Construction waste resourceful treatment method

A construction waste and treatment method technology, applied in the field of construction waste recycling, can solve the problems of rough construction waste treatment methods, ecological environment hazards, less than 10%, and achieve good sorting effect, good quality, and fine separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

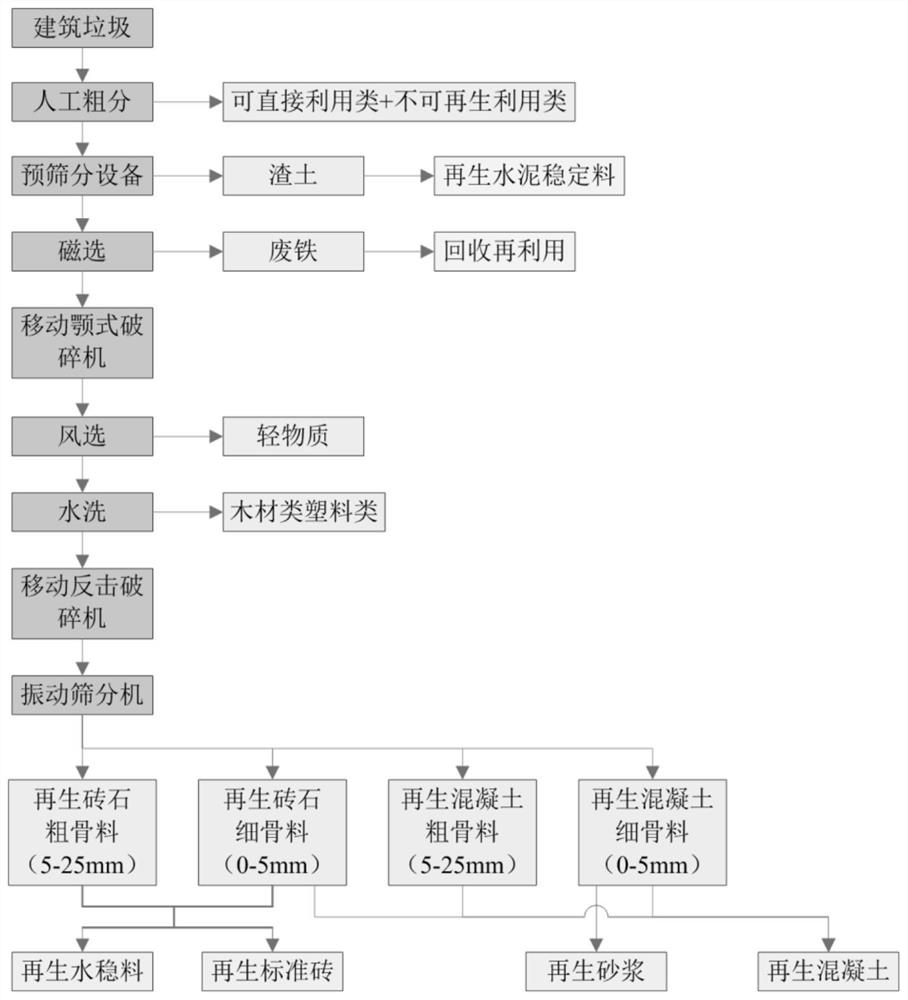

[0023] A construction waste resource processing method is carried out according to the following steps:

[0024] Step 1, rough classification of construction waste: classify the construction waste according to the degree of recyclability and stack them separately to the raw material warehouse;

[0025] Step 2, primary screening of construction waste: Send the waste in the raw material warehouse to the pre-screening equipment, screen out the dregs in it to make recycled cement stabilizers, and then send it to the magnetic separation equipment to select scrap iron and other materials for processing Recycling and reuse to obtain construction waste after primary screening;

[0026] Step 3, primary crushing and re-screening: the primary crushed construction waste obtained in step 2 is primary crushed with a mobile jaw crusher, and then subjected to winnowing to obtain primary crushed construction waste;

[0027] Step 4, secondary crushing and screening: use a mobile impact crusher...

Embodiment 2

[0030] On the basis of Embodiment 1, in step 1, classify the construction waste according to the degree of resource utilization, that is, the construction waste can be directly used, recycled and recycled, and non-recyclable, so as to reduce the cost of subsequent construction waste resource treatment. load and cost.

[0031] In step 2, the scrap iron is screened out for recycling.

[0032] In step 3, wind separation equipment for light substances is installed on the crushing and screening equipment, and the traditional process of sorting light substances by washing is changed to save water resources and solve the problem of secondary pollution.

[0033] In step 4, after screening by vibrating screening machine, two grades and two types of aggregates are screened out, namely recycled masonry fine aggregate, recycled masonry coarse aggregate, recycled concrete fine aggregate, recycled concrete Coarse aggregate.

[0034] In step 4, the particle size of the regenerated masonry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com