Freezing conduction liquid and preparation method thereof

A preparation method and technology of conducting liquid, which is applied in food freezing, meat/fish preservation through freezing/cooling, food science, etc., can solve the problems of tenderness, water holding capacity, gelling property and nutritional value fission, and frozen denaturation of meat protein , There are problems such as damage on the surface of the object, to achieve the effect of more glossy appearance, extended shelf life, refrigeration and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

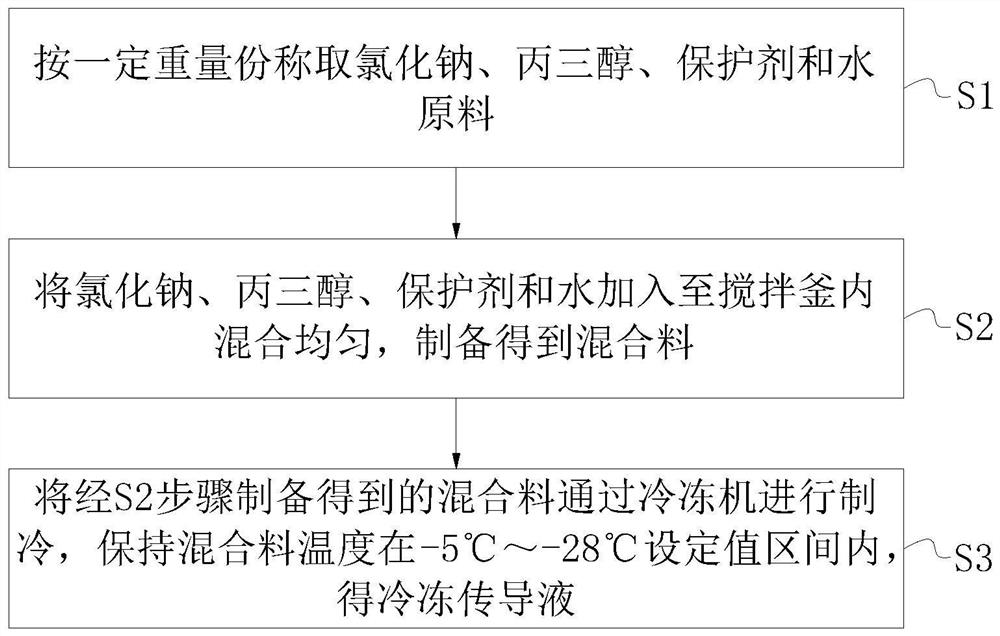

[0029] see figure 1 , The present invention provides the following technical solutions: a cryotransfer liquid, the cryotransfer liquid is composed of the following raw materials in parts by weight: 15 parts of sodium chloride, 15 parts of glycerol, 7 parts of glucose, and 63 parts of water.

[0030] The present invention also provides a preparation method of frozen conduction fluid, comprising the following steps:

[0031] Step S1, weighing sodium chloride, glycerol, protective agent and water raw materials in certain weight parts;

[0032] Step S2, adding sodium chloride, glycerin, protective agent and water into the stirring tank and mixing evenly to prepare a mixture;

[0033] Step S3, refrigerating the mixed material prepared in the step S2 through a freezer, keeping the temperature of the mixed material within the set value range of -20° C., to obtain a frozen conductive liquid.

[0034] Specifically, sodium chloride, glycerin, protective agent and water are uniformly m...

Embodiment 2

[0037] see figure 1 , The present invention provides the following technical solutions: a cryoconducting liquid, the cryoconducting liquid is composed of the following raw materials in parts by weight: 22 parts of sodium chloride, 22 parts of glycerol, 15 parts of sucrose, and 39 parts of water.

[0038] The present invention also provides a preparation method of frozen conduction fluid, comprising the following steps:

[0039] Step S1, weighing sodium chloride, glycerol, protective agent and water raw materials in certain weight parts;

[0040] Step S2, adding sodium chloride, glycerin, protective agent and water into the stirring tank and mixing evenly to prepare a mixture;

[0041] Step S3, refrigerating the mixed material prepared in the step S2 through a freezer, keeping the temperature of the mixed material within the set value range of -28° C., to obtain a frozen conductive liquid.

[0042] Specifically, the sodium chloride, glycerin, protective agent and water are un...

Embodiment 3

[0045] see figure 1 , The present invention provides the following technical solutions: a cryoconducting liquid, the cryoconducting liquid is composed of the following raw materials in parts by weight: 20 parts of sodium chloride, 20 parts of glycerol, 10 parts of trehalose, and 50 parts of water.

[0046] The present invention also provides a preparation method of frozen conduction fluid, comprising the following steps:

[0047] Step S1, weighing sodium chloride, glycerol, protective agent and water raw materials in certain weight parts;

[0048] Step S2, adding sodium chloride, glycerin, protective agent and water into the stirring tank and mixing evenly to prepare a mixture;

[0049] Step S3, refrigerating the mixed material prepared in the step S2 through a freezer, keeping the temperature of the mixed material within the set value range of -10° C., to obtain a frozen transfer liquid.

[0050] Specifically, the sodium chloride, glycerin, protective agent and water are un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com