Material suction device

A technology of a suction device and a separation device, applied in the field of suction machines, can solve the problems of waste, inability to filter dust, and many impurities in the finished product.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

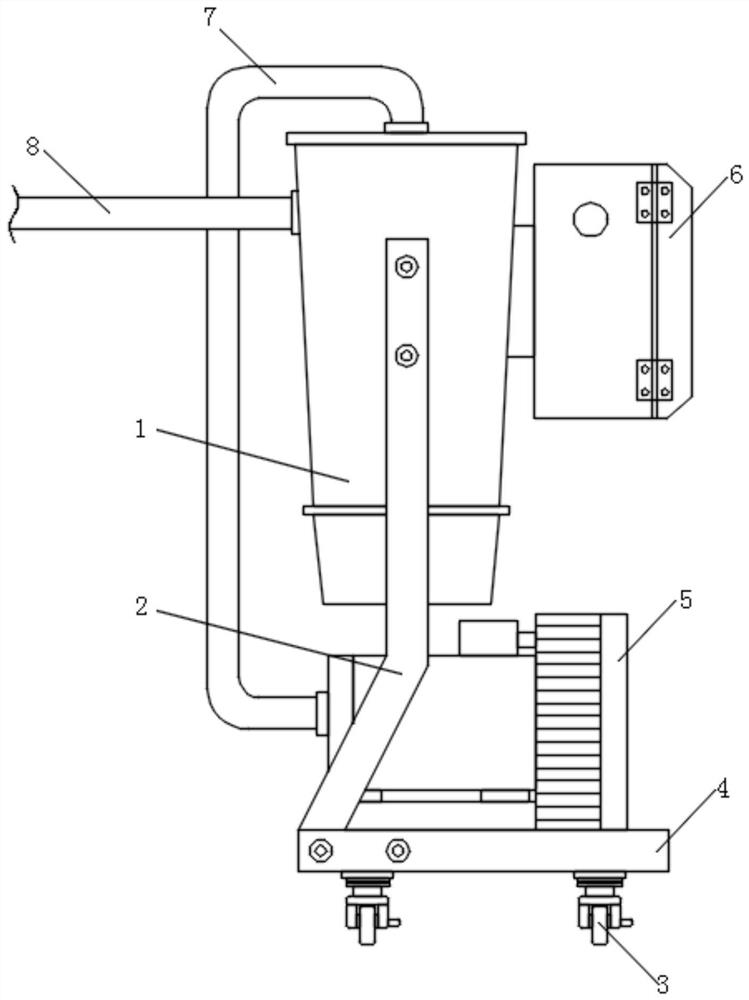

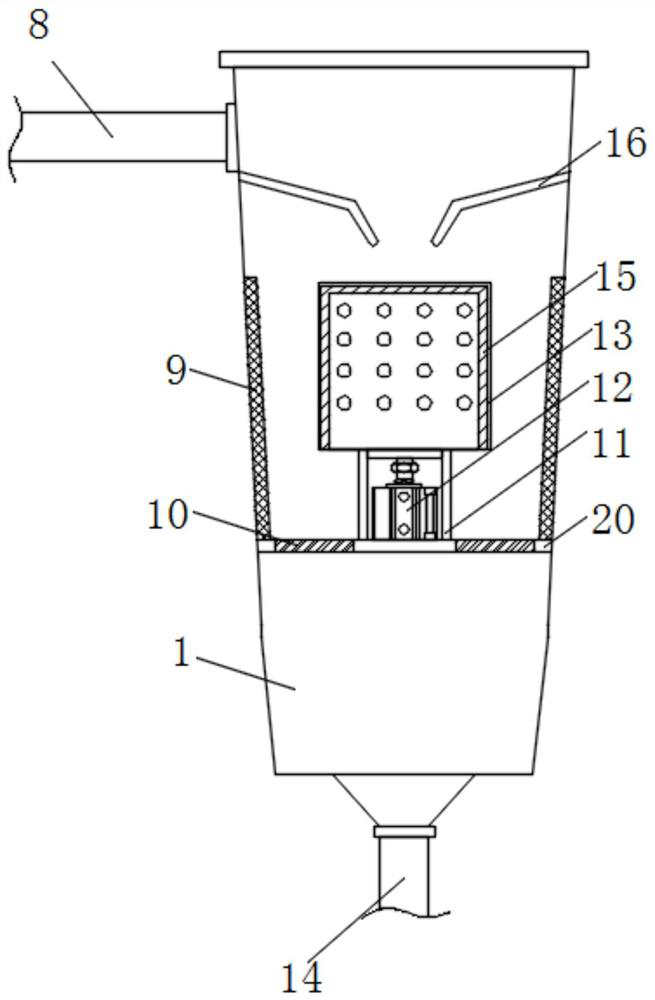

[0028] Now in conjunction with accompanying drawing and specific embodiment the present invention is further described, as Figure 1-3 As shown, the material suction device according to the embodiment of the present invention includes a silo 1, and a support frame 2 is installed on both sides of the silo 1, and a bottom plate 4 is installed at the bottom of the support frame 2, and a passage between the bottom plate 4 and the support frame 2 The screws are fixed, the top of the base plate 4 is installed with a vacuum pump 5, and one side of the vacuum pump 5 is equipped with a gas pipe 7, and the end of the gas pipe 7 far away from the vacuum pump 5 is connected with the feed bin 1, and the feed bin 1 side is installed with a feed pipe 8. A support plate 20 is installed inside the warehouse 1, and a separation device is installed on the top of the support plate 20. The separation device includes a support seat 11, a centrifugal motor 12 is installed inside the support seat 11, ...

