High-dryness sludge dewatering and filter pressing device, system and method

A technology for sludge dehydration and high dryness, applied in chemical instruments and methods, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problem of not being able to improve sewage filtration efficiency and high sludge Dryness dehydration, poor energy saving effect, interference data instability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

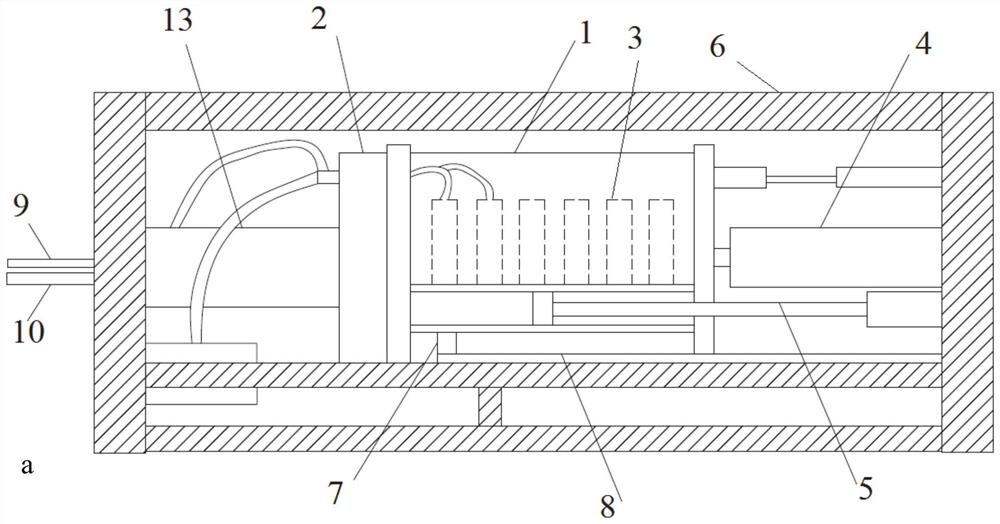

[0083] Such as image 3 As shown in Figure a and Figure B, it is a structural diagram of a high-dryness sludge dewatering filter press device, including an outer cylinder, a cylindrical cavity structure with one end open, and several filter plates inside; the front baffle, Located on the side opposite to the open end of the outer cylinder, the outer cylinder cooperates with the front baffle to form a sealed filter chamber; the main hydraulic cylinder is connected with several filter plates inside the outer cylinder; the auxiliary hydraulic cylinder is located on one side of the outer cylinder, Connect with the outer wall of the outer cylinder.

[0084] The front baffle is used to limit the position of the outer cylinder when it moves forward. When the outer cylinder advances to the position of the front baffle, the outer cylinder and the front baffle are combined into a closed space, and the system injects sewage into this space to realize the solid-liquid separation of sewage...

Embodiment 2

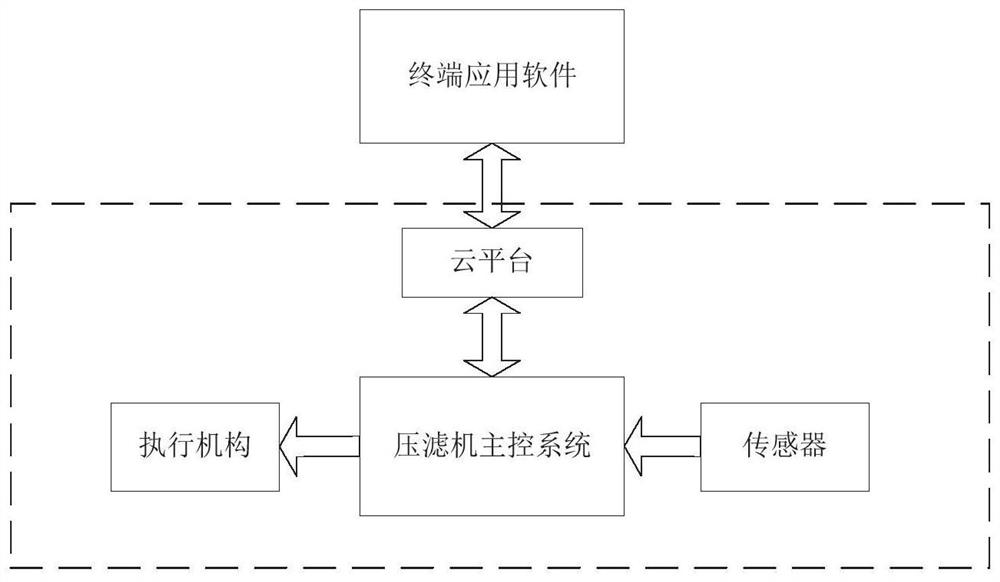

[0094] Such as figure 2 Shown is the running structure diagram, Figure 4 Shown is the control connection structure diagram of the dehydration filter press system, such as Figure 8 Shown is a structural diagram of the filter press system, including the filter press device of embodiment 1, information detection module, transmission module, and main control module, and the filter press device is connected with the information detection module, transmission module, and main control module in turn; the information detection module It is suitable for reading the information of flow data, position limit and pressure limit, and transmits the information to the transmission module; the transmission module is suitable for transmitting the information to the main control module; the main control module receives the information, processes the information, and obtains As a result, an order is issued.

[0095] After the sewage enters the filter press device, the information detection m...

Embodiment 3

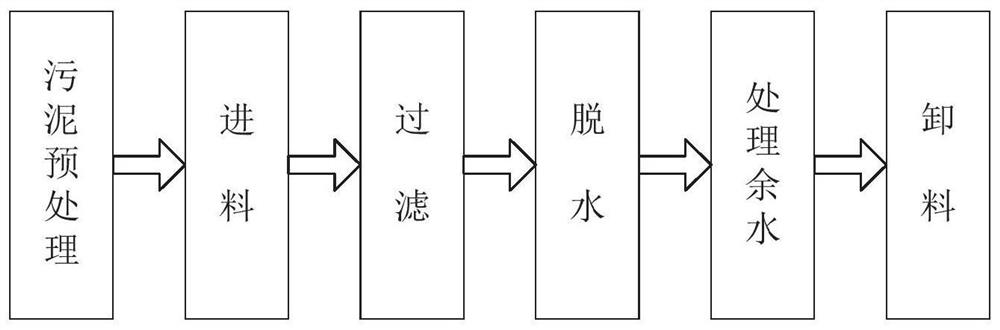

[0115] The method of high-dryness sludge dewatering and pressure filtration, the process is as follows Figure 7 shown. It specifically includes the process of feeding, filtering, dehydrating, removing residual water, and unloading.

[0116] Feeding process:

[0117] Such as Figure 9 As shown in the feeding work flow chart, it is judged whether the outer cylinder of the filter press is closely connected with the front baffle before the feeding action starts, and it is judged by detecting the pressure value of the auxiliary hydraulic cylinder. If the detected pressure is lower than the set lower limit, the system needs to control the outer cylinder to advance to make it higher than the set pressure upper limit, then open the inlet valve and outlet valve, and turn on the timer at the same time. At this time, the valve has been fully opened, the timer is turned off, and the feed pump is turned on at the same time, and sewage is started to be injected into the filter press at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com