Crushing device for food detection based on chromatographic analysis method

A food detection and crushing device technology, applied in the direction of measuring device, analysis material, material separation, etc., can solve the problems of general crushing effect, single operation mode of crushing mechanism, influence of detection result accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

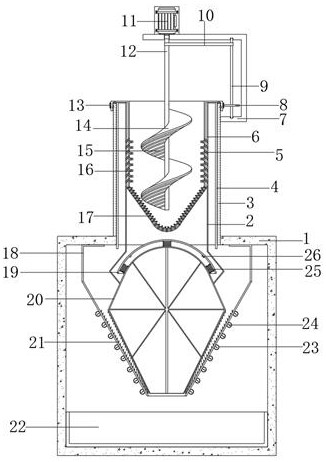

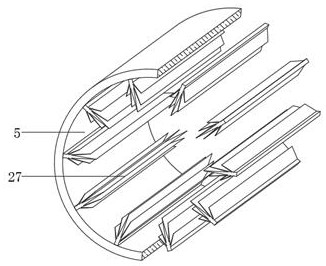

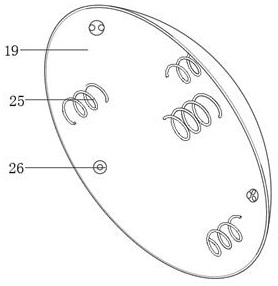

[0029] refer to Figure 1-4 , a crushing device for food detection based on chromatographic analysis, including a main body 1, a top end cylinder 3 is fixedly installed on the top of the main body 1, and a double-layer rotating cylinder 6 is connected to the top of the top end cylinder 3 through bearing rotation, and the double-layer rotating cylinder The bottom end of the cylinder 6 is welded with a bottom pocket 17, and the double-layer rotating cylinder 6 and the bottom pocket 17 are all provided with equidistantly distributed feed openings, and the inner wall of the feed opening is welded with a discharge inclined pipe 5, and the discharge inclined pipe 5 The inner wall is welded with pipe wall cutter teeth 27 distributed equidistantly, and the outer wall of one side of the top end cylinder 3 is welded with a bracket 7, and the top of the bracket 7 is fixed with a rotating motor 11 by bolts, and the output shaft of the rotating motor 11 is connected with a The main rod 12,...

Embodiment 2

[0039] refer to Figure 5 , a kind of broken device for food detection based on chromatographic analysis, compared with Embodiment 1, this embodiment also includes edge knives 28 that are welded with equidistant distribution at the edge of the spiral pusher piece 14 .

[0040] In the present invention, the interlaced parts of the main rod 12 and the spiral push piece 14 are welded with secondary blades 29 that are equally spaced and spirally distributed. 29, which can effectively improve the scope of action of the spiral pusher piece 14 and the performance of crushing materials; and the top of the secondary edge 29 is welded with thorns 30 distributed equidistantly; the thorns 30 arranged on the secondary edge 29 can further improve the scrap effect.

[0041] When the present invention is used: the edge knife 28 arranged on the spiral pusher 14 and the auxiliary edge 29 arranged on the main rod 12 can effectively improve the range of action of the spiral pusher 14 and the cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com