Frame adhesive force testing equipment and testing method thereof

A test method and adhesive force technology, applied in measuring devices, instruments, mechanical devices, etc., can solve problems such as inaccurate test results of sealant, and achieve the effect of monitoring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

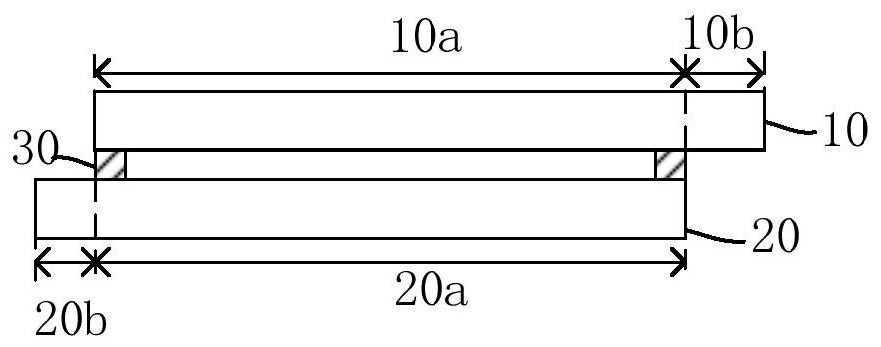

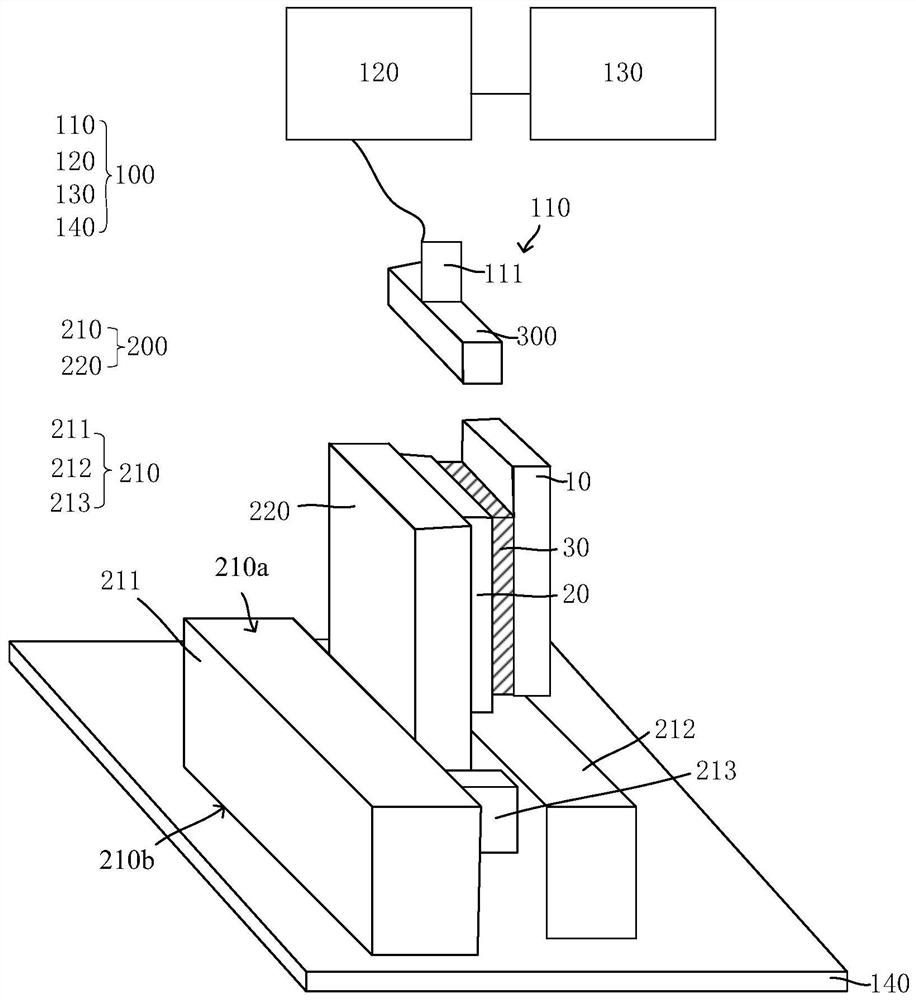

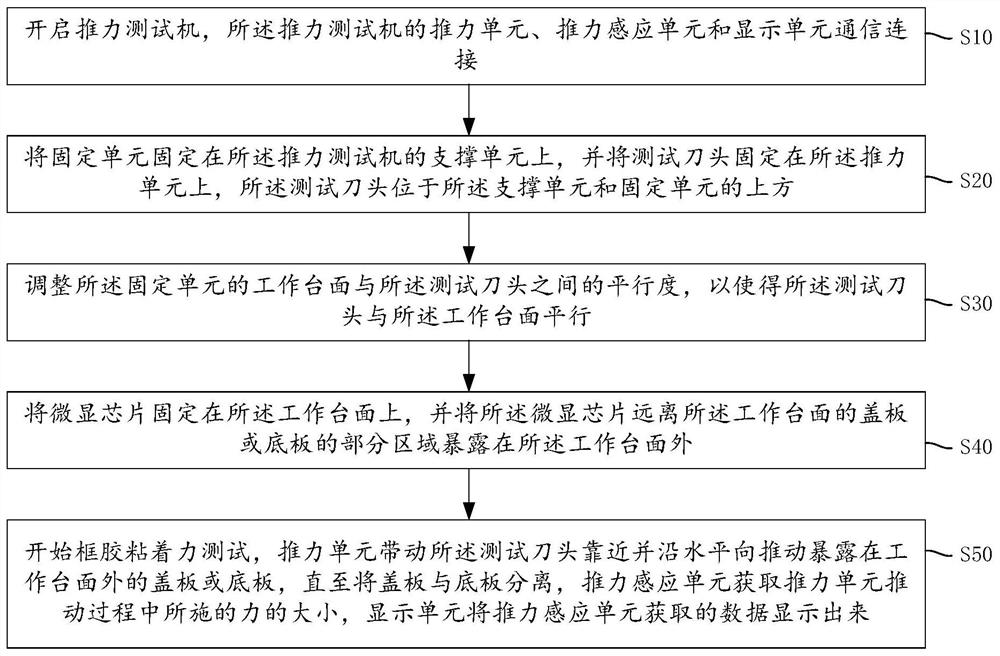

[0060] figure 1 It is a schematic diagram of the cross-sectional structure of the micro-chip of the first embodiment. Such as figure 1 As shown, the microscopic chip includes a cover plate 10 and a bottom plate 20. The cover plate 10 is, for example, a glass substrate, and the bottom plate 20 is, for example, a semiconductor chip. The cover plate 10 and the bottom plate 20 are connected by a sealant 30. Specifically, The cover plate 10 and the bottom plate 20 are connected in a closed ring shape on the opposite surfaces of the cover plate 10 and the bottom plate 20 through the frame glue 30 to seal the cover plate 10 and the bottom plate 20 surrounded by the frame glue 30 internal environment.

[0061] In this embodiment, a partial area of the cover plate 10 and a partial area of the bottom plate 20 are located outside the sealant 30 , and they are disposed on opposite sides of the sealant 30 . Specifically, the cover plate 10 includes a first area 10a and a second area...

Embodiment 2

[0094] The difference between this embodiment and Embodiment 1 is that the surface of the cover plate of the microscopic chip away from the bottom plate is fixed on the working surface of the fixing unit 200, and the projection on the plane where the working surface is located is located at the work surface.

