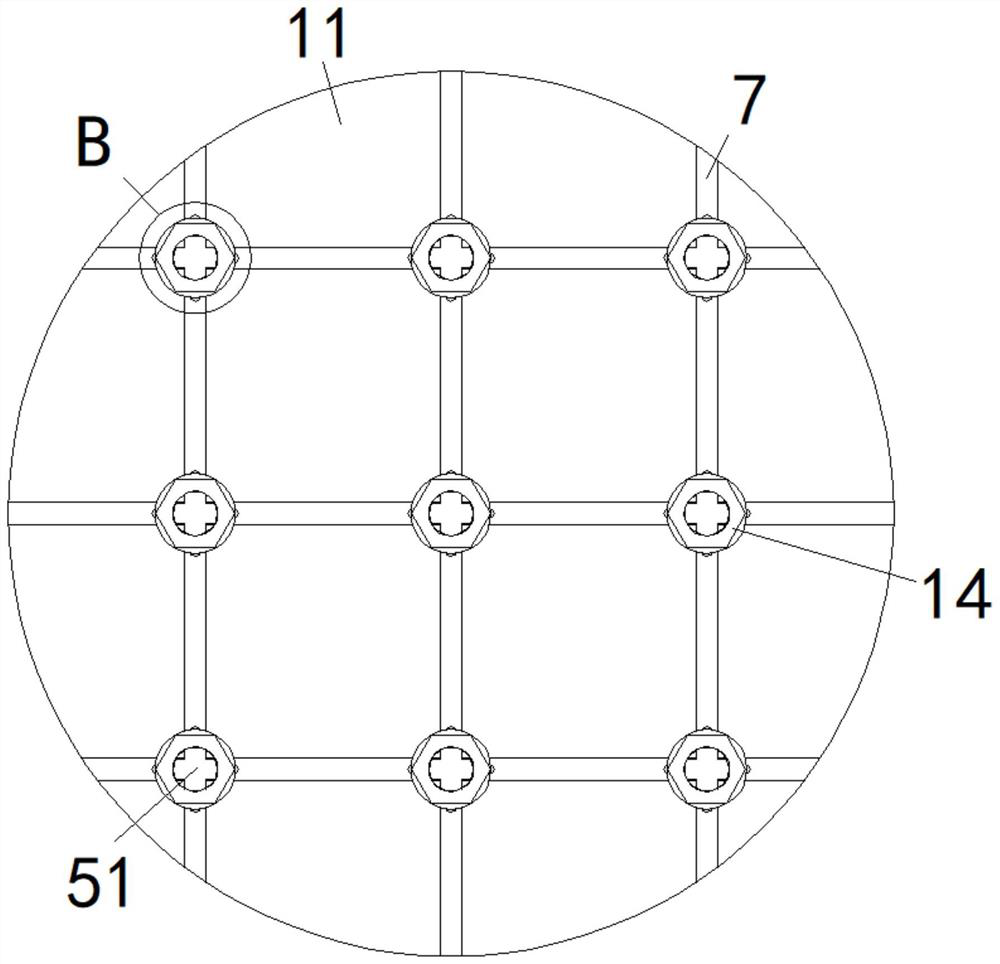

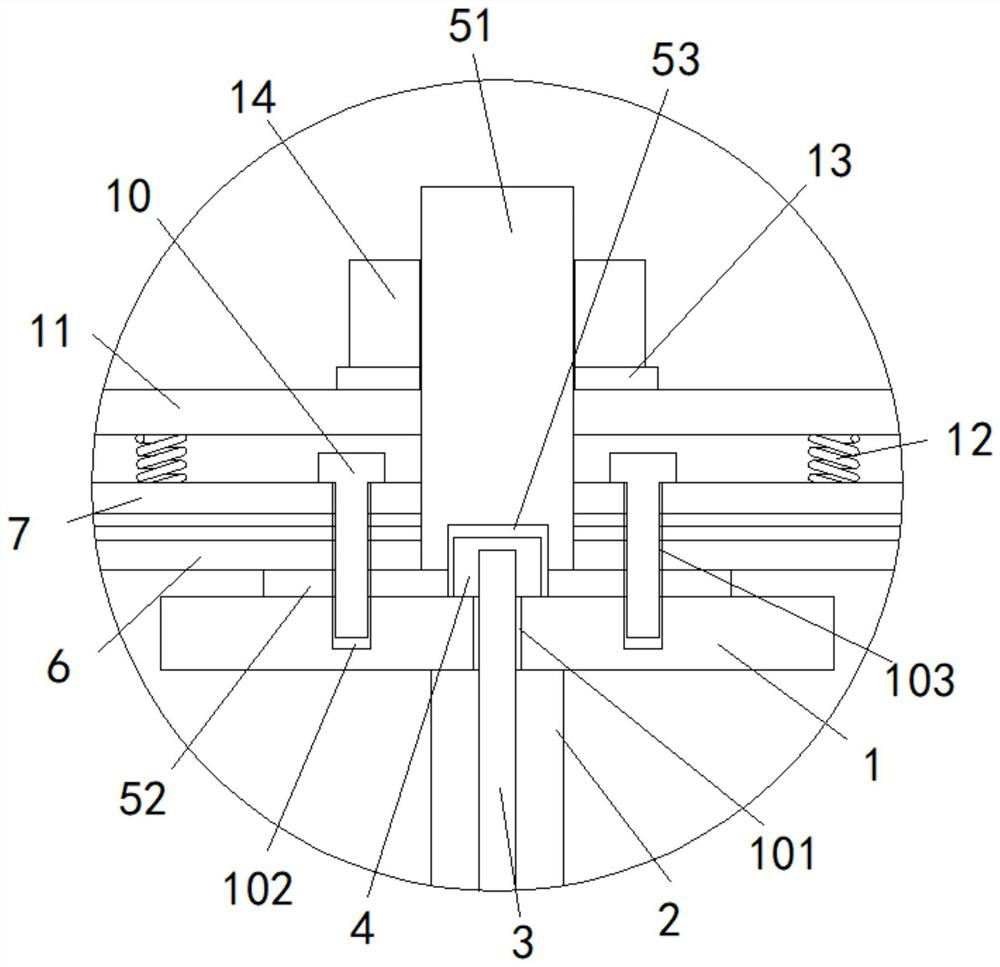

[0024] see Figure 1~5 , in an embodiment of the present invention, a prefabricated foundation pit slope support structure includes a number of fixed plates 1, the lower ends of several fixed plates 1 are fixedly connected with anchor piles 2, and the number of anchor piles 2 The interior is fixedly connected with the anchor cable 3 that runs through the fixed plate 1, and several fixed plates 1 are distributed equidistantly in an array. The anchor cable 3 is steel bar, the anchor pile 2 is concrete, and the anchor pile 2 and the anchor cable 3 are poured in one piece of concrete. , the exteriors of several anchor cables 3 are all fixedly connected with the limit block 4 located at the upper end of the fixed plate 1, and the upper ends of several fixed plates 1 are all movably connected with the fixed column 5 located at the outside of the limited block 4, and the fixed column 5 includes a column body 51, the lower end of the column body 51 is fixedly connected with a flange 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com