Low-GI soft material suitable for 3D printing, preparation method of low-GI soft material, low-GI biscuit and preparation method of low-GI biscuit

A 3D printing and soft material technology, which is applied in the field of biscuit preparation, low GI soft material and soft material preparation, can solve the problems of uneven printing, poor material support forming performance, poor forming stability of printing raw materials, etc., to meet the needs of special groups of people Needs, flexible design, improved functionality and the effect of product added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

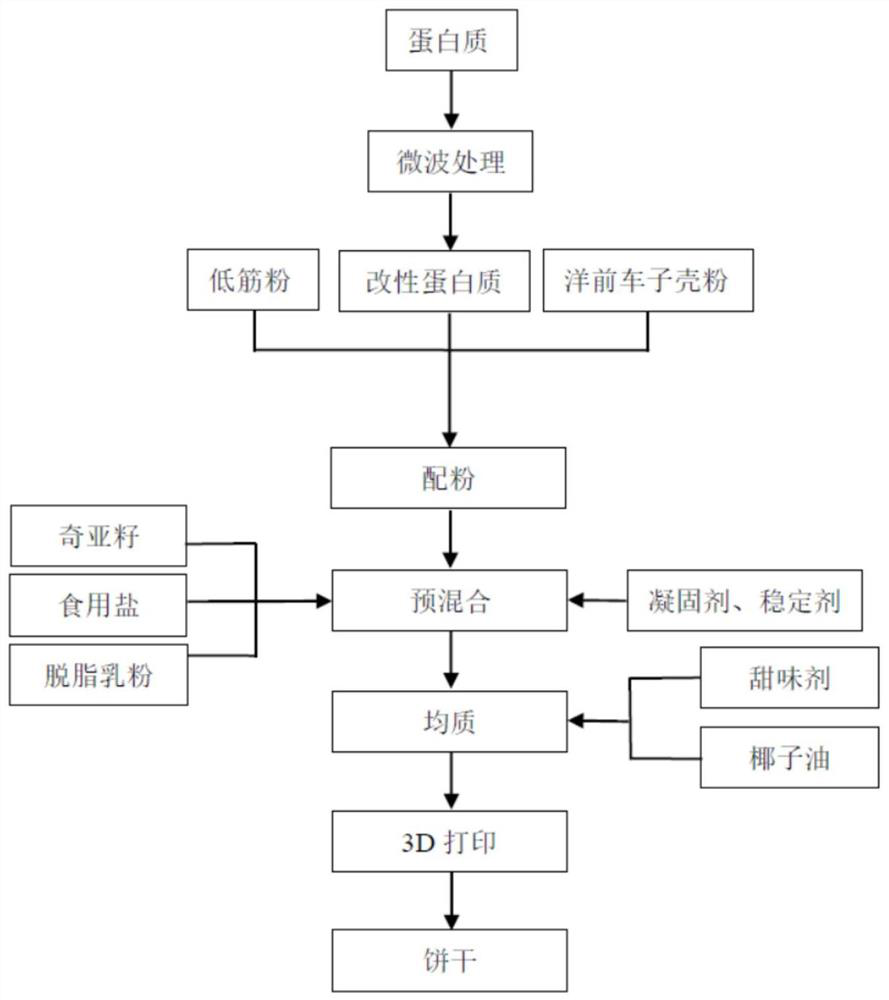

[0029] A method for preparing a low GI soft material, comprising the steps of:

[0030] Preparation of protein composite powder: firstly, the raw protein is modified by the microwave-assisted method to obtain the modified protein; the modification of the protein by the microwave-assisted method is as follows: dissolve the protein in PBS buffer solution with a pH of 7.0, stir Uniform, placed in a microwave oven, where the microwave parameters are: microwave power 300W-700W, microwave time 2min-10min, solid-liquid ratio 1:5-11.

[0031] Then, the obtained modified protein is mixed with low-gluten flour and cypress husk powder in proportion, mixed evenly, and dried to obtain protein composite powder.

[0032] In terms of weight percentage, the ratio of modified protein to low-gluten flour and foreign-made car shell powder is: 45%-55% of modified protein, 5%-10% of foreign-made car shell powder, and 5% of low-gluten carton powder -10%. In this embodiment, modified protein, low-g...

Embodiment 1

[0042] Accurately weigh 20g of protein and dissolve it in PBS buffer solution with a pH of 7.0, stir evenly, and place it in a microwave oven. protein;

[0043] Proportionately mix the low-gluten flour, the former carcass shell powder and the modified protein to obtain the protein composite powder; in terms of weight percentage, 55% of the modified protein, 10% of the former carton shell powder, and 10% of the low-gluten flour ;

[0044] Protein compound powder is mixed with chia seeds, edible salt, skimmed milk powder, coagulant, and stabilizer in proportion, in which chia seeds are 10%, edible salt is 1%, skim milk powder is 0.5%, and coagulant is 0.02% %, stabilizer 3%; coconut oil and sweetener are mixed in proportion to obtain a mixed composite powder;

[0045] According to the percentage by weight, 10% of sweetener, 5% of coconut oil, 30% of water are added, after mixing, a homogenizer is used to make a stable solution, and the mixed composite powder is evenly stirred ...

Embodiment 2

[0047] Accurately weigh 25g of protein and dissolve it in PBS buffer solution with a pH of 7.0, stir evenly, and place it in a microwave oven. protein;

[0048] Mix the low-gluten flour, the husk powder and the modified protein in proportion, wherein 50% of the modified protein, 8% of the husk powder and 8% of the low-gluten flour are mixed evenly to obtain a protein composite powder;

[0049] Mix the obtained protein composite powder with chia seeds, edible salt, skim milk powder, coagulant and stabilizer in proportion, wherein 15% of chia seeds, 1.5% of edible salt, 1.0% of skim milk powder, 0.02% of coagulant, 3% stabilizer to obtain a mixed composite powder.

[0050] Mix coconut oil and sweetener in proportion, including 15% sweetener, 10% coconut oil, and 40% water. After mixing, use a homogenizer to make a stable solution, and stir it with the mixed compound powder to form a suitable 3D solution. The printed food soft material, that is, low GI soft material, is injecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com