Multifunctional cut tobacco cleaning system and method

A cleaning system and multi-functional technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of low utilization rate, long idle time of cleaning robots, and inability to judge the cleanliness of shredded tobacco boxes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

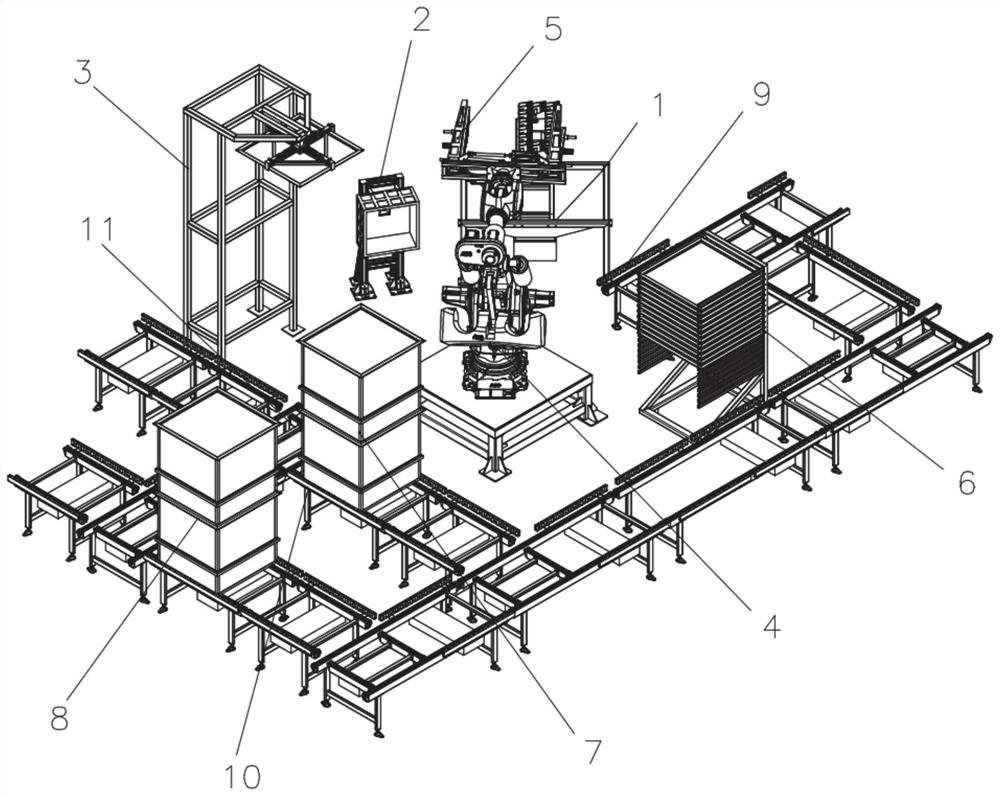

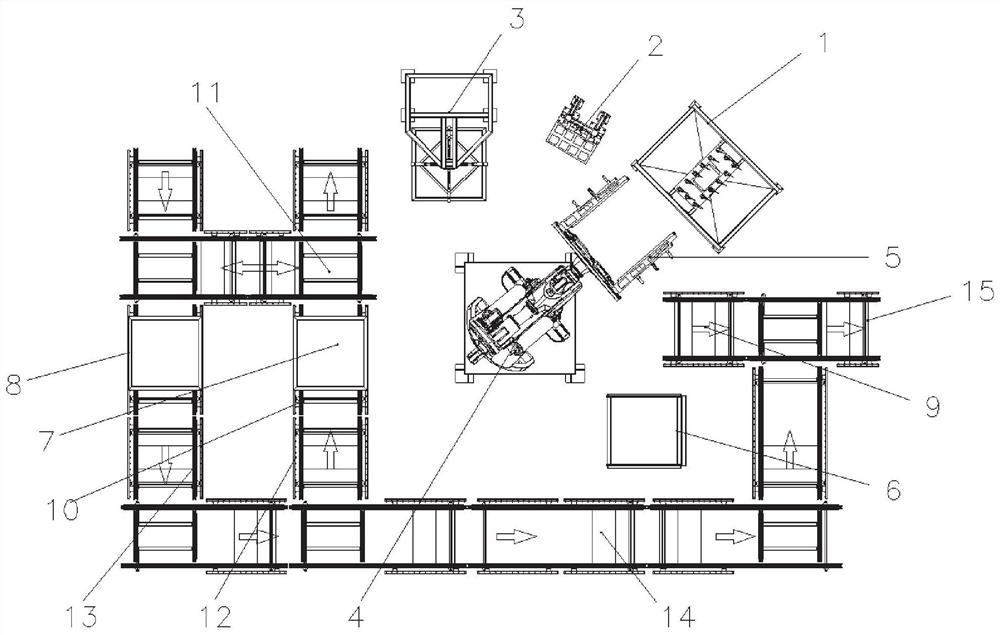

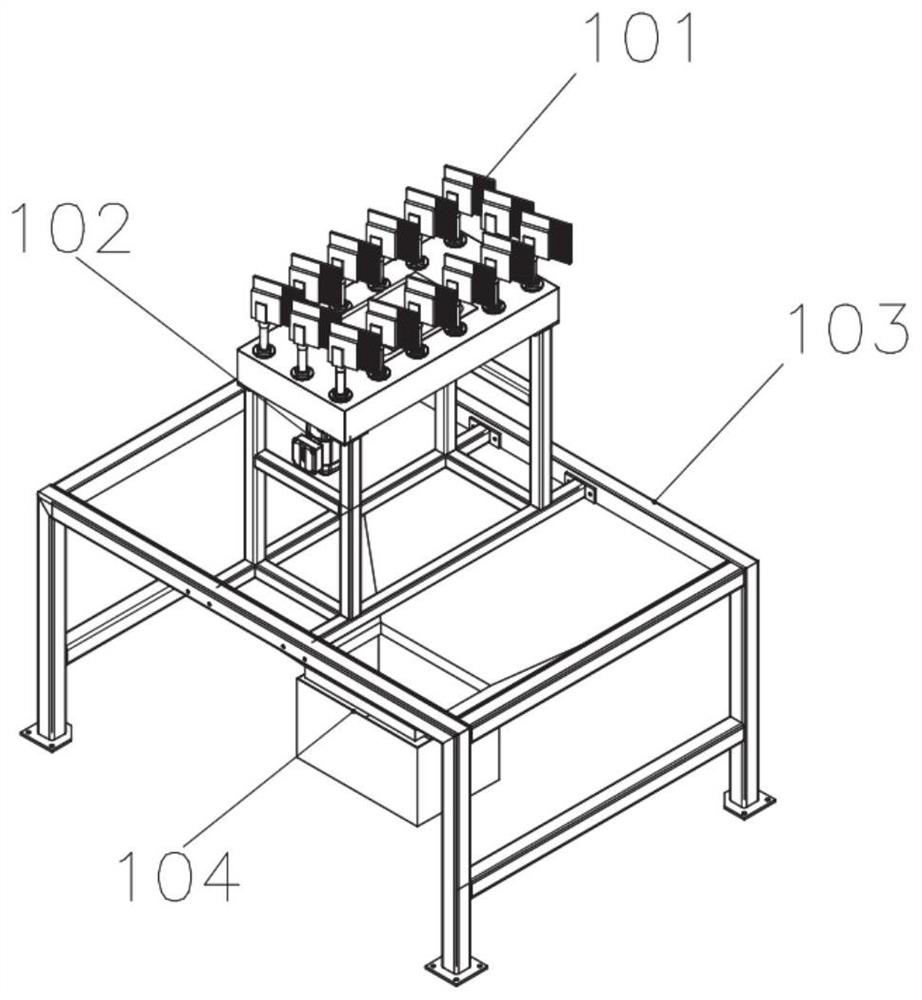

[0051] Such as Figure 1-Figure 10 As shown, the present embodiment provides a multifunctional shredded tobacco cleaning system, including a robot with end clamps and used for transferring shredded tobacco boxes, and a conveying line, a capping and removing device, a box lid storage rack, a cleaning device and an image recognition system are arranged around the robot Device; the conveying line is used to transport the shredded tobacco box, and the cover-removing device can clamp and fix the box cover of the shredded tobacco box, the box lid storage rack is used to store multiple box covers, and the cleaning device can extend into the To complete the cleaning of the inner cavity of the shredded tobacco box, the image recognition device can complete the photographing and image recognition of the inner cavity of the shredded tobacco box to judge whether the cleaning situation meets the requirements. The clamped shredded tobacco box includes a box cover and a box body.

[0052] S...

Embodiment 2

[0064] This embodiment provides a method for unstacking, cleaning and stacking empty shredded tobacco bins, comprising the following steps:

