Reagent tube cleaning device

A technology for cleaning devices and reagent tubes, applied in the biological field, can solve the problems of insufficient cleaning of reagent tubes, easy slipping, bumping and damage, affecting experimental results, etc., and achieves the effects of stable rotation, tight packaging, and improved cleaning speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

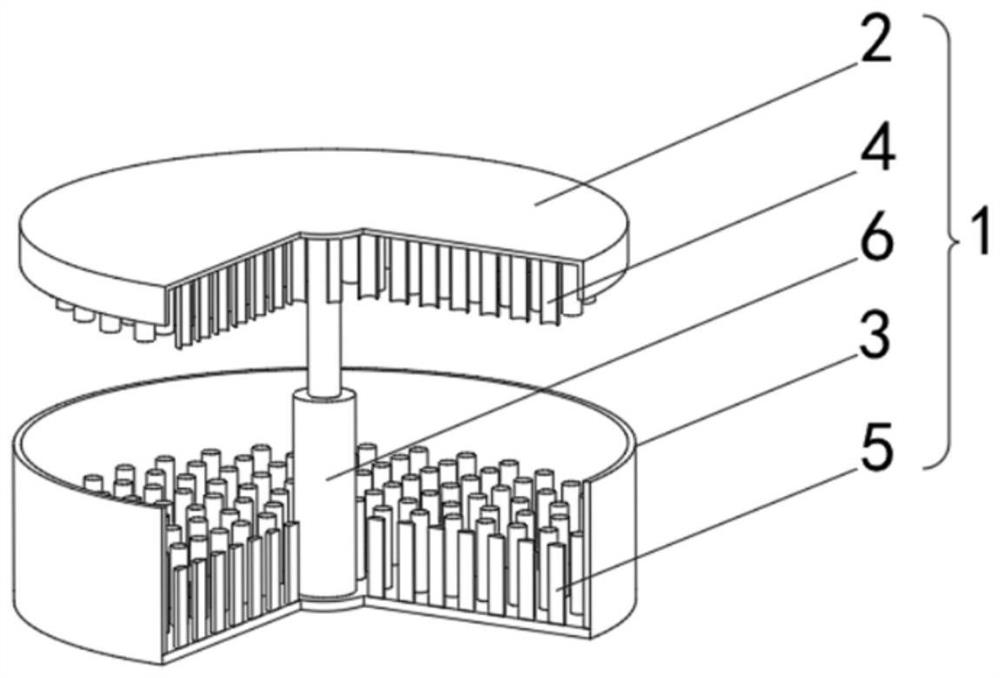

[0042]SeeFigure 1-2 The present invention provides a technical solution: a reagent tube cleaning device including a reagent tube cleaning apparatus body 1 composed of an upper cover 2, a lower tank 3, and a hydraulic telescopic rod 6, and a fixed connection of the inner wall of the upper cover 2 The fixing mechanism 4, the bottom of the lower tank 3 is rotated by the external micro motor, and the top portion of the inner wall of the upper cover 2 is fixed to the top of the hydraulic telescopic rod 4, the bottom portion of the inner wall of the lower tank 3 and the hydraulic telescopic rod 4 The bottom fixed connection.

[0043]The fixing mechanism 4 is located directly above the cleaning mechanism 5, and the fixing mechanism 4 is adapted to the cleaning mechanism 5.

