Dialyzer batch production control method, dialyzer, dialysis system and dialyzer management method for batch production

A technology of mass production and control method, applied in dialysis systems, suction devices, etc., can solve the problems of increasing the production cost of manufacturers, increasing the error rate of wrong dialyzers, and failing to realize intelligent production management of dialyzers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

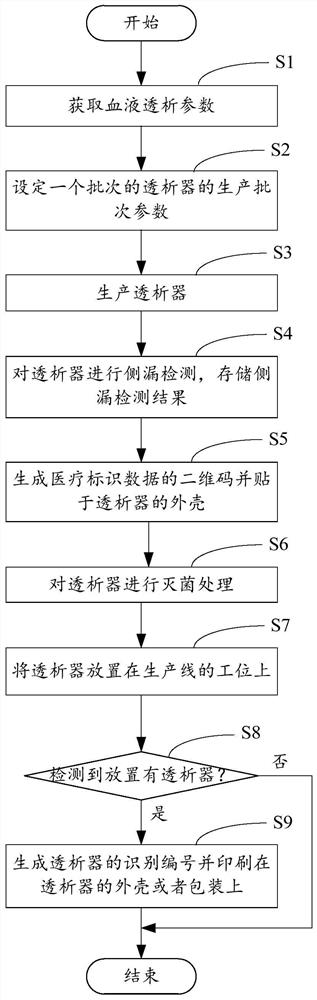

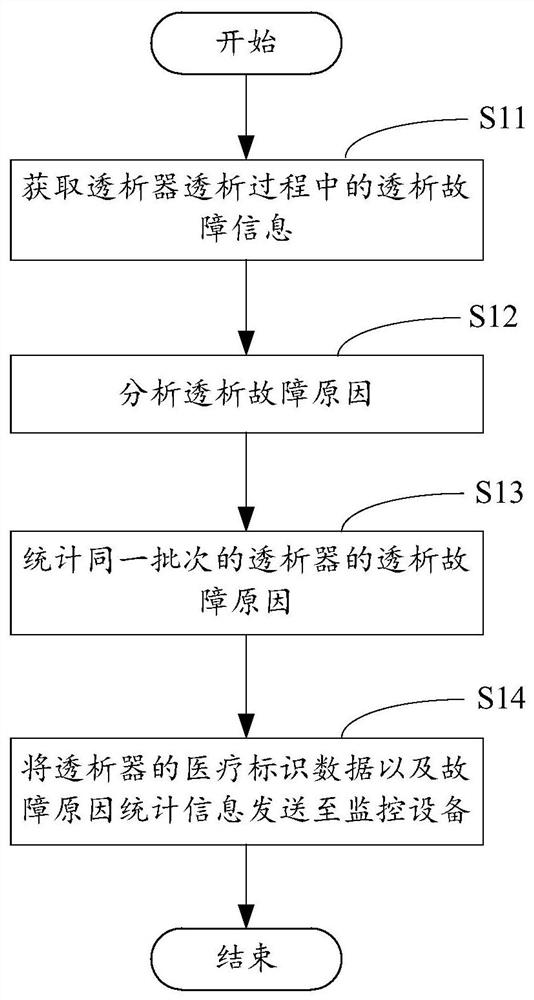

[0030] The dialyzer batch production control method of the present invention is used for batch production of dialyzers, and dialyzers with specific medical parameters are mass-produced according to patients of different age groups and different constitutions, so as to meet the use needs of different patients. The dialyzer of the present invention is a dialyzer mass-produced by the above-mentioned method, and the dialysis system has the above-mentioned dialyzer. The dialyzer management method of the present invention is aimed at the use management method of the dialyzer produced by the above method, through which the faults occurring during the use of the dialyzer are fed back, and statistical data is formed after analyzing the cause of the fault, so as to facilitate the production of the dialyzer by the manufacturer. The production process is improved to reduce the failure probability of subsequent dialyzers.

[0031] The batch production control method embodiment of dialyzer:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com