A kind of proton exchange membrane fuel cell anti-reverse anode pt/wo 3 -mn catalyst and preparation method thereof

A proton exchange membrane and fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of cumbersome catalyst preparation process, poor oxide conductivity, and mass transfer problems, and achieve excellent initial performance, low cost, The effect of high retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Dissolve 0.825g of sodium tungstate, 0.56g of sodium chloride and 0.283g of manganese sulfate in 19mL of deionized water. After stirring evenly, add 3M HCl solution dropwise until the pH is 2. Transfer the solution to a Teflon-lined In an autoclave, react at 180° C. for 3 h, after natural cooling, wash the reaction product with deionized water, and put it in a vacuum oven overnight. The dried product was carefully ground and annealed in a tube furnace at 400°C for 2h to obtain a catalyst support.

[0038] Weigh 14.6 mg of catalyst carrier and ultrasonically disperse it in 50 mL of ethylene glycol solution, then add 0.5 mM chloroplatinic acid solution, react the mixture at 140 ° C for 3 h, wash the product with a large amount of deionized water, and place it in a vacuum oven to dry 12h.

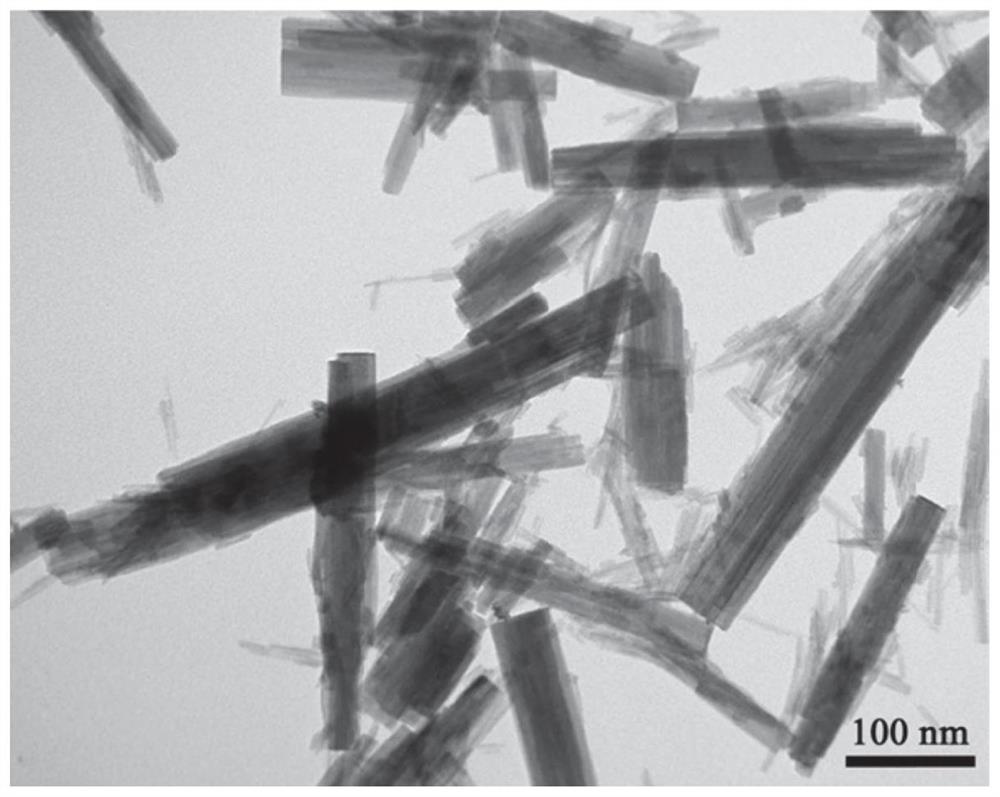

[0039] Taking Example 1 as an example, figure 1 WO provided for this application 3 - The Mn catalyst carrier, which is rod-shaped in appearance and has a diameter of 50-100 nm.

[0...

Embodiment 2

[0043] Dissolve 0.825g of sodium tungstate, 0.56g of sodium chloride and 0.141g of manganese sulfate in 19mL of deionized water. After stirring evenly, add 3M HCl solution dropwise until the pH is 2. Transfer the solution to a Teflon-lined In an autoclave, react at 180° C. for 3 h, after natural cooling, wash the reaction product with deionized water, and put it in a vacuum oven overnight. The dried product was carefully ground and annealed in a tube furnace at 400°C for 2h to obtain a catalyst support.

[0044] Weigh 14.6 mg of catalyst carrier and ultrasonically disperse it in 50 mL of ethylene glycol solution, then add 0.5 mM chloroplatinic acid solution, react the mixture at 140 °C for 3 h, wash the product with a large amount of deionized water, and place it in a vacuum oven to dry 12h.

