Fireproof door production equipment and manufacturing process

A technology for production equipment and fire doors, applied in manufacturing tools, metal processing equipment, punching tools, etc., can solve the problems of low punching efficiency, time-consuming and laborious, and achieve the effect of improving replacement efficiency, improving installation accuracy, and maintaining independence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

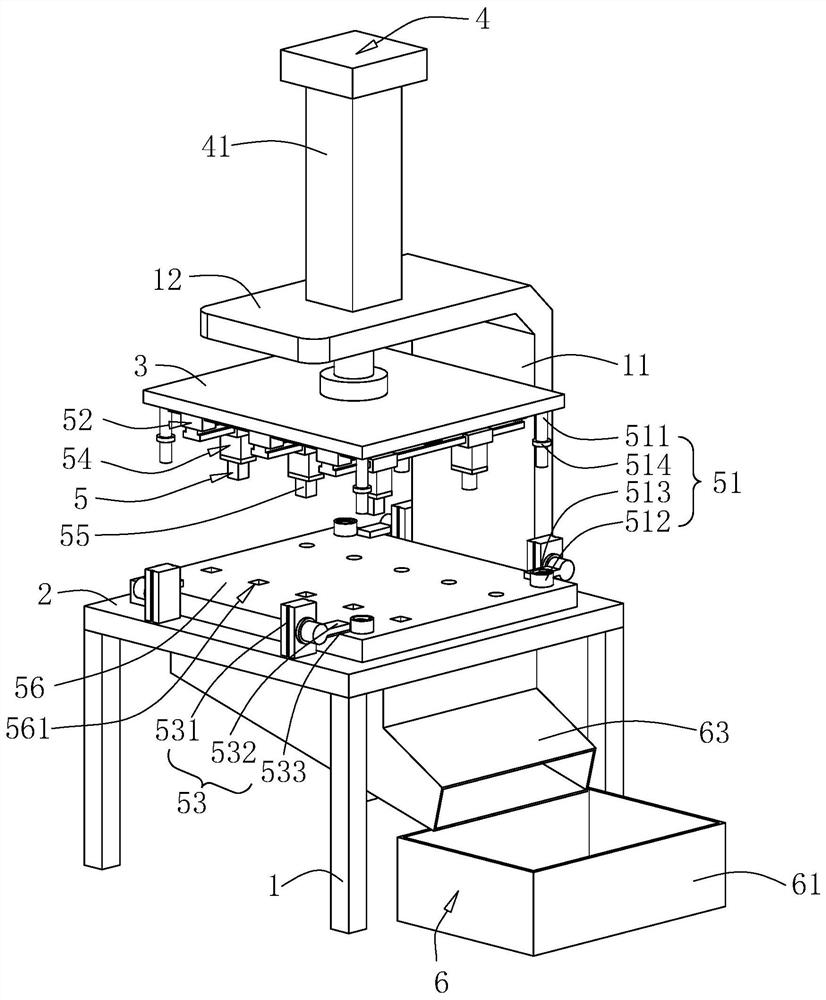

