High-pier-side cast-in-place bracket

A high-pier, cast-in-place technology, applied in the erection/assembly of bridges, bridge parts, bridges, etc., can solve the problems of large impact on the appearance quality of concrete, large impact on the construction of the pier body, and adverse effects on concrete.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

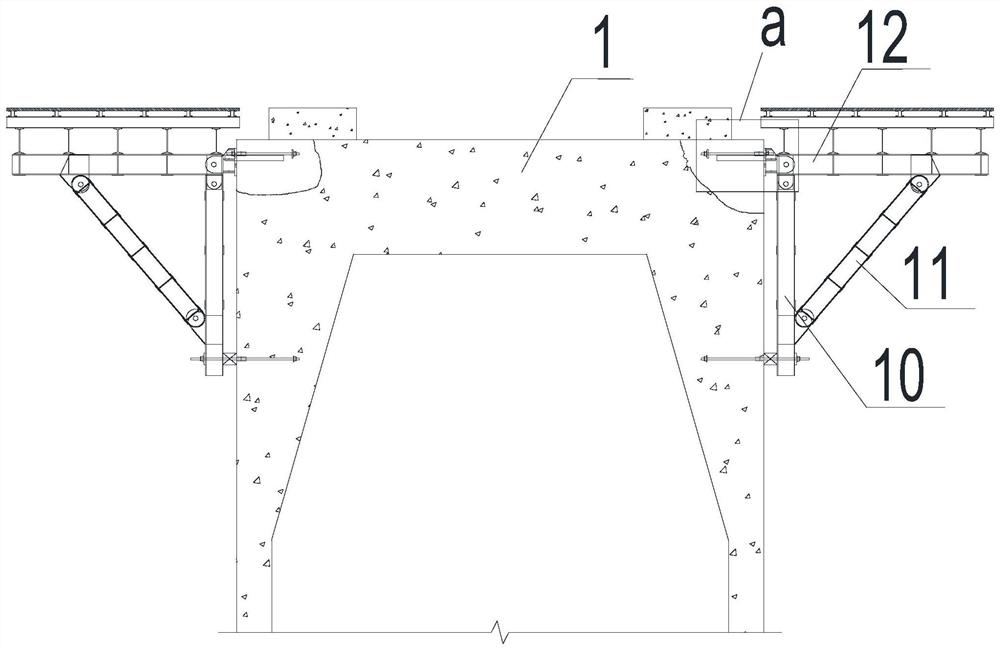

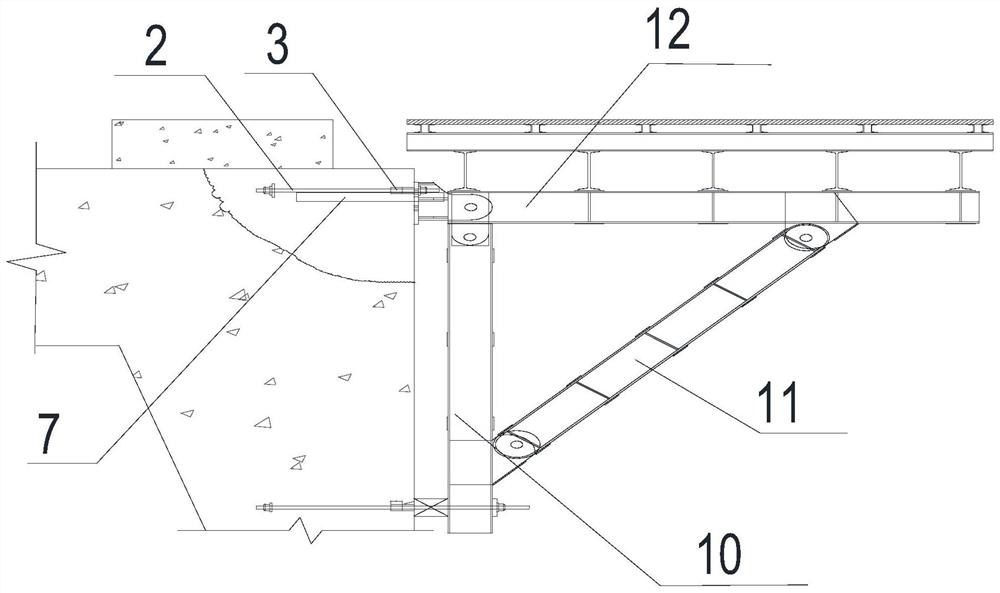

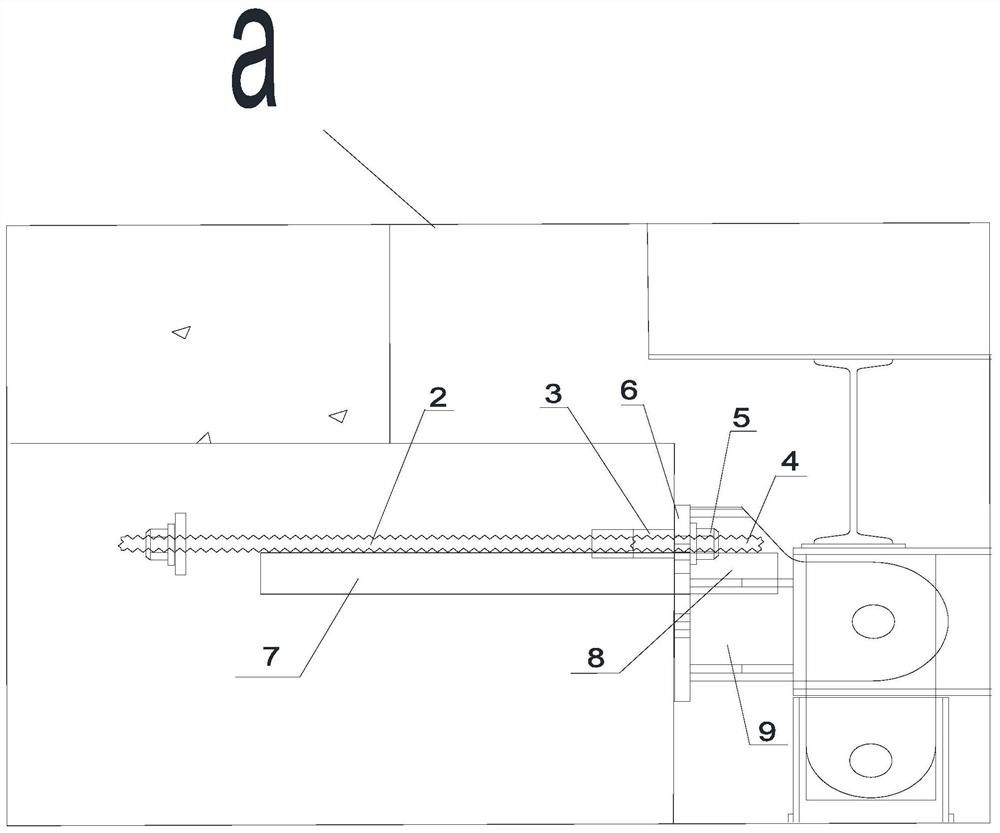

[0040] Example: such as Figure 1 to Figure 7 As shown, a cast-in-place bracket next to a high pier includes support structures respectively arranged on both sides of the pier 1, the support structure is used to support the box girder, and also includes a pre-embedded unit, a backing plate 6 and an accessory hanger 9 ;

[0041] The pre-embedded unit includes a finished-rolled rebar 2, a rebar connector 3 and an anchor bar 4, and the tops of both sides of the pier 1 are provided with a finished-rolled rebar 2 and a rebar connector 3, and the finished-rolled rebar 2 and the rebar connector 3 are located inside the pier 1, the end of the finished rolled rebar 2 away from the center of the pier 1 is connected to one end of the rebar connector 3, and one end of the anchor rib 4 is inserted into the other end of the rebar connector 3 , and connected with the finish-rolled rebar 2, the other end of the anchor bar 4 is located outside the pier 1, and the pre-embedded unit is placed h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com