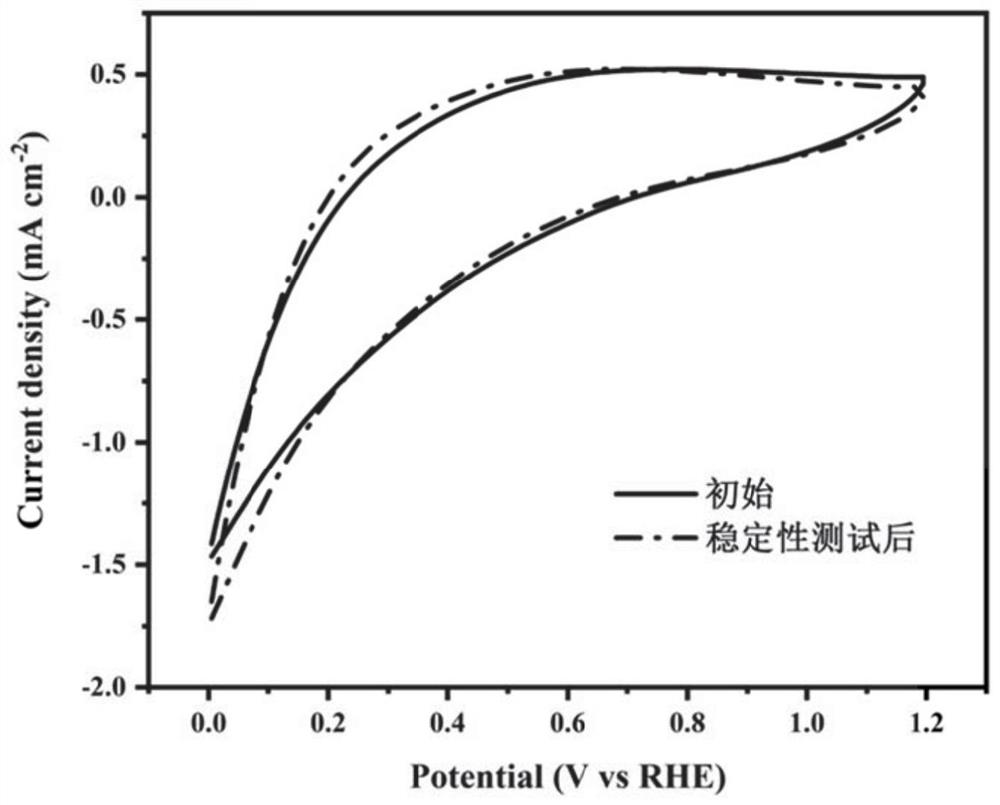

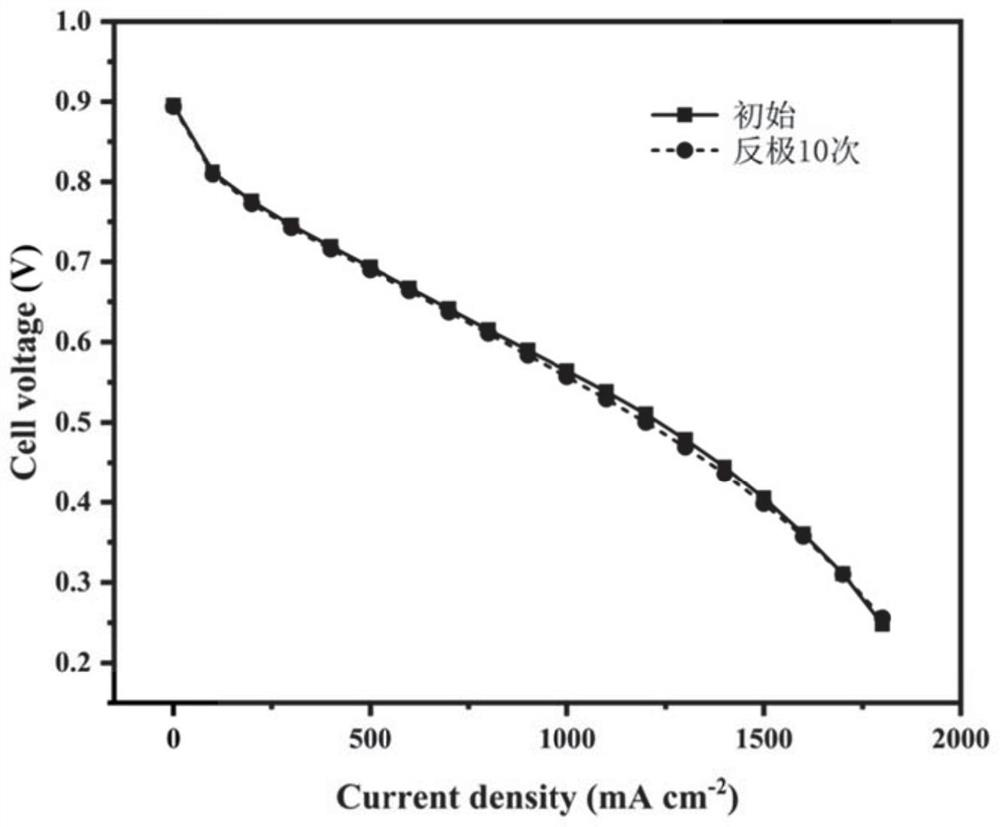

[0045] Taking Example 2 as an example, the anti-reverse catalyst prepared in Example 2 is prepared into a battery, Pt / WO 3 -The loading of Mn in the anode catalytic layer is 0.2mgcm -...

Embodiment 3

[0047] Dissolve 0.825g of sodium tungstate, 0.56g of sodium chloride and 0.071g of manganese sulfate in 19mL of deionized water, stir well, add 3M HCl solution dropwise until the pH is 2, and transfer the solution to a Teflon-lined In an autoclave, react at 180° C. for 3 h, after natural cooling, wash the reaction product with deionized water, and put it in a vacuum oven overnight. The dried product was carefully ground and annealed in a tube furnace at 400°C for 2h to obtain a catalyst support.

[0048] Weigh 39.02 mg of catalyst carrier and ultrasonically disperse it in 50 mL of ethylene glycol solution, then add 0.5 mM chloroplatinic acid solution, react the mixture at 140 ° C for 3 h, wash the product with a large amount of deionized water, and place it in a vacuum oven to dry 12h, the catalyst was obtained.

[0049] Taking Example 3 as an example, the anti-reverse catalyst prepared in Example 2 was prepared into a battery, Pt / WO 3 -The loading of Mn in the anode catalyt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com