[0065] Step 1, when the stacked empty shredded tobacco boxes 7 are transported to the cleaning station 10, the robot body 4 drives the end gripper 5 to move from the waiting position to the cleaning station 10, and the clamping cylinder 501 drives the clamping arm 502 to embrace the empty box with a cover on the upper layer. Tobacco box, and move to the bottom of the cap removal device 3, remove the shredded tobacco box cover 601 for temporary storage;

[0066] Step 2, move the empty shredded tobacco box without cover to the top of the brush cleaning device 1 and turn it over, put the mouth of the box downwards on the brush cleaning device 1, and the robot 4 and the end clamp 5 of the robot drive the empty shredded tobacco box from the top Move down to complete the cleaning of half of the inner wall, then move the empty tobacco box horiz...

Embodiment 3

[0075] This embodiment provides a method for unstacking shredded tobacco boxes and caching the lids of shredded tobacco boxes, including the following steps:

[0076] Step 1, the stacked shredded tobacco boxes are delivered to the storage station.

[0077] Step 2, the end gripper moves to the buffering station and clamps the upper cut tobacco box, and moves it to the cleaning station to complete the destacking of the cut tobacco box.

[0078] Step 3, the end clamp moves to the buffer station and clamps the cut tobacco box cover, the end clamp moves to place the cover of the upper cut tobacco box in the box cover storage device for buffering, and then the upper cut tobacco box without a cover is transported to the setting station, by Forklift handling and follow-up operations.

[0079] Step 4, the end clamp moves to the cleaning station and clamps the lower tobacco box cover, moves it and places it in the box cover storage device buffer, and then transports the upper tobacco b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com