Speed change mechanism for high-speed and low-speed two-gear transmission

A speed change mechanism, low-speed technology, applied in the direction of transmission, gear transmission, mechanical equipment, etc., can solve the problems of inappropriate, low maintainability, low separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below by way of examples. Through these descriptions, the features and advantages of the present invention will become more apparent. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

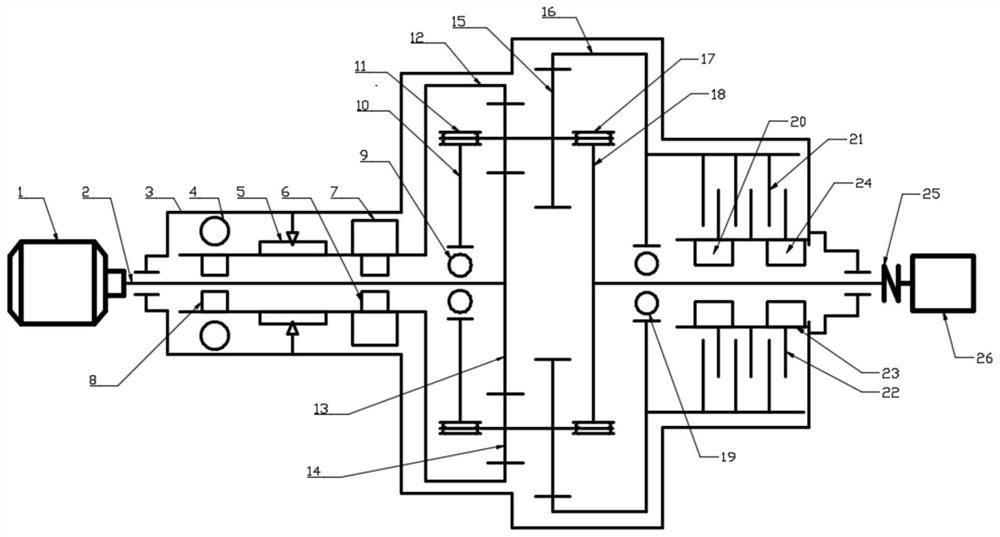

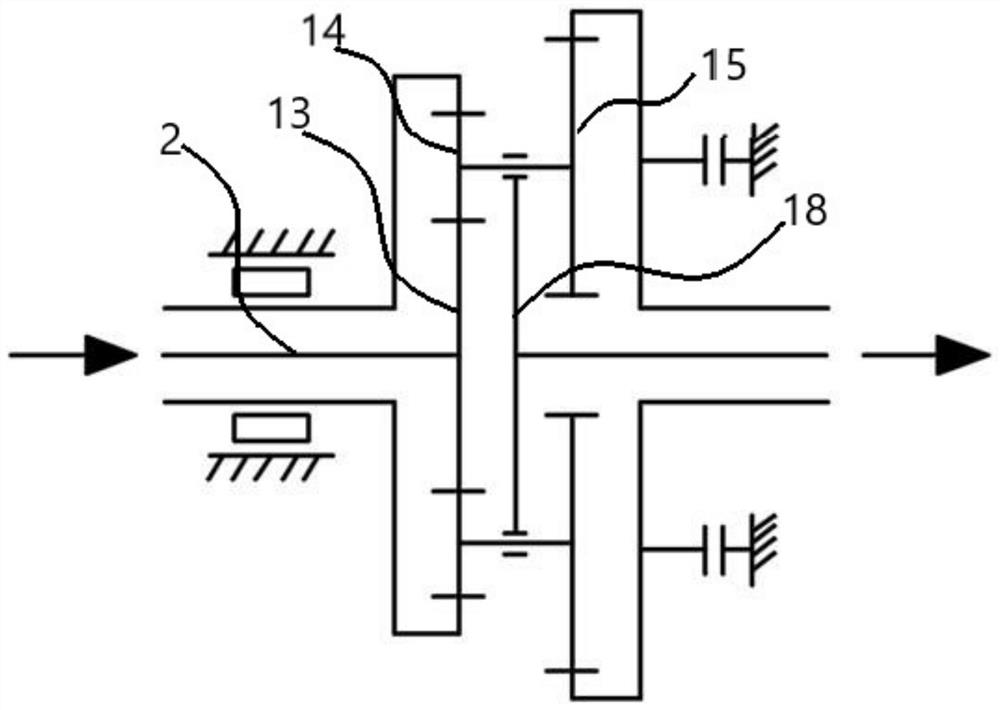

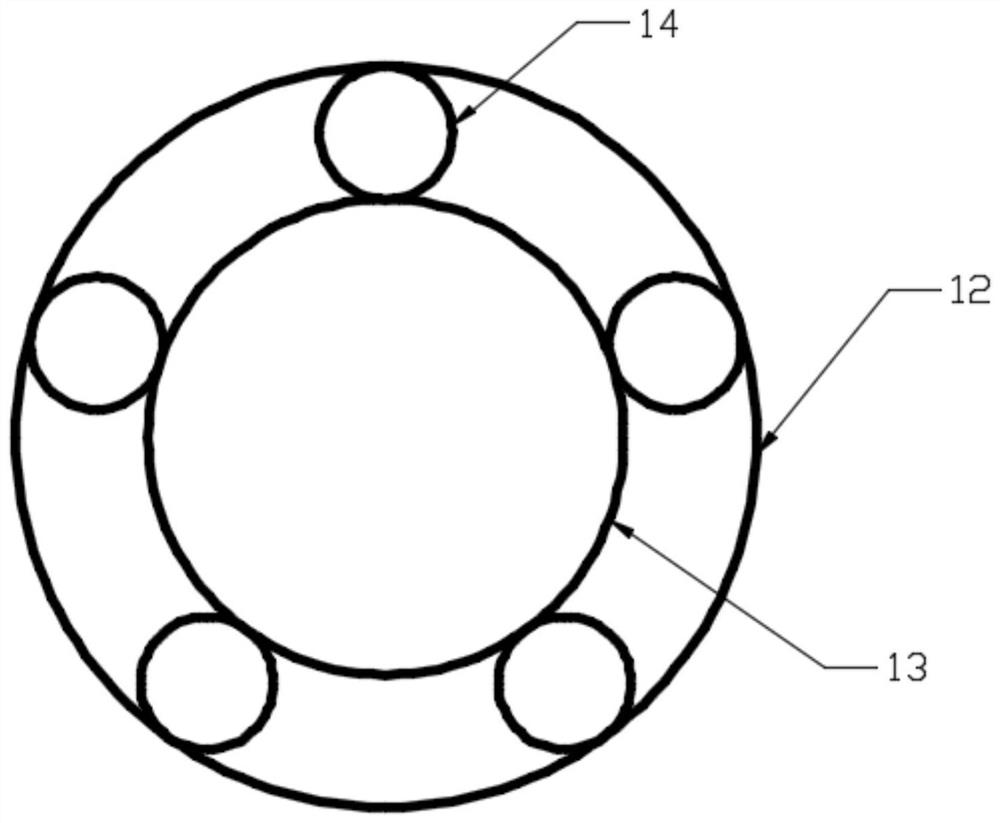

[0026] Such as Figure 1-5 As shown, the transmission mechanism for high and low speed two-speed transmission in this embodiment includes: input motor 1, input shaft 2, casing 3, primary planetary gear train, secondary planetary gear train, spline shaft 23, A shaft coupling 25 and a load working machine 26; the primary planetary gear train includes a primary planet carrier 10, a primary needle roller and cage assembly 11, a primary ring gear 12, a primary sun gear 13 and a primary planetary gear The first-stage planet carrier 10 is rotatably assembled with the input shaft 2 through the support bearing 9 at the input end, and the shaft section of the first-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com