Flexible packaging substrate contour, line width and line distance defect detection method, medium and equipment

A flexible packaging and contour detection technology, which is applied in the application field of image processing technology and can solve problems such as low efficiency of point-by-point traversal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

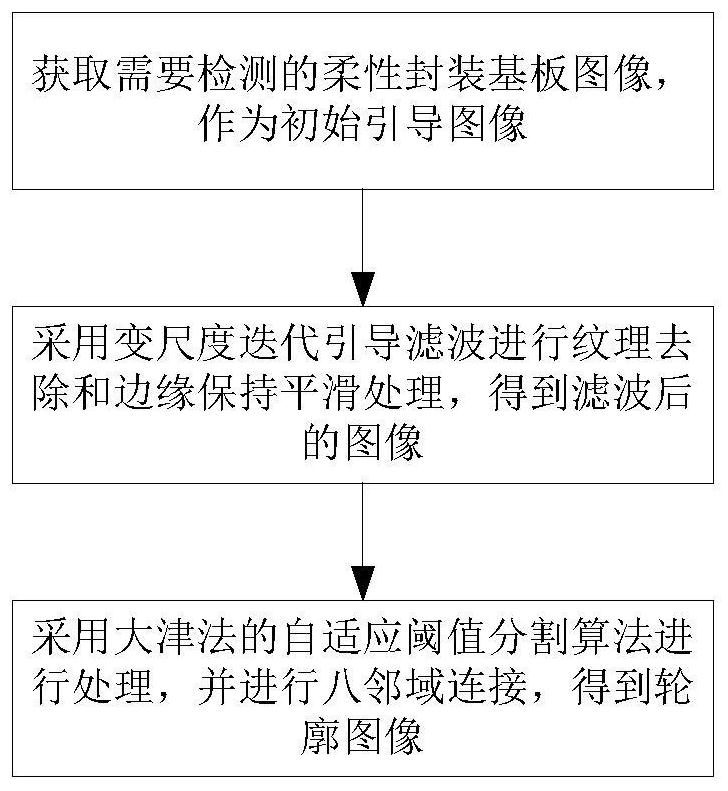

[0088] This embodiment discloses a method for detecting the outline of a flexible packaging substrate, which can be executed on smart devices such as computers, such as figure 1 , the steps of the method include:

