High and low pressure bypass control system for intermediate reheating unit in power generation industry

A bypass system, high-pressure bypass technology, applied in control systems, machines/engines, steam generation, etc., can solve problems such as over-burning thrust tile accidents, high accident rates, and complex layout of high- and low-pressure bypass systems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

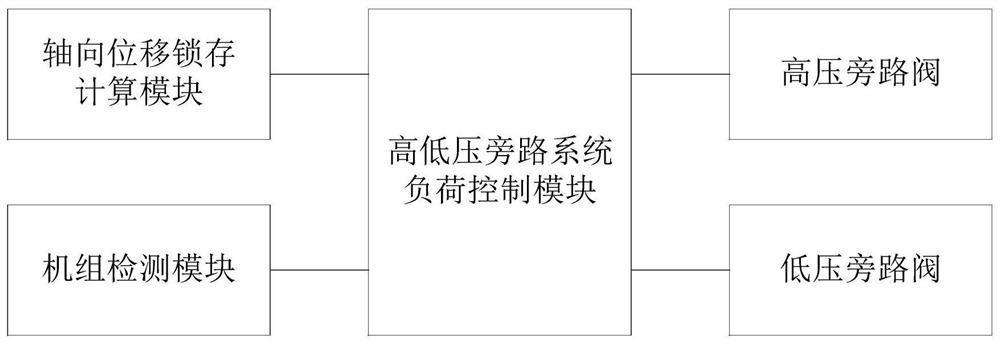

[0029] figure 1 It is a functional block diagram of the high and low pressure bypass control system of the intermediate reheat unit used in the power generation industry of the present invention.

[0030] In this example, if figure 1As shown, this embodiment provides a high and low voltage bypass control system for waste power generation industry, which includes: a high and low voltage bypass system load control module, electrically connected to the high and low voltage bypass system load control module The axial displacement lock calculation module, the unit detection module, the high pressure bypass valve and the low pressure bypass valve; wherein the high and low pressure bypass system load control module is suitable for locking the current axial displacement value according to the operating state of the steam turbine, and controlling the corresponding The bypass valve performs loading or unloading actions; the axial displacement latch calculation module is suitable for ca...

Embodiment 2

[0044] Figure 5 It is a flow chart of the boiler parallel steam automatic loading method of the present invention.

