High-viscosity and high-elasticity modified asphalt for steel bridge deck and preparation method thereof

A modified asphalt, viscoelastic technology, applied in building components, building insulation materials, buildings, etc., can solve the problems of easy segregation, high viscosity of asphalt, difficult mixing, paving and rolling, etc., to avoid concentrated gel Phenomenon, high temperature performance improvement, beneficial to production quality control and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

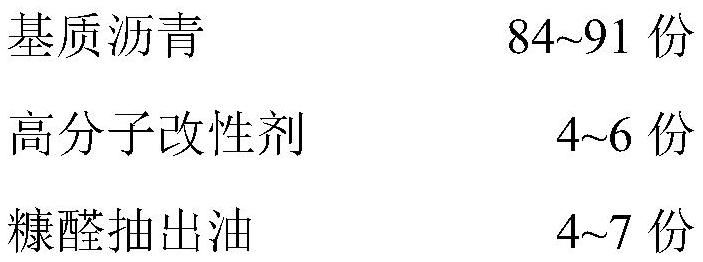

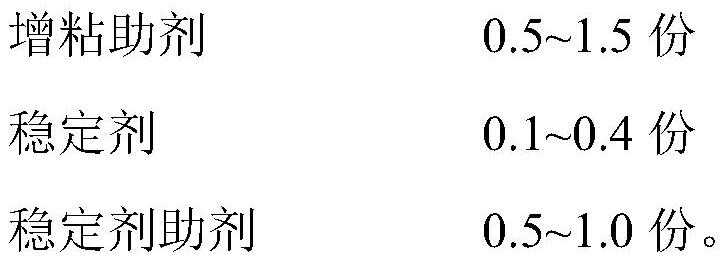

Method used

Image

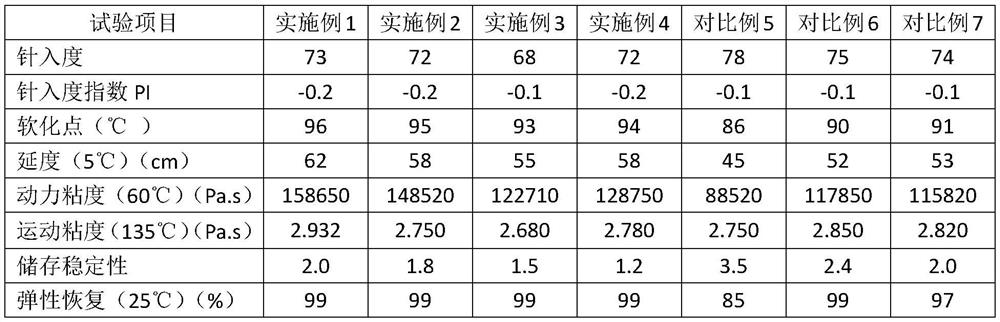

Examples

Embodiment 1

[0051] S1. Weigh 835g of Shuanglong 70# matrix asphalt, 40g of linear 791h modifier, 20g of SBR styrene-butadiene rubber, 15g of ethylene bisstearic acid amide, 70g of furfural extraction oil, 4g of sulfur stabilizer, and 10g of NNO diffusion powder.

[0052] S2. After heating Ssangyong 70# base asphalt at 130℃~140℃ to a fluid state, put it into an oil bath with a preset temperature of 165℃ and stir for 0.5h to preheat, then add linear 791h modifier and SBR butyl For styrene rubber, use a shearing machine to cut at 4000r / min for 0.5h;

[0053] S3. After the shearing is completed, add furfural at 175°C±5°C to extract the oil, and then stir for 1 hour;

[0054] S4. After stirring and developing, add ethylene bis stearic acid amide, and stir and develop at 175°C±5°C for 2 hours;

[0055] S5. Slowly add the sulfur stabilizer after the growth is complete. The adding time should be between 0.5 and 1.5 hours. After the addition is completed, stir and mix at 175°C±5°C for 0.5h;

[0...

Embodiment 2

[0059] S1. Weigh 880g of Shuanglong 70# base asphalt, 50g of linear 791h modifier, 15g of ethylene bis stearic acid amide, 50g of furfural extract oil, 3g of sulfur stabilizer, and 7g of NNO diffusing powder.

[0060] S2. After heating Ssangyong 70# base asphalt at 130℃~140℃ to a fluid state, put it into an oil bath with a preset temperature of 165℃ and stir for 0.5h to preheat, then add linear 791h modifier, use shears The cutting machine cuts at 4000r / min for 0.5h;

[0061] S3. After the shearing is completed, add furfural at 175°C±5°C to extract the oil, and then stir for 1 hour;

[0062] S4. After stirring and developing, add ethylene bis stearic acid amide, and stir and develop at 175°C±5°C for 2 hours;

[0063] S5. Slowly add the sulfur stabilizer of corresponding quality after the development is complete. The adding time should be between 0.5 and 1.5 hours. After the addition is completed, stir and mix at 175°C±5°C for 0.5h;

[0064] S6. Add NNO diffusing powder, stir...

Embodiment 3

[0067] S1. Weigh 920g of Shuanglong 70# base asphalt, 40g of linear 791h modifier, 5g of ethylene bis stearic acid amide, 40g of furfural extract oil, 1g of sulfur stabilizer, and 5g of NNO diffusing powder.

[0068] S2. After heating Ssangyong 70# base asphalt at 130℃~140℃ to a fluid state, put it into an oil bath with a preset temperature of 165℃ and stir for 0.5h to preheat, then add linear 791h modifier, use shears The cutting machine cuts at 4000r / min for 0.5h;

[0069] S3. After the shearing is completed, add furfural at 175°C±5°C to extract the oil, and then stir for 1 hour;

[0070] S4. After stirring and developing, add ethylene bis stearic acid amide, and stir and develop at 175°C±5°C for 2 hours;

[0071] S5. Slowly add the sulfur stabilizer of corresponding quality after the development is complete. The adding time should be between 0.5 and 1.5 hours. After the addition is completed, stir and mix at 175°C±5°C for 0.5h;

[0072] S6. Add NNO diffusing powder, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com