Industrial waste salt treatment method and treatment device

A treatment method and technology of industrial waste salt, applied in water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., can solve the problems of high energy consumption and difficult reuse of downstream industrial inorganic salts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

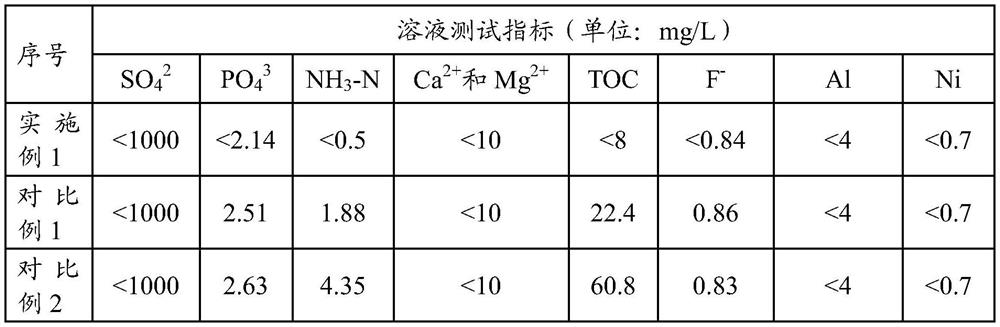

Embodiment 1

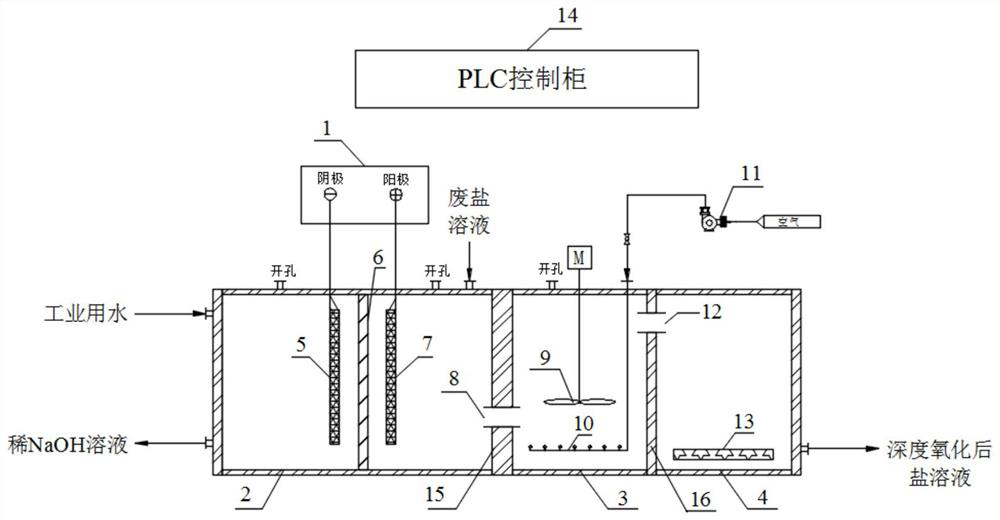

[0089] This embodiment is a treatment method for industrial waste salt, including a physical and chemical treatment section, a deep oxidation section and a salt production section, wherein the specific treatment process of each section is as follows:

[0090] S1) Physical and chemical treatment section

[0091] 1. Thermally dissolve organic matter and waste salt with an ammonia nitrogen content of 0.2-2% at 40-60°C to obtain a saturated solution of waste salt;

[0092] 2. Carry out chemical dosing to the saturated solution of waste salt to remove impurities, through a specific dosing sequence and dosing control program, the operation steps are as follows:

[0093] 1) adjust the pH value of the saturated solution of waste salt to 9.5-11.5, and precipitate the Mg contained in the saturated solution of waste salt 2+ , Fe 3+ other impurities;

[0094] 2) Add excess calcium reagent (CaCl 2 , Ca(OH) 2 ) to remove more PO in the waste salt solution 4 3- and F - Etc. Calcium r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com