Tubular feeding mud-water separation environment-friendly treatment device

A mud-water separation and environmental protection treatment technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of poor separation effect, inconvenient transportation, and large loss of facilities and resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

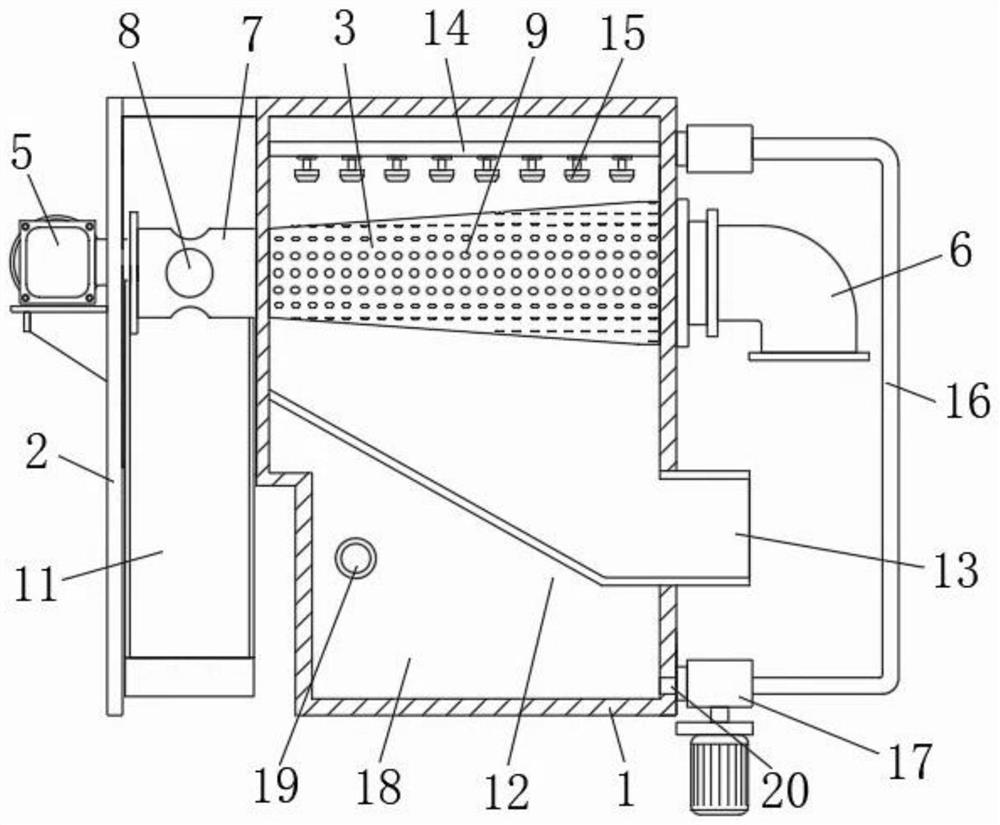

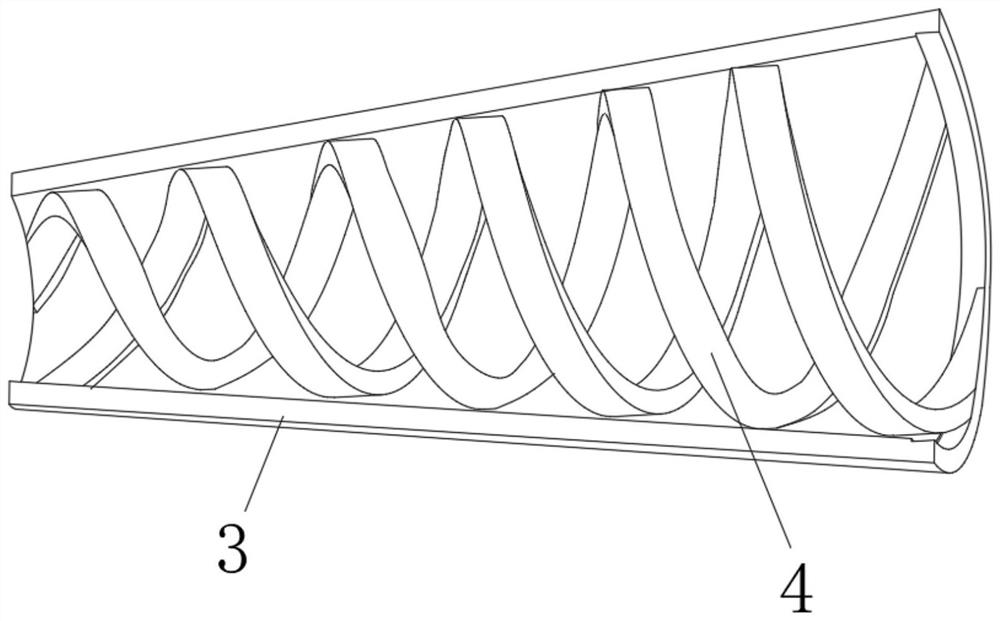

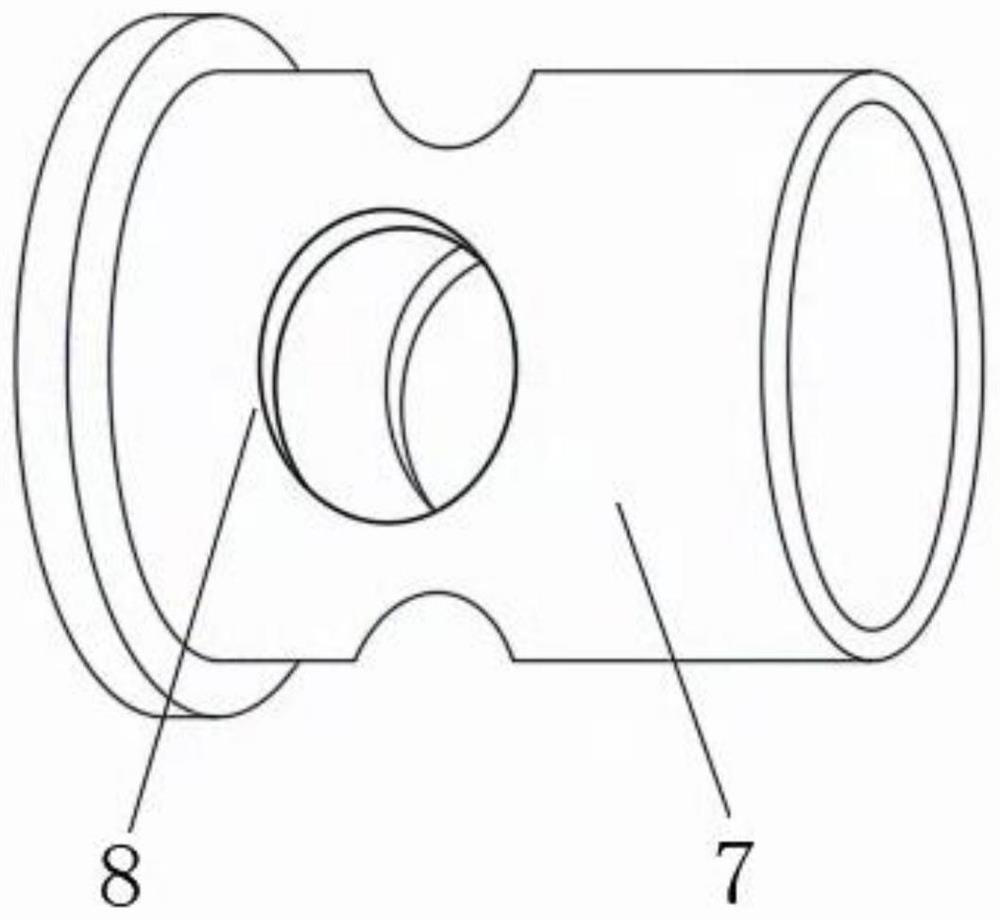

[0023] see Figure 1-3 As shown, the present invention provides a technical solution: an environmental protection treatment device for separating mud and water with tubular feeding, including a cavity 1 and a frame 2, a round tube 3 is fixed inside the cavity 1, and one end of the round tube 3 is fixedly connected with a mud inlet 6. The mud inlet 6 is on the outside of the cavity 1, and the inside of the round pipe 3 is provided with a screw extruded part 4, and the side of the spiral extruded part 4 away from the mud inlet 6 is fixed with a connecting pipe 7, and the surface of the connecting pipe 7 is provided with Mud discharge port 8, the other end of connecting pipe 7 is provided with drive motor 5, and the surface of driving motor 5 and frame 2 is fixed, and the bottom end of connecting pipe 7 is provided with mud discharge plate 11, and the surface of mud discharge plate 11 and frame 2 is fixed, discharges The surface of the mud plate 11 is provided with a mud discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com