Embodiment 2

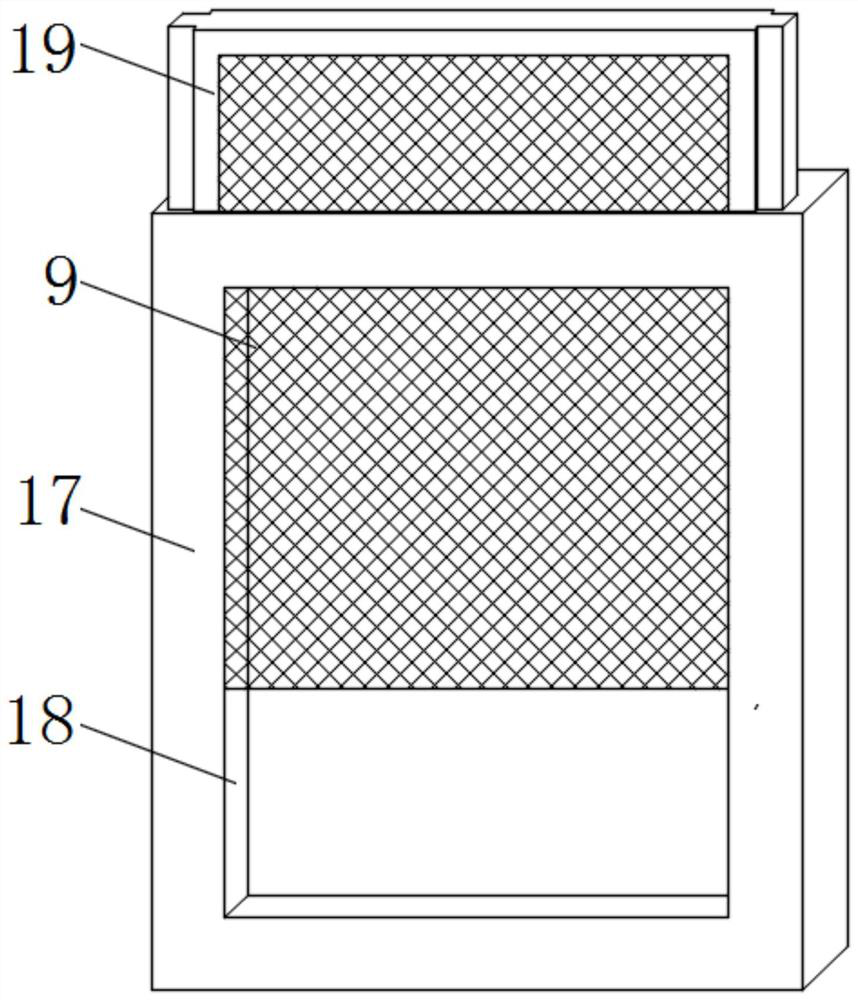

[0031] Such as Figure 1-3 As shown, for the suction device, the side of the feed bin 1 away from the feed pipe 8 is installed with a control box 6, and the control box 6 is connected with the feed bin 1 through an installation block; the bottom plate 4 is far away from the vacuum pump 5 A universal wheel 3 is installed at one end; a slant plate 16 is installed inside the bin 1, and the slant plate 16 is on the top of the separation device; adsorption mechanisms are installed on both sides of the separation device; the adsorption mechanism includes a fixed plate 17, and the middle part of the fixed plate 17 A groove 18 is provided, and a fixed block 19 is installed inside the groove 18, and the fixed block 19 is movably connected with the fixed plate 17, and an electrostatic dust collector 9 is installed inside the fixed block 19.

[0032] Through the above scheme of the present invention, the negative pressure airflow generated by the vacuum pump 5 enters the inside of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com