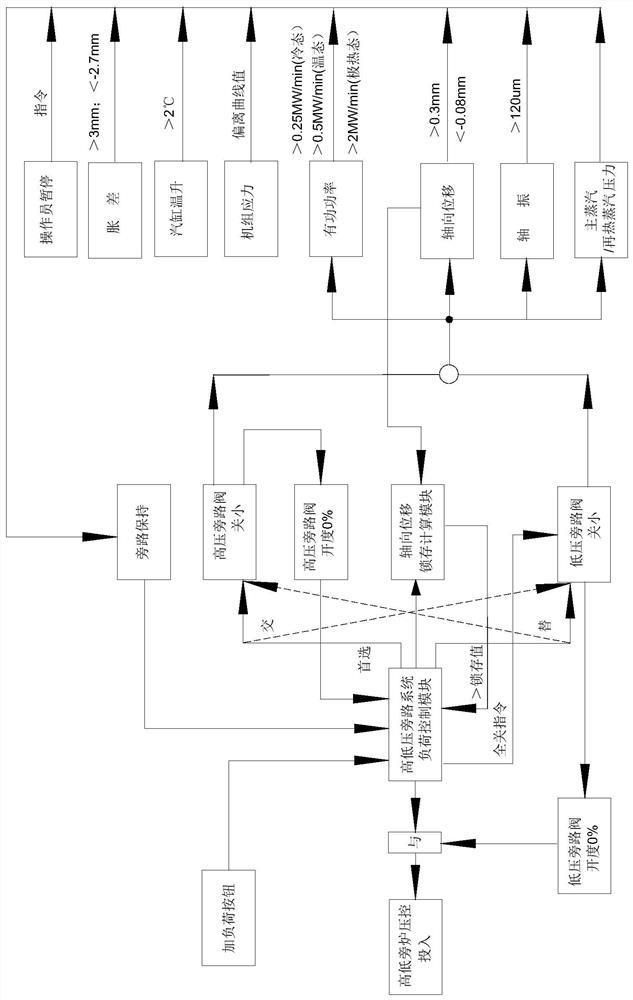

[0045] On the basis of Example 1, such as Figure 5 As shown, this embodiment provides an automatic loading method for the intermediate reheat unit after the boiler is combined with steam, which includes: after the boiler is started and steamed, lock the current axial displacement value of the steam turbine, and gradually reduce the corresponding high Bypass valve: real-time detection of unit load increase rate, cylinder temperature increase rate, expansion difference change and unit stress, when the cylinder temperature increase rate and expansion difference change reach the set value, the high-pressure bypass valve stops closing and keeps at Warm up the engine at this opening; calculate the difference between the axial displacement increase and the locked axial displacement value, stop closing the high-pressure bypass valve when the difference reaches the se...

Embodiment 3

[0049] Figure 6 It is a flow chart of the automatic load reduction method for boiler disassembly of the present invention.

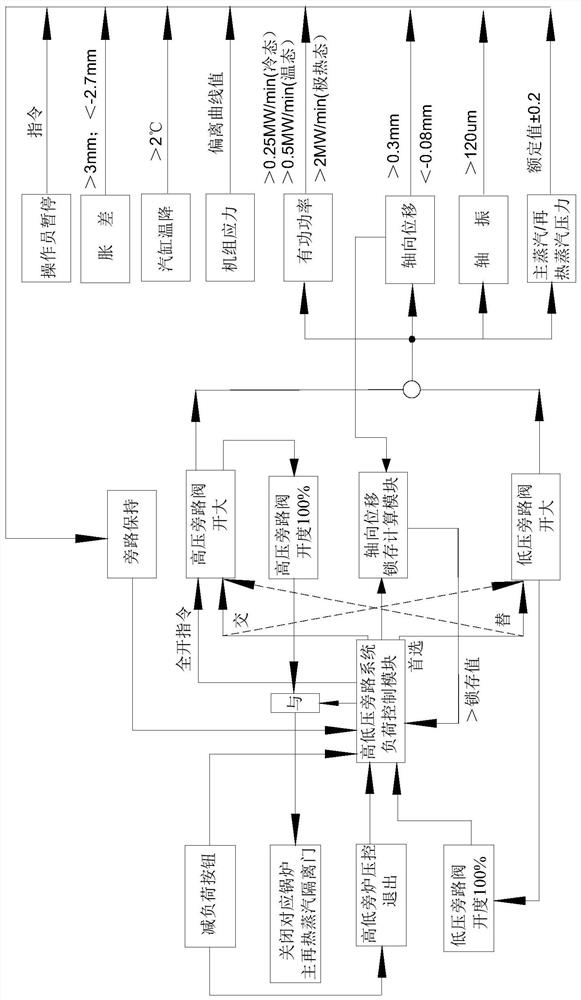

[0050] On the basis of the above examples, if Figure 6 As shown, this embodiment provides an automatic load reduction method for boiler delisting, which includes: after setting the boiler to be decommissioned and out of service, lock the current axial displacement value of the steam turbine, and gradually increase the corresponding low pressure bypass at a set rate. By-pass valve; real-time detection of unit load drop rate, cylinder temperature drop rate, expansion difference change and unit stress, when any parameter reaches the corresponding set value, the low-pressure bypass valve stops opening and keeps it at the opening for warm-up ; Calculate the difference between the axial displacement reduction and the locked axial displacement value, stop opening the low-pressure bypass valve when the difference reaches the set value, and start to open the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com