A method for detecting the etching ability of pattern structure

A detection method and pattern structure technology, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to improve the stability of the etching process and ensure the reliability of the etching process through long-term testing of the etching capacity, the invention provides a method for detecting the etching capacity of the pattern structure.

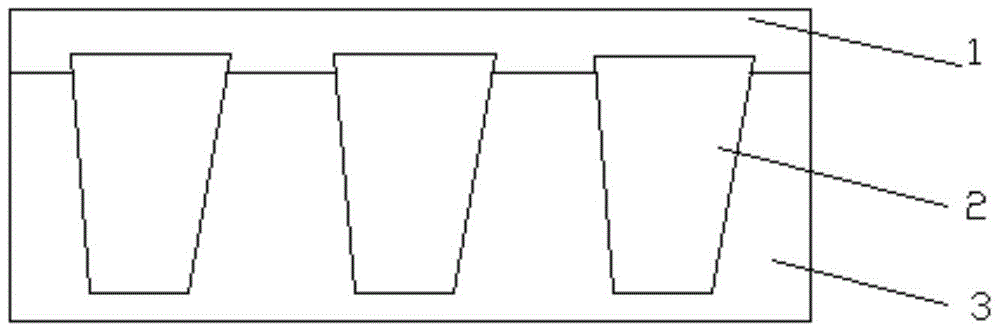

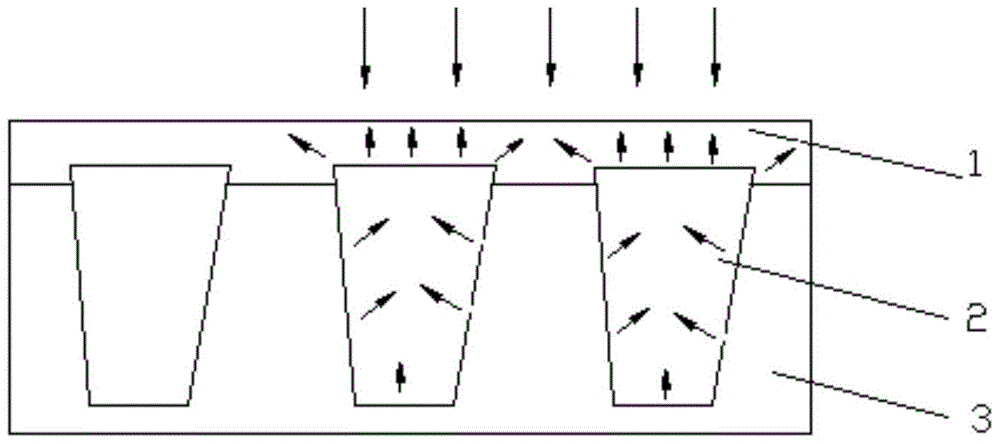

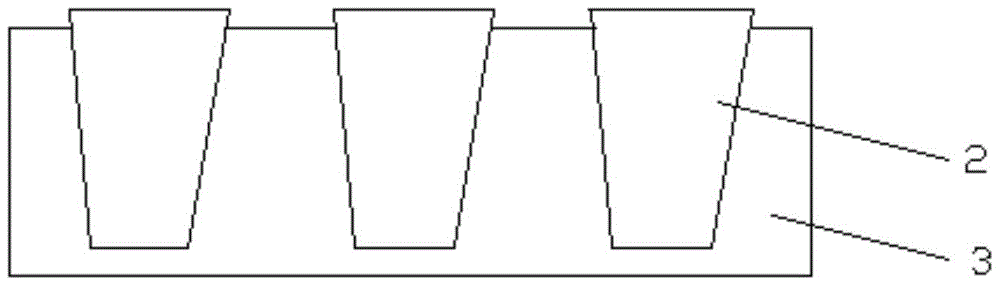

[0031] Specifically, such as Figures 6A-9 As shown, a semiconductor substrate including several active regions 3 and an oxide isolation layer covering the surface is provided, and an STI (Shallow Trench Isolation, shallow trench isolation) structure 2 is arranged in the active region 3, and each active region The source region 3 is surrounded and spaced apart by the STI structure 2, such as Figure 6A and Figure 6B shown. In an optional but non-limiting embodiment, a plurality of active regions 3 are arranged, arranged in a row, and used as a plurality of monitoring structures or test structures (3a 1 、3a 2 、3a 3 …3a n ), note that n is a natural number that is not zero, the test structure (3a 1 、3a 2 、3a 3 …3a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com