Construction method of formwork support protection device

A technology of protective device and formwork, applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and on-site preparation of building components, can solve the problem of insufficient support strength, increase the risk of water seepage, Problems such as cold seams on the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

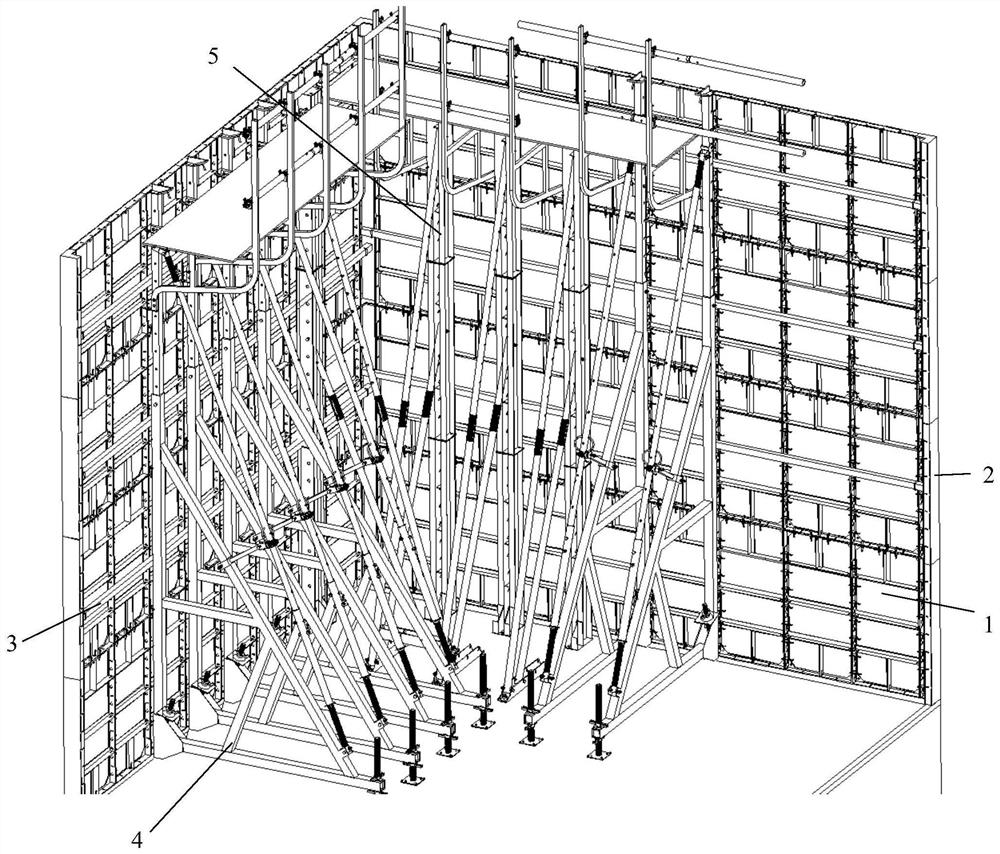

[0045] see Figure 1 to Figure 8 , the invention provides a construction method for a formwork supporting protective device, comprising a formwork wall composed of several interconnected steel frame wooden formworks 1, a corner formwork 2 connected to the corner of the formwork wall, and fixed on one side of the formwork wall The back square steel support 3 and the triangular support frame 4 arranged on the inside of the formwork wall, the corners connected by the adjacent formwork walls are fixedly connected by the corner support 5;

[0046] The back square steel support 3 and the steel frame wooden formwork 1 are connected by a fastener 301, and the tripod support frame 4 and the corner support 5 are all provided with a working pedal support 6.

