Machining method of special-shaped bearing bush

A processing method and special-shaped shaft technology, which are applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problems of inaccurate inclination of cutting bevel, easy damage of turning tools, etc., and achieve uniform force, not easy to damage, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

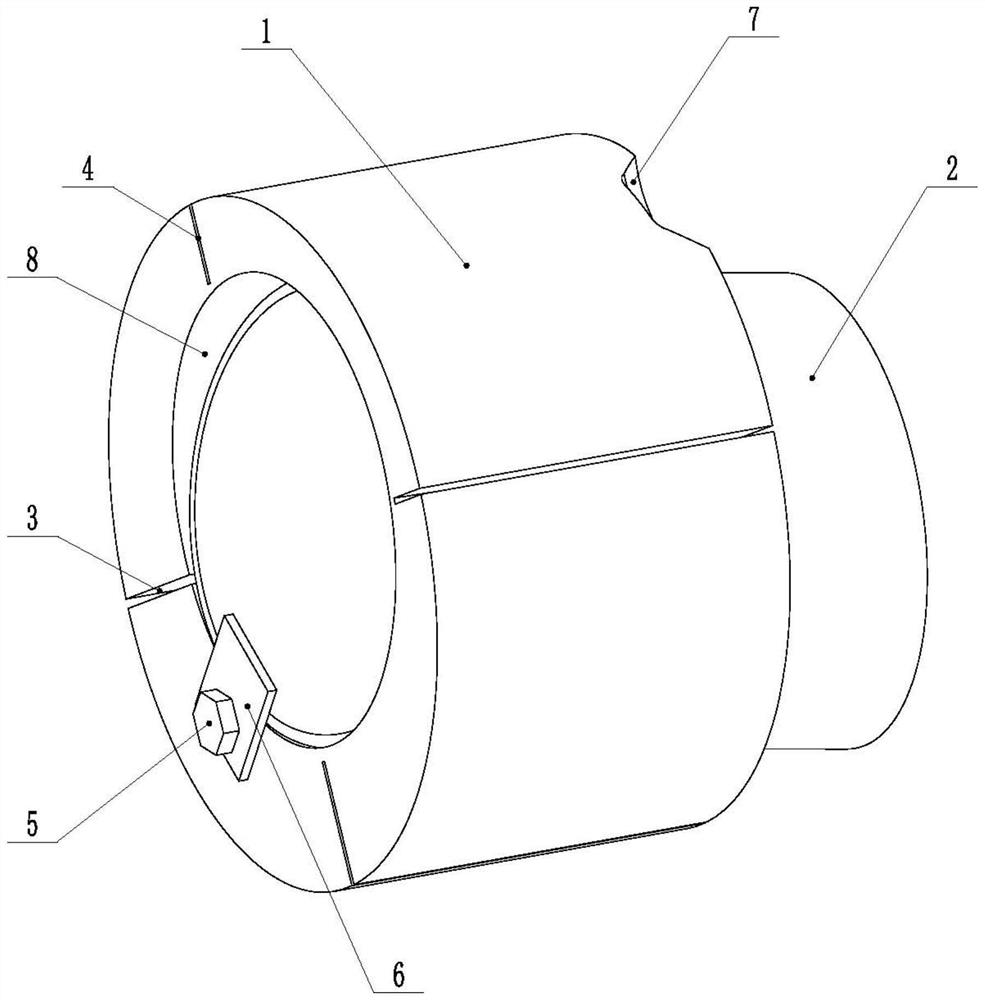

[0035] see details figure 1 :

[0036] A processing method for a special-shaped bearing bush, comprising the following steps:

[0037] Need to use a fixture, the fixture includes a base 1, the base 1 can be made of No. 45 steel, or spring steel, the base 1 is a cylinder, and the base 1 is provided with an inclined hole 8, which is eccentrically opened on the base 1. The inclination of the inclined hole 8 is greater than 0° and less than or equal to 21.3°. In this embodiment, the inclination of the inclined hole 8 is 12°. There is a threaded hole on the left end wall of the base body 1, and a stopper 6 and a hexagonal bolt 5 are also included. , There is a through hole on the block 6, the hexagonal bolt 5 passes through the through hole and is screwed into the threaded hole, the upper side of the block 6 is used to block part of the inclined hole 8, and there is a first expansion joint 3 and three The second expansion joint 4, the first expansion joint 3 and several second ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com