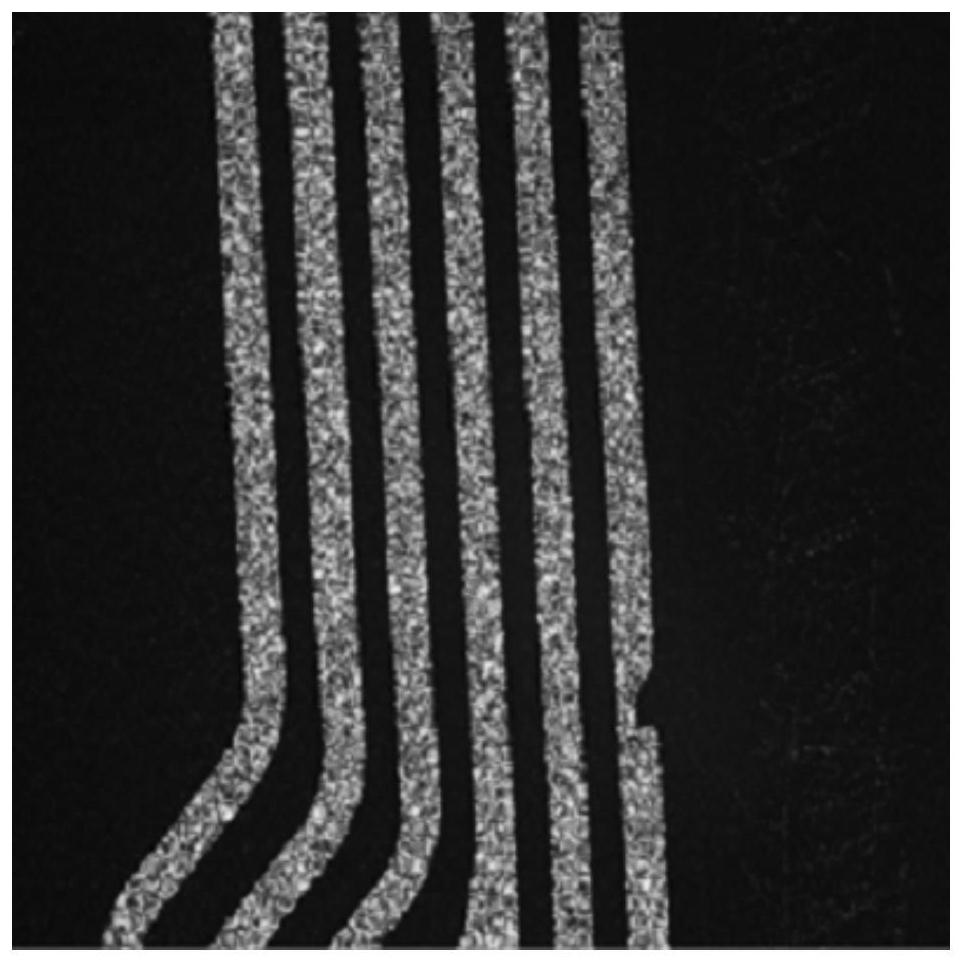

[0089] Step S1. Obtain the image O of the flexible packaging substrate to be detected, such as image 3 As shown in , it is used as the initial guide image; for the flexible packaging substrate image O, the variable-scale iterative guide filter is used for texture removal and edge smoothing, and the filtered image Q is obtained, as follows:

[0090] Step S11, firstly adjust the size of the selected flexible packaging substrate image O to N×N pixels, and determine the initial value r of the scale space parameter 0 :

[0091]

[0092] Among them, r 0 is the initial value of the scale space parameter, T is the total number of iterations, and N is the side length of the original image O;

[0093] Step S12, in linear form r=k(t-1)+r 0 Reduce the scale space param...

Embodiment 2

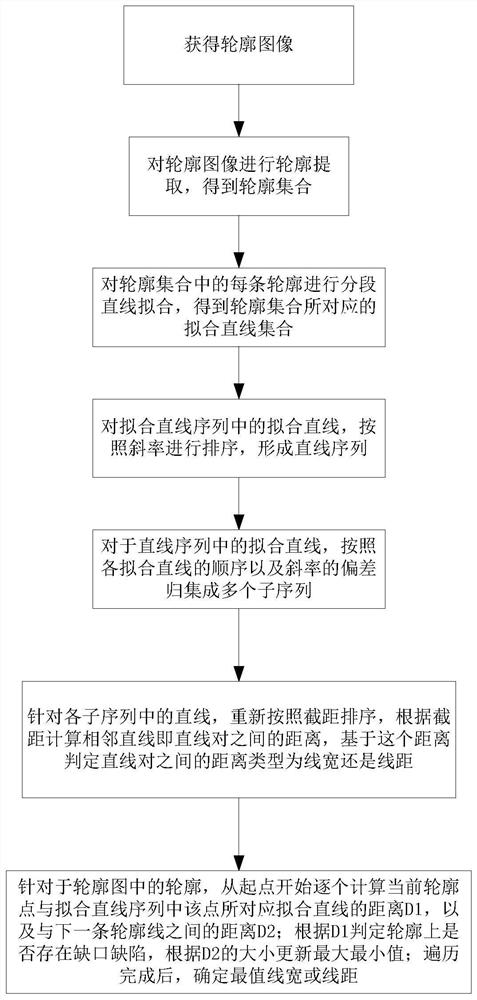

[0104] This embodiment discloses a method for detecting line width and distance defects of a flexible packaging substrate. For the flexible packaging substrate that needs to be detected, the contour image E is obtained through the method for detecting the contour of the flexible packaging substrate described in Embodiment 1; and then as follows figure 2 As shown in , perform the following steps:

[0105] Step S3, perform contour extraction on the contour image E to obtain a contour set U c , for the contour set U c Each contour in is fitted with a piecewise straight line to obtain the contour set U c The corresponding fitting line set U l =(U l1 ,U l2 … U li … U ln ), where U li Indicates the fitting straight line sequence corresponding to contour i, and n represents the number of contours; the details are as follows:

[0106] S31. For the starting point and the ending point of the contour, select p adjacent points respectively to perform coordinate smoothing processi...

Embodiment 3

[0137] This embodiment discloses a device for detecting the contour of a flexible packaging substrate, the steps of which include:

[0138] An image acquisition module, configured to acquire an image O of a flexible packaging substrate to be detected as an initial guide image;

[0139] The filtering module is used to perform texture removal and edge smoothing processing by using variable-scale iterative guided filtering for the image O of the flexible packaging substrate to obtain a filtered image Q;

[0140] The contour image generation module is used to process the filtered image Q by using the adaptive threshold segmentation algorithm of the Otsu method, and perform eight-neighborhood connection to obtain the contour image E.

[0141] For the specific implementation of the above-mentioned modules in this embodiment, reference may be made to the above-mentioned Embodiment 1, which will not be repeated here. It should be noted that the device provided in this embodiment is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com