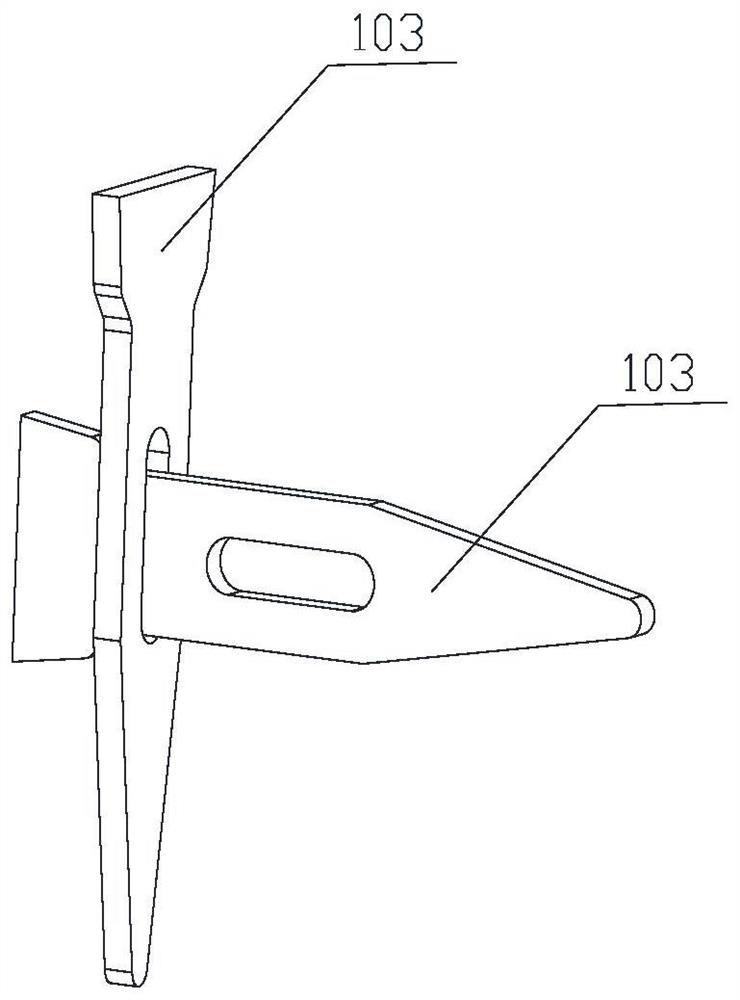

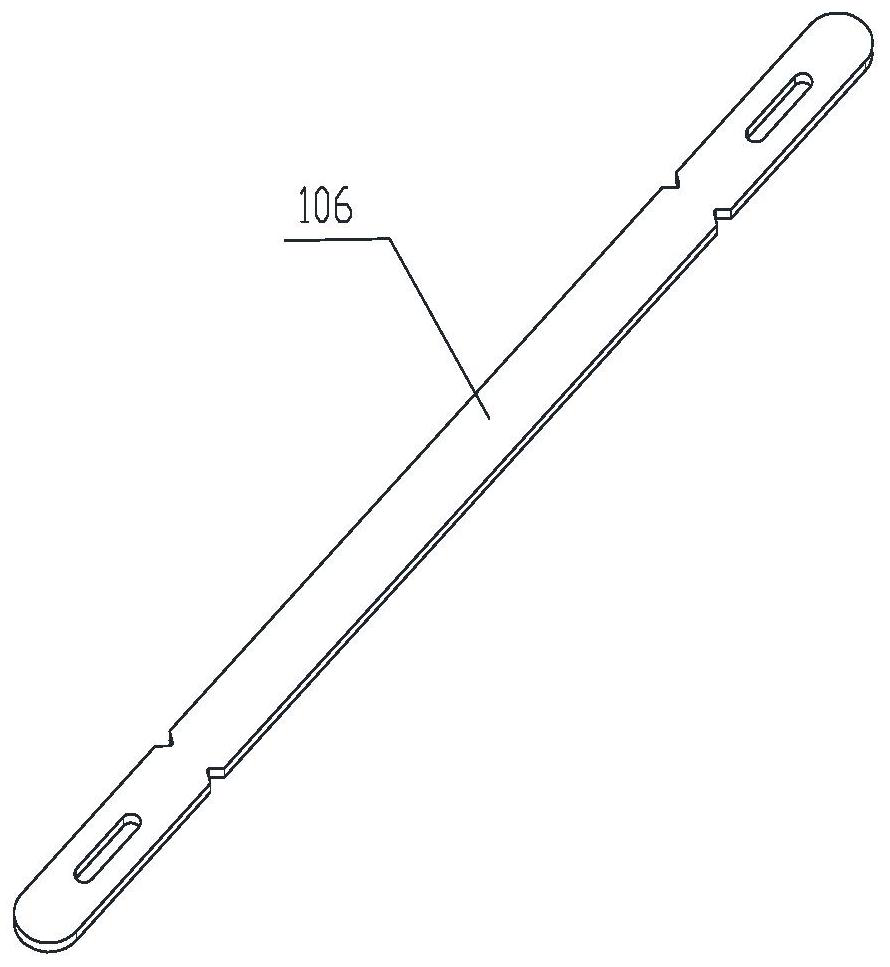

[0047] The steel frame wooden formwork 1 is composed of an outer frame 101 and a wooden board 102 embedded in the outer frame 101, and the four corners of the outer frame 101 and the wooden board 102 are fixedly connected by cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com