Automatic dental cast forming system

A dental model and separation module technology, applied in dentistry, orthodontics, prosthetics, etc., can solve the problems of unguaranteed product quality and stability, reducing the production efficiency of invisible aligners, and limiting the production capacity of invisible aligners. , to save manpower and time costs, realize automatic control, and reduce dental mold damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The description of preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings to more clearly and completely explain the technical solutions of the present invention.

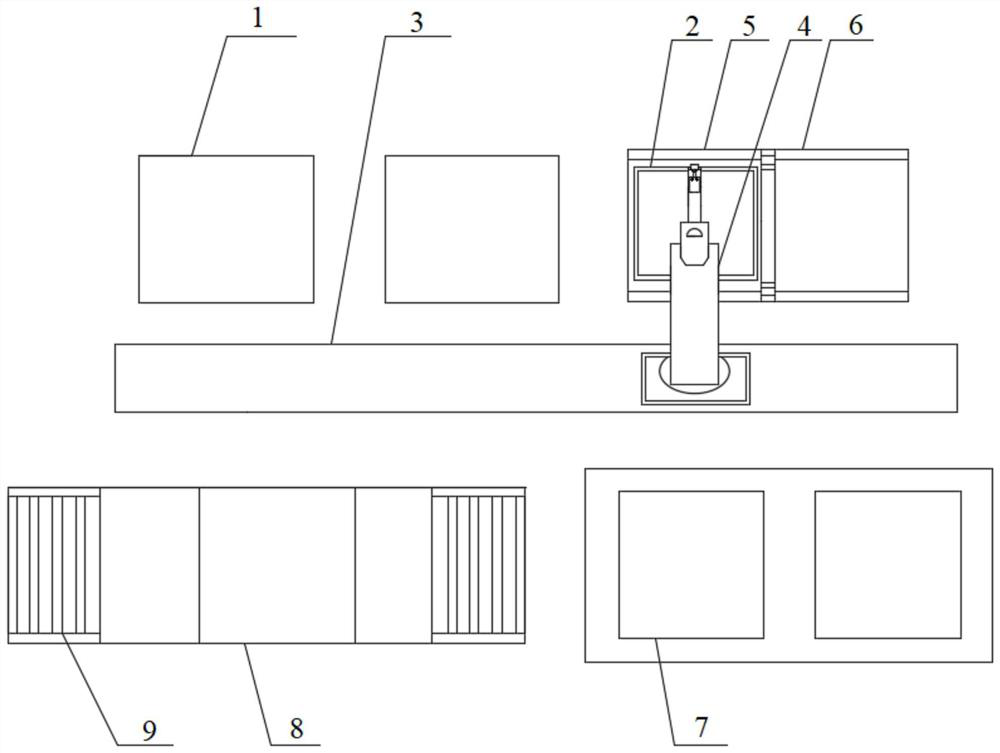

[0029] Such as figure 1 Shown is a preferred embodiment of an automated dental mold forming system, including a forming module, a transfer module, a separation module, and a post-processing module;