[0095] Specifically, the projection of the first area 20a on the plane of the work surface is located on the work surface, and the projection of the second area 20b on the plane of the work surface is located outside the work surface. During the frame glue adhesion test, on the surface of the bottom plate 20 facing the cover plate 10, the thrust unit 110 exerts a thrust away from the cover plate 10 on the bottom plate 20, so as to connect the frame glue The cover plate 10 and the bottom plate 20 are separated.

[0096] The second area 20b is located on the other three directions of the work surface except the side facing the support unit. Preferably, the second area 20b...

Embodiment 3

[0105] Figure 4 It is a schematic diagram of the cross-sectional structure of the micro-chip of this embodiment. Such as Figure 4As shown, the difference between the present embodiment and the first embodiment is that part of the base plate 20 of the frame adhesive adhesion testing device is located outside the frame adhesive 30, and at this time, the cover plate 10 only includes the second An area 10a, the bottom plate 20 includes a first area 20a and a second area 20b connected to each other, the cover plate 10, the first area 20a and the second area 20b are, for example, rectangular, and the first area 10a and The first area 20a overlaps and is closed by the sealant 20, and the second area 20b is exposed outside the sealant.

[0106] The surface of the cover plate of the microscopic chip away from the bottom plate is fixed on the working table of the fixing unit 200 , and the projection on the plane where the working table is located is located on the working table. Sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com