Method capable of automatically smearing coupling agent on ultrasonic probe

A technology of ultrasonic probe and coupling agent, which is applied in the directions of ultrasonic/sonic/infrasonic diagnosis, ultrasonic/sonic/infrasonic Permian technology, ultrasonic/sonic/infrasonic image/data processing, etc. Intelligent control of spraying couplant, inconvenient use by medical staff, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Such asFigure 6 As shown, the present invention also provides a method of automatically discomiting a coupling agent on an ultrasonic probe, using the above device, including the following steps:

[0043]Step 1: When the ultrasonic probe is placed on the patient, the substrate 2-8 in the pressure sensor extruded the cantilever beam 2-3, resulting in a change in the resistance value of strain sheet 2-2 and is considered to be inspected for the patient, and the microcontroller 1 -1 Control air pump module 1-2 spray a small amount of coupling agent; the single-chip unit 1-1 calculates the thickness of the fat according to the data monitored by the ultrasonic probe module 1-4, and calculates the amount of spray coupling agent according to the fat thickness, and the formula of the fat thickness is H = (t * v) / 2, where h indicates the fat thickness, T represent time, V represents the propagation speed of ultrasonic waves; the formula of the spray coupling dose L1 is L1 = D * x * h, w...

Embodiment 2

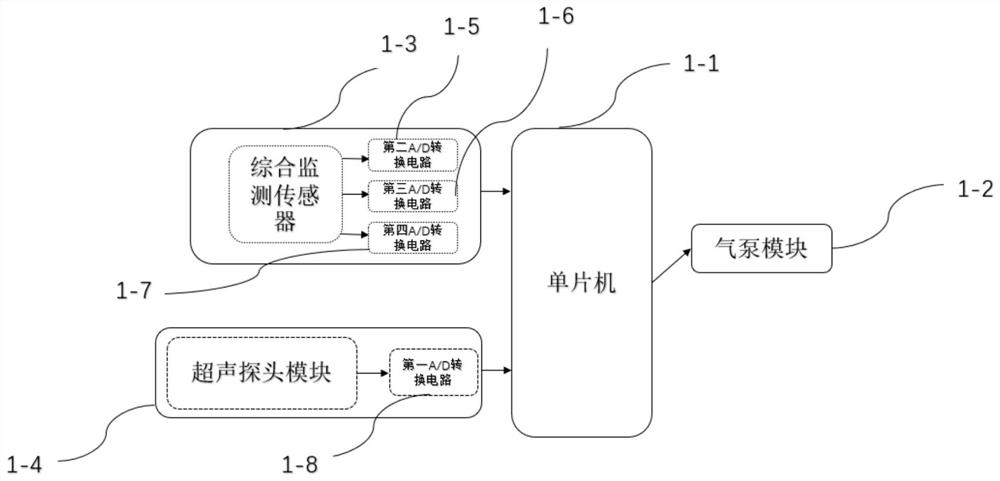

[0048]Such asFigure 3-5As shown, an apparatus capable of moving a coupling agent on an ultrasonic probe includes an ultrasonic probe module 1-4, an integrated monitoring sensor 1-3, a single chip 1-1, a gas pump module 1- 2, nozzle 3-1; the ultrasonic probe module 1-4, integrated monitoring sensor 1-3, air pump module 1-2 is connected to single chip 1-1; the gas pump module 1-2 passes through the hose and spout 3- 1 connection.

[0049]The ultrasonic probe module 1-4 includes generators and receivers that transmit ultrasonic waves to the patient, the receiver receives an ultrasonic echo signal, and the ultrasonic echo signal is converted into a number through the first A / D conversion circuit 1-8. The ultrasonic echo signal is transmitted to the single-chip unit 1-1 again to perform calculation processing.

[0050]Further, the single-chip unit 1-1 extracts the digital ultrasonic echo signal and identifies it, identifies that the individual fat layers under the skin received by the ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com