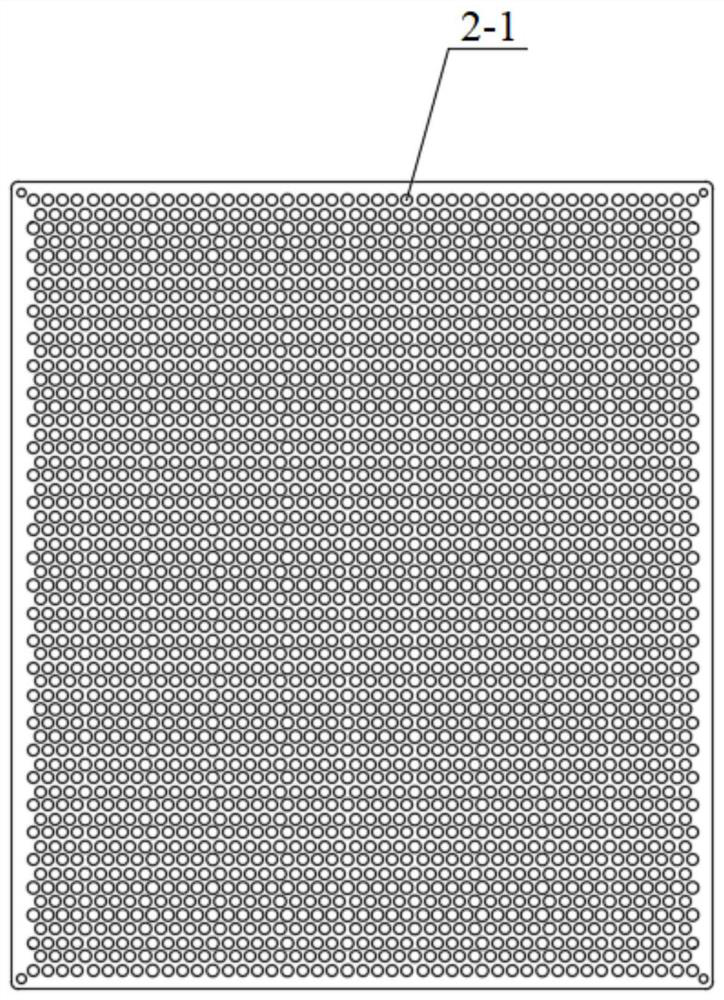

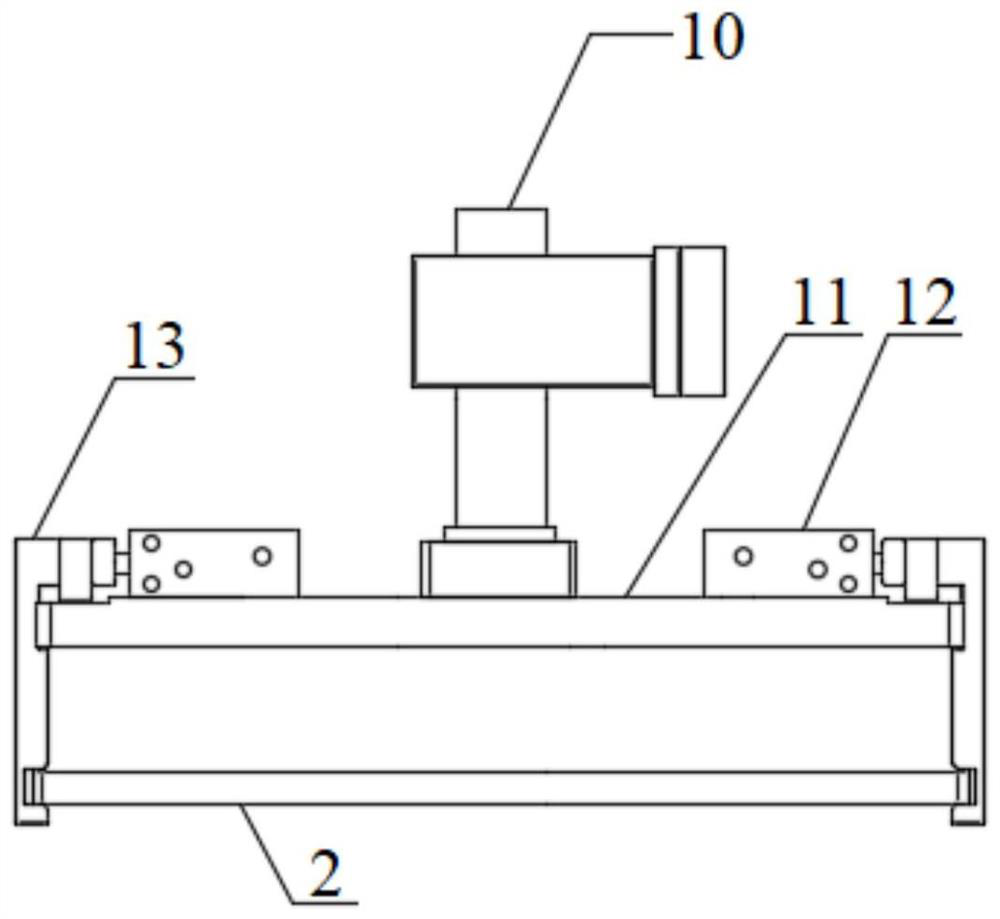

[0030] The forming module includes a plurality of 3D printers 1 and a printing panel 2 arranged in the 3D printer, and the 3D printer quickly forms a dental model on the printing panel according to the task requirements; the transfer module includes a ground rail 3 and a transfer robot arranged on the ground rail 3 4. It is used to realize the grabbing and transporting of the printing panel 2; the separation module includes a separation table 5 and a separation mechanism, and the separation of the dental mold on the separation table 5 from the printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com