Carbon steel workbench depth and aperture detection device

A detection device and worktable technology, applied in the field of mechanical workpiece processing, can solve the problems of inaccurate measurement of deep and shallow apertures of workpieces and difficulty in measurement of apertures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

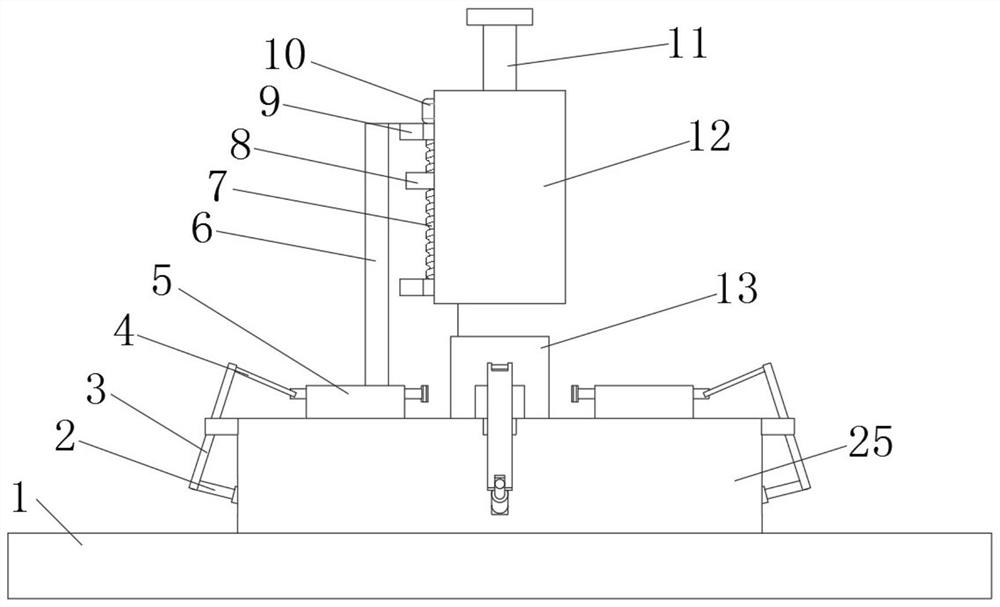

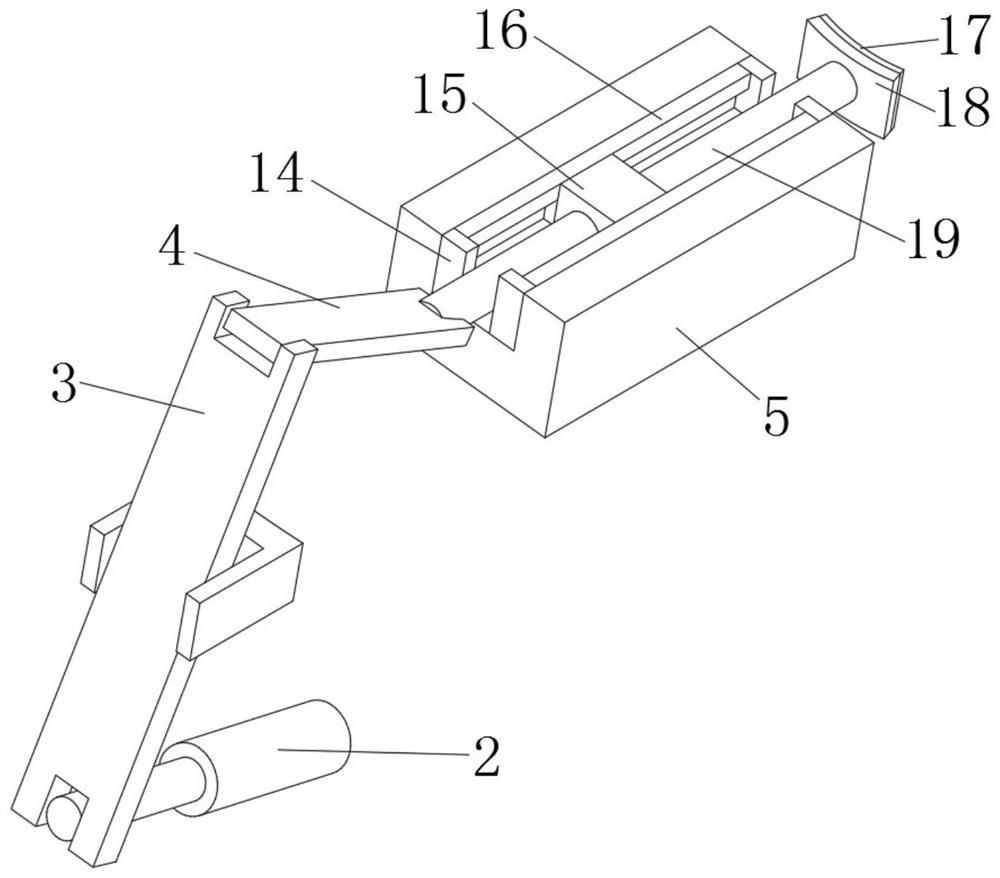

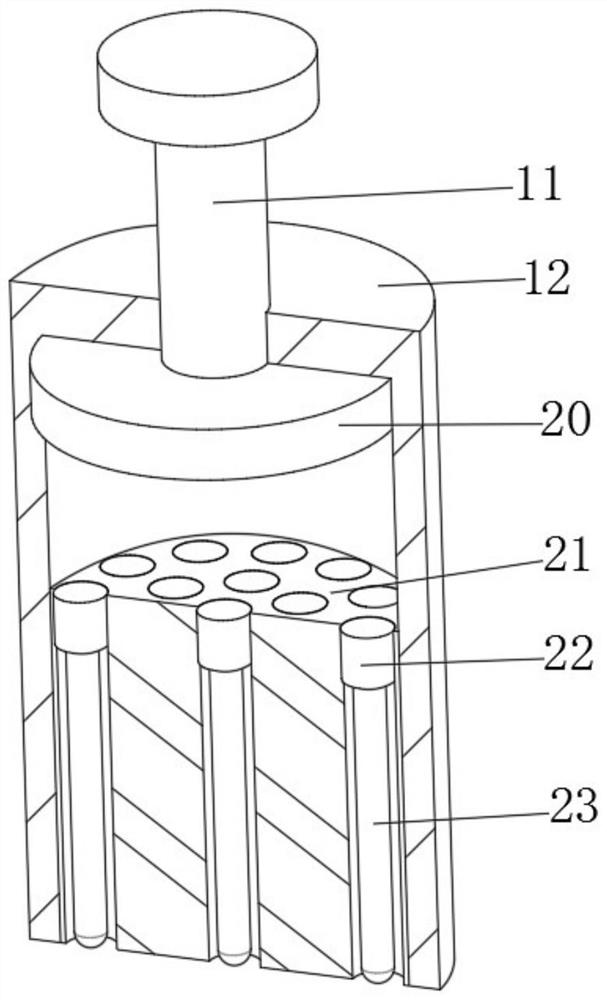

[0036] refer to Figure 1-6, a carbon steel workbench deep and shallow aperture detection device, comprising a base plate 1, a measuring cylinder 12, the top outer wall of the base plate 1 is fixed with a measuring platform 25 by screws, and the top of the measuring platform 25 is provided with a clamping mechanism, the top of the measuring platform 25 The workpiece body 13 is placed on the outer wall, and the clamping mechanism fixes the workpiece body 13 tightly. The first mounting block 21 is fixedly installed inside the measuring cylinder 12, and the top outer wall of the first mounting block 21 is provided with uniformly distributed through holes. The inner wall of the hole is movably connected with a third first mounting block 22, and the bottom outer wall of the third first mounting block 22 is fixedly connected with a movable rod 23, and the inner wall of the measuring cylinder 12 is slidably connected with a piston 20, and the top outer wall of the piston 20 is fixed. ...

Embodiment 2

[0047] refer to Figure 7 , a deep and shallow aperture detection device for a carbon steel workbench. Compared with Embodiment 1, this embodiment also includes a gasket 24 arranged on the bottom outer wall of the measuring cylinder 12, and the gasket 24 prevents the measuring cylinder 12 from colliding strongly with the workpiece body 13 to protect the workpiece. Body 13 and measuring cylinder 12 .

[0048] Working principle: through the set gasket 24, when the measuring cylinder 12 moves downward, the bottom of the measuring cylinder 12 contacts the top of the workpiece body 13, and the gasket 24 buffers the impact force between the measuring cylinder 12 and the workpiece body 13, protecting the workpiece body 13 The structure is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com