Buckle type connecting structure and application thereof

A connection structure and buckle-type technology, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems of cumbersome construction technology, difficulty in ensuring the quality of connection parts, and slow construction speed, etc. The effect of small workload, saving learning cost and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

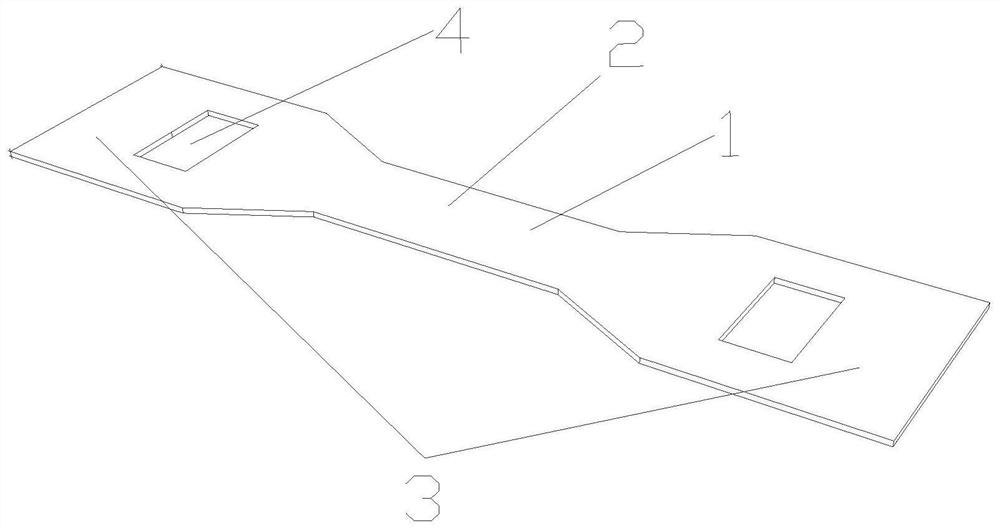

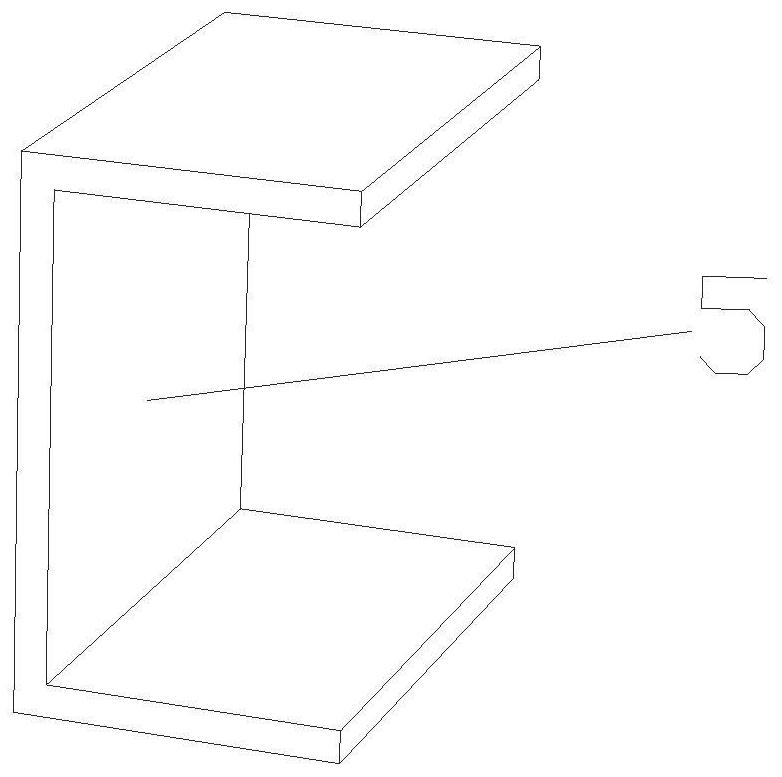

[0056] A snap-fit connection structure provided by the present invention is arranged between boards or boards and beams, and is used to connect boards or boards and beams as a whole. It includes a first connecting piece 1, the first The connecting piece 1 includes a first connecting part 2 and a second connecting part 3 located at both ends of the first connecting part 2, and first through holes 4 are respectively opened on the second connecting parts 3, and in the first through holes 4 A second connecting piece 5 is inserted, and the second connecting piece 5 buckles the first connecting piece 1 and the plate or beam to connect them together.