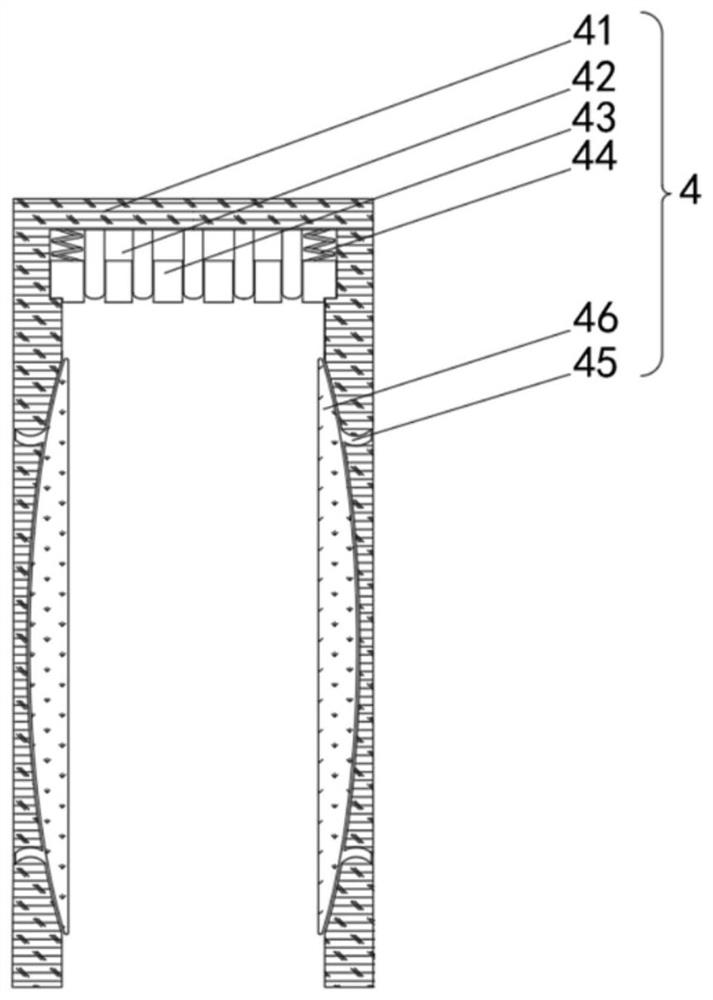

[0044]The fixing mechanism 4 includes a fixing frame 41, and the inner wall top of the fixed frame 41 is fixedly coupled with the inlaid block 42, and the inner sliding connection of the inlay block 42 has the abutment block...

Embodiment 2

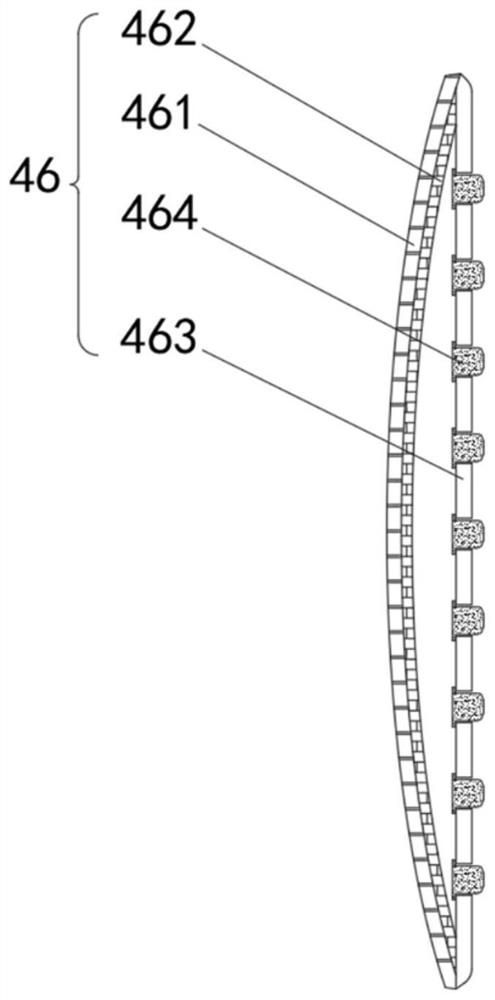

[0047]SeeFigure 1-4 Based on the example one, the present invention provides a technical solution: the anti-slip mechanism 46 includes a receiving strip 461, and the right side of the receiving strip 461 is fixedly connected to the electromagnetic strip 462, the right side of the receiving strip 461 is fixedly connected to the support strip 463. The inside of the support strip 463 is slidably connected to a protective mechanism 464.

[0048]The receiving strip 461 is filled with an inert gas inside the cavity enclosed in the support strip 463, and the electromagnetic strip 462 is in communication with the external power source.

[0049]The protective mechanism 464 includes a magnetic force block 4641, and the right side of the magnetic block 4641 is fixedly connected to the protective frame 4642, and the right side of the protective frame 4642 is fixedly connected to the flexible cotton 4643. The right side of the magnetic block 4641 is fixedly connected to the flexible strip 4644, flexib...

Embodiment 3

[0052]SeeFigure 1-7Based on the first embodiment and the second embodiment, the present invention provides a technical solution: the cleaning mechanism 5 includes a cleaning strip 51, and the bottom of the cleaning strip 51 is rotated by the return sheet 52, and the bottom of the cleaning plate 52 passes The outer micro motor is rotatably connected to the inner portion of the lower tank 3, and the inner side of the cleaning strip 51 is fixed, respectively, respectively, and the top fixed connection of the cleaning strip 51 is fixedly attached, and the outer side fixed connection of the cleaning strip 51 is fixed. There is a cleaning brush 56, and the top of the cleaning plate 52 is fixedly connected to the protective strip 57, and the top of the protective strip 57 extends to the inside of the cleaning strip 51 and is fixed to the cleaning strip 51.

[0053]The cleaning brush 56 includes a fluid plate 561, and the inside of the flow guide plate 561 is opened, and the right side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com