Four-direction walking backpack type roller vehicle

A roller car and knapsack technology, which is applied in the field of four-way walking knapsack roller car, can solve problems such as cargo movement, damage to the backpack AGV, and dumping of the backpack AGV.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

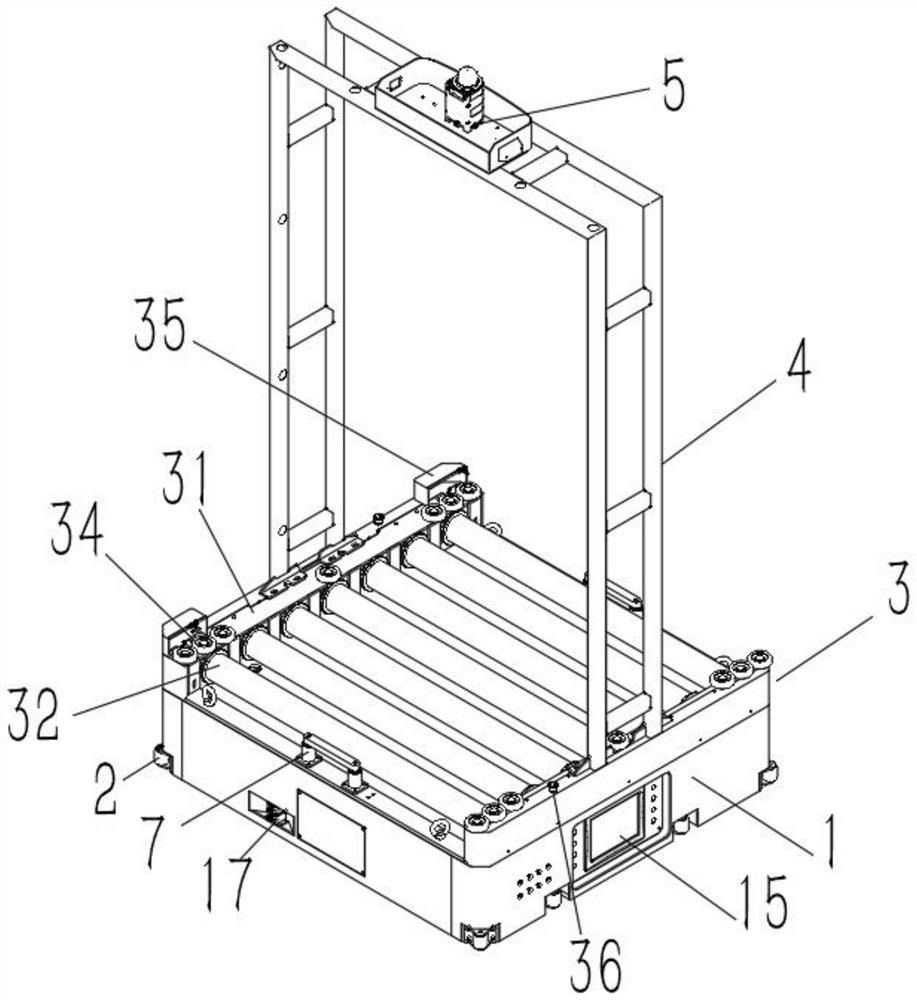

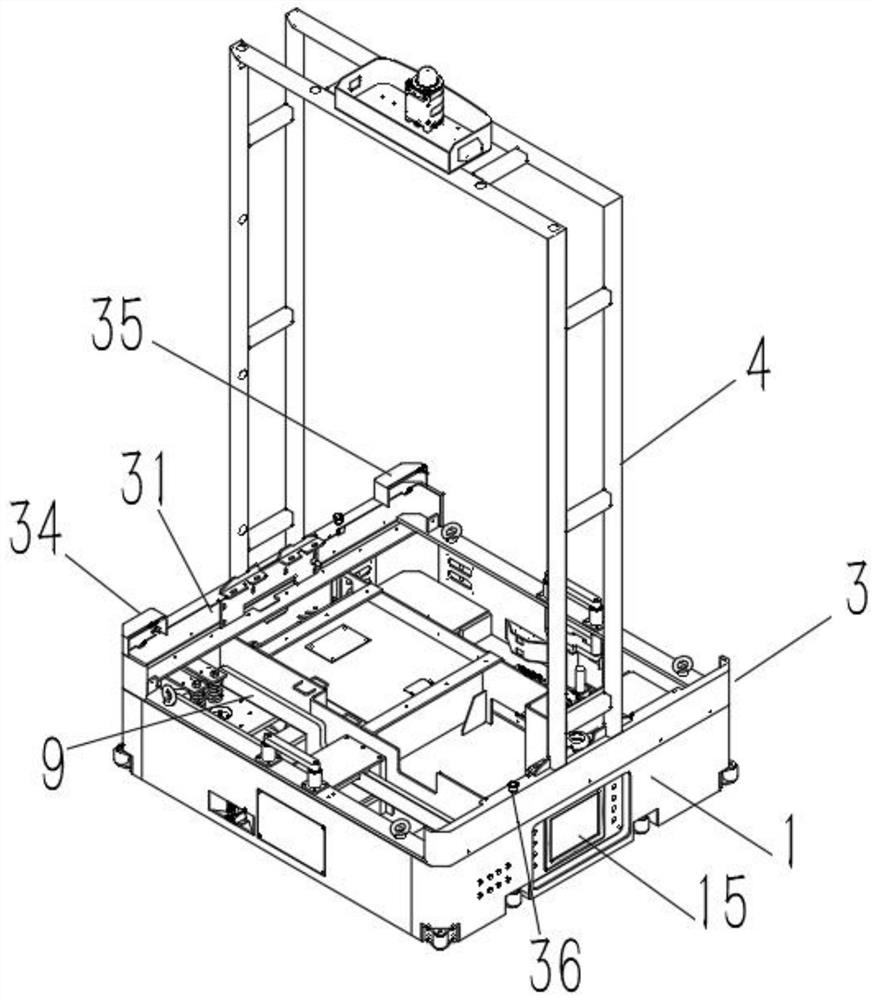

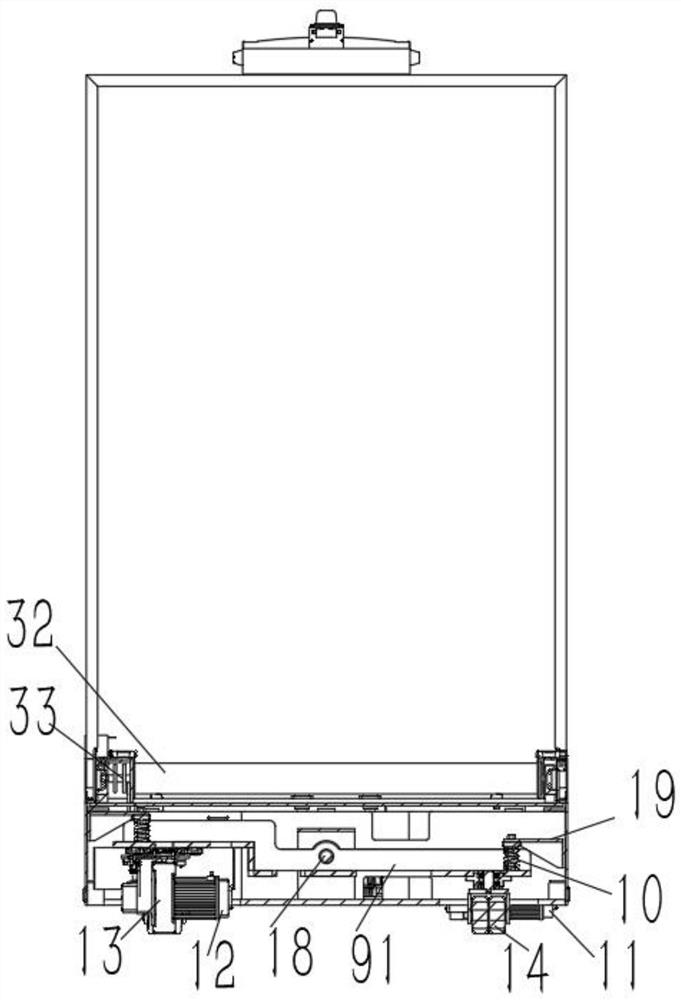

[0026]One of the specific embodiments of the present invention: see the accompanying drawings.

[0027]In the present embodiment, a four-way travel carrying roller vehicle includes a frame chassis 1, and the bottom circumference of each side of the frame chassis 1 is provided with a plurality of group guide wheels 2, the frame chassis 1 A roller assembly 3 is mounted, and the drum assembly 3 is provided with a mount 4, and the top of the mounting frame 4 is provided with a navigator 5, and a plurality of sets of roller assemblies 3 are fitted with the drum assembly 3. The positive inverting motor 6, the upper surface two opposite ends of the frame chassis 1 respectively provide a limiting device 7, and the two limit device 7 corresponds to the lifting pusher 8 provided in the frame chassis 1, respectively. The frame chassis 1 is fitted with a drive swing arm floating mechanism 9, and the driving swing arm floating mechanism 9 is connected to the frame chassis 1 by the spring mounting a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com