Casting mold of high alloyed alloy cast rod and preparation method thereof

A casting crystallizer and alloying technology, which is applied in the field of metal powder preparation, can solve the problems of not being able to simultaneously improve the solidification structure, uneven surface quality, and coarseness of high-alloyed alloy cast rods

Active Publication Date: 2022-06-03

LOUDI WENCHANG TECH

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

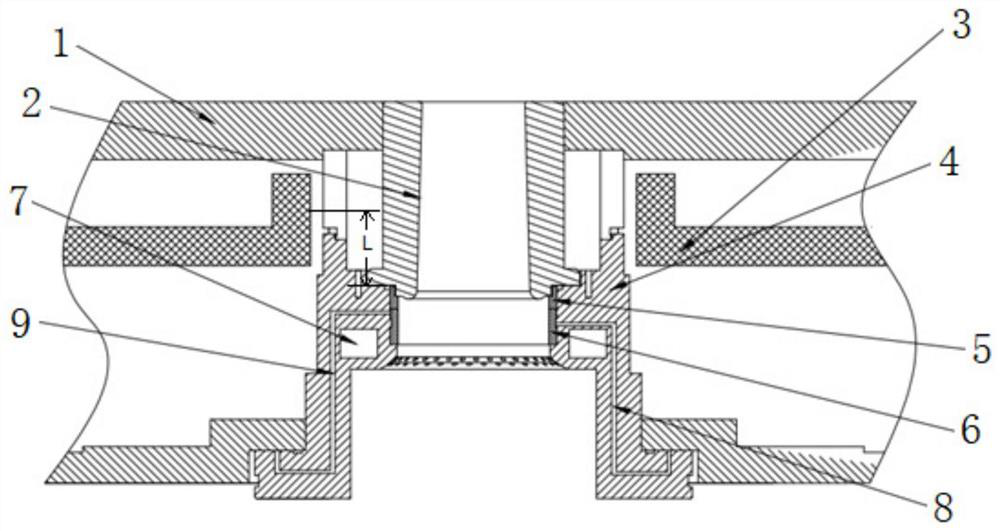

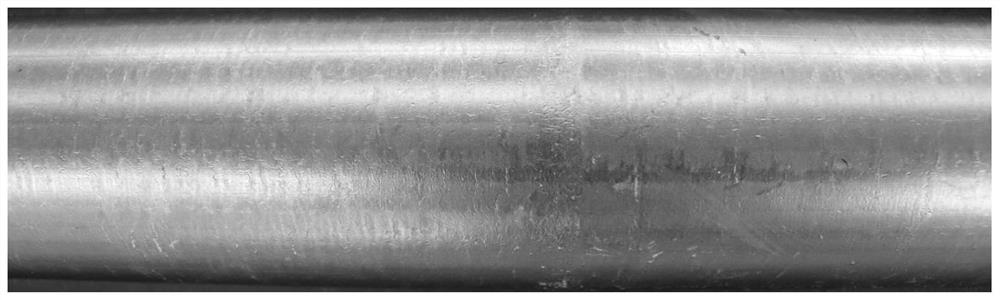

[0004] The main purpose of the present invention is to provide a casting crystallizer of high-alloyed alloy casting rod and its preparation method. The crystallizer is provided with a first graphite ring, and the first graphite ring is connected to the water supply system and the gas supply system respectively. A layer of vapor film is formed between the first graphite ring and the alloy casting rod, and the design of the electromagnetic coil structure is L-shaped, which can effectively improve the problems of coarse and uneven solidification structure and serious composition segregation of high-alloy alloy casting rods. The surface quality of cast rods is also significantly improved to solve the technical problems in the prior art that cannot simultaneously improve the solidification structure, unevenness and surface quality of high-alloyed alloy cast rods

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Login to View More

Abstract

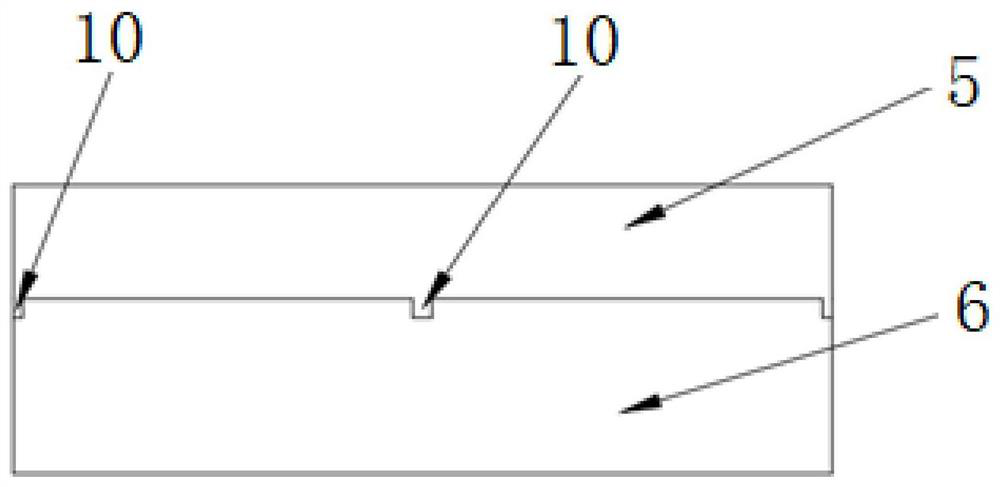

The invention provides a high-alloy alloy casting rod casting crystallizer and a preparation method thereof. The casting crystallizer includes a water tank, a draft tube, a crystallizer and an electromagnetic coil assembly, and the draft tube is embedded in the water tank; the crystallizer is set In the chamber of the water tank, the upper end of the crystallizer is sealed and connected with the lower end of the draft tube, and the lower end of the crystallizer is sealed and connected with the side wall at the opening of the water tank; at least a first graphite ring is provided in the crystallizer, and the first graphite The rings are respectively connected to the water supply and gas supply systems, and a layer of vapor film is formed between the first graphite ring and the alloy casting rod; the electromagnetic coil assembly includes at least a plurality of L-shaped electromagnetic coils, and the plurality of electromagnetic coils They are all set close to the top of the crystallizer. By setting the first graphite ring and designing the electromagnetic coil into an L-shaped structure, the crystallizer can effectively improve the problems of coarse and uneven solidification structure and serious component segregation of high-alloy alloy cast rods, and at the same time improve the surface quality of the cast rods. Significant improvement.

Description

Casting mold of high alloyed alloy cast rod and preparation method thereof technical field The present invention relates to metal powder preparation technical field, be specifically related to a kind of casting crystallization of high alloyed alloy cast rod device and method of making the same. Background technique In the casting process of high-alloying alloy bar, due to its high alloying element composition, when solidified Due to the sequential solidification and segregated crystallization characteristics of the alloy, it is inevitable that the solidification structure is coarse and non-uniform and the composition segregation Serious phenomenon will affect the performance of its cast rods; at the same time, due to the inevitable existence of alloys in the semi-continuous casting process The phenomenon of non-uniform melt temperature. In order to solve the above problems, the method of applying a physical external field is usually used to The solidification proc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22D11/055B22D11/115B22D11/117

CPCB22D11/055B22D11/115B22D11/117

Inventor 徐骏何敏李超张桢林

Owner LOUDI WENCHANG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com