[0057] Further, in this embodiment, as figure 1 As shown, the two ends of the first connecting part 2 respectively extend outwards to connect with the second connecting part 3, and the connecting part between the first connecting part 2 and the second connecting part 3 is in the shape of a bell mouth, increasing the second Stress st...

Embodiment 2

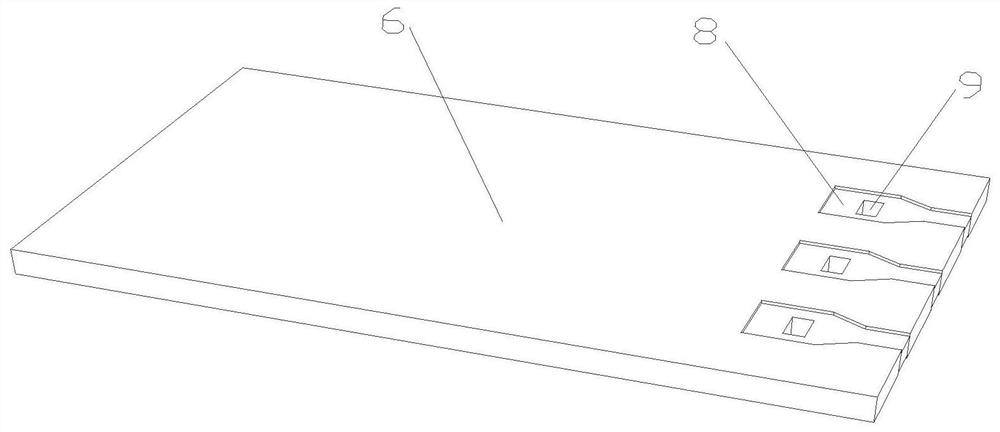

[0060] The prefabricated panel structure adopting the above snap-fit connection structure, such as Figure 4-Figure 7 As shown, it includes a first prefabricated panel 6 and a second prefabricated panel 7. The first prefabricated panel 6 and the second prefabricated panel 7 are placed side by side, and the connecting structure is located between the two. On the first prefabricated panel 6 The upper and lower end faces of the second prefabricated plate 7 facing each other are respectively provided with first grooves 8, and a second through hole 9 is provided between the first grooves 8 opened on the upper and lower end faces. The first connecting piece 1 is installed in the first groove 8 of the prefabricated plate 6 and the second prefabricated plate 7, and the first through hole 4 of the first connecting piece 1 is connected to the second through hole of the second connecting part 3. Corresponding to the hole 9, the second connecting piece 5 is inserted into the second thro...

Embodiment 3

[0074] The prefabricated slab-beam integrated structure adopting the above snap-fit connection structure, such as Figure 12-Figure 15 As shown, it includes a first prefabricated panel 6, a second prefabricated panel 7 and a prefabricated beam 10, such as Figure 9 and Figure 11 As shown, the two shoulders of the prefabricated beam 10 are respectively provided with steps 11, and the L-shaped connectors 12 are seated on the steps 11, specifically, as Figure 10 As shown, the L-shaped connector 12 is a prefabricated angle steel, and the first prefabricated panel 6 and the second prefabricated panel 7 are respectively installed on the L-shaped connector 12 on both sides of the prefabricated beam 10. The first prefabricated The upper end surfaces of the plate 6 and the second prefabricated slab 7 close to the side of the prefabricated beam 10 are respectively provided with first grooves 8, and the first grooves 8 opened on the upper end surfaces respectively penetrate the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com