Laser welding control equipment integrating bus stepping drive and control

A technology of laser welding and control equipment, applied in digital control, program control, electrical program control, etc., which can solve the problems of multiple lines, inconvenient installation and disassembly, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

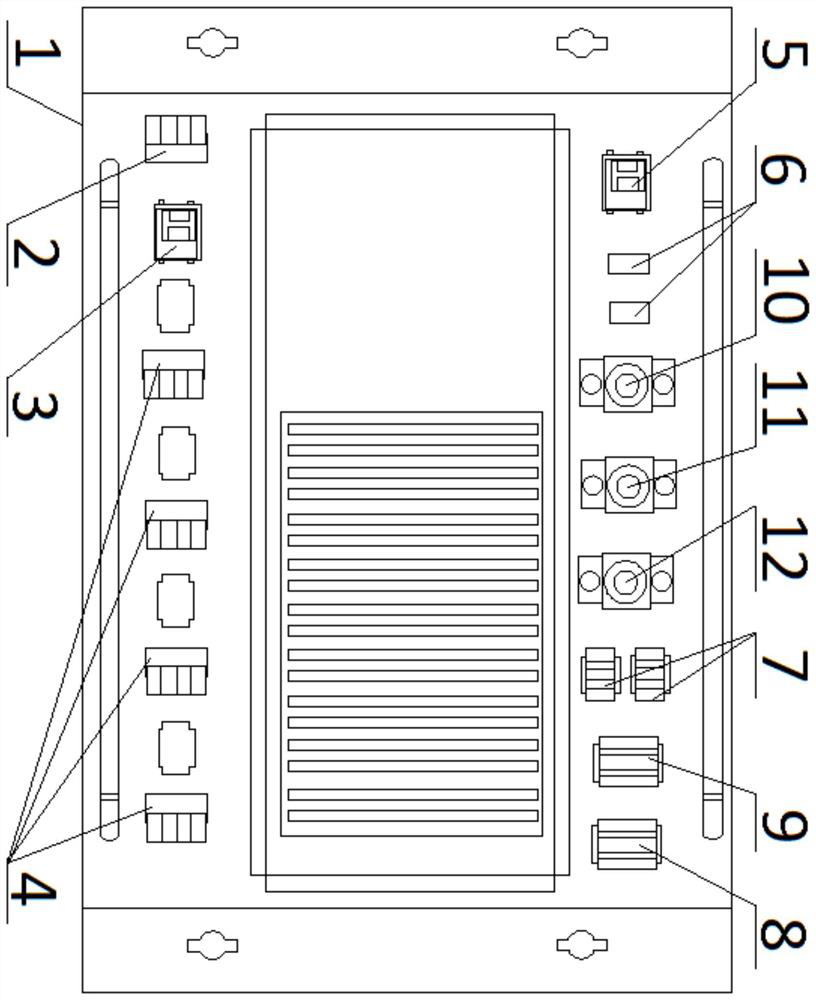

[0017] figure 1 It schematically shows the structure of the wiring surface of a laser welding control device integrated with bus stepping drive and control according to an embodiment of the present invention. Such as figure 1 As shown, the laser welding control equipment includes a shell 1, and a driver and a controller are installed inside the shell 1, and the EtherCAT bus communication protocol is adopted between the driver and the controller, and a laser control module is also arranged on the controller And IO input and output modules.

[0018] Because in laser welding technology, the driver and controller can basically be connected with other equipment, therefore, when the driver and controller are integrated together, other equipment can be directly connected with the laser welding control equipment , to achieve laser welding work together.

[0019] Among them, the equipment directly connected with the laser welding control equipment mainly includes power supply, vario...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com