Numerical simulation method for fluid-solid coupling in hydraulic fracturing process of single-fracture rock

A hydraulic fracturing and numerical simulation technology, applied in CAD numerical modeling, electrical digital data processing, instruments, etc., can solve the problems of difficulty in revealing microscopic mechanisms, high cost, and long hydraulic fracturing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] A numerical simulation method for fluid-solid coupling in a single fracture rock hydraulic fracturing process, comprising the following steps:

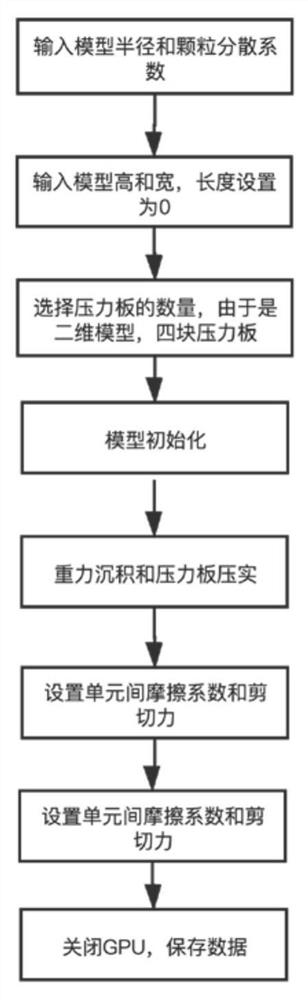

[0035] Step S1, such as figure 1 Shown is the flow chart of building a two-dimensional model box for hydraulic fracturing, creating a Box modeler object B, where sampleW represents the width of the model box, sampleL represents the length of the model box, and sampleH represents the height of the model box; set sampleL=0, the The model is set to be a 2D model.

[0036] Step S2, setting the initial sample unit average radius and boundary unit radius; wherein the ratio of the sample maximum particle size to the minimum particle size is 1+distriRate, and distriRate represents the dispersion coefficient of the sample particle unit radius.

[0037] According to the set width, height, and length set to 0, a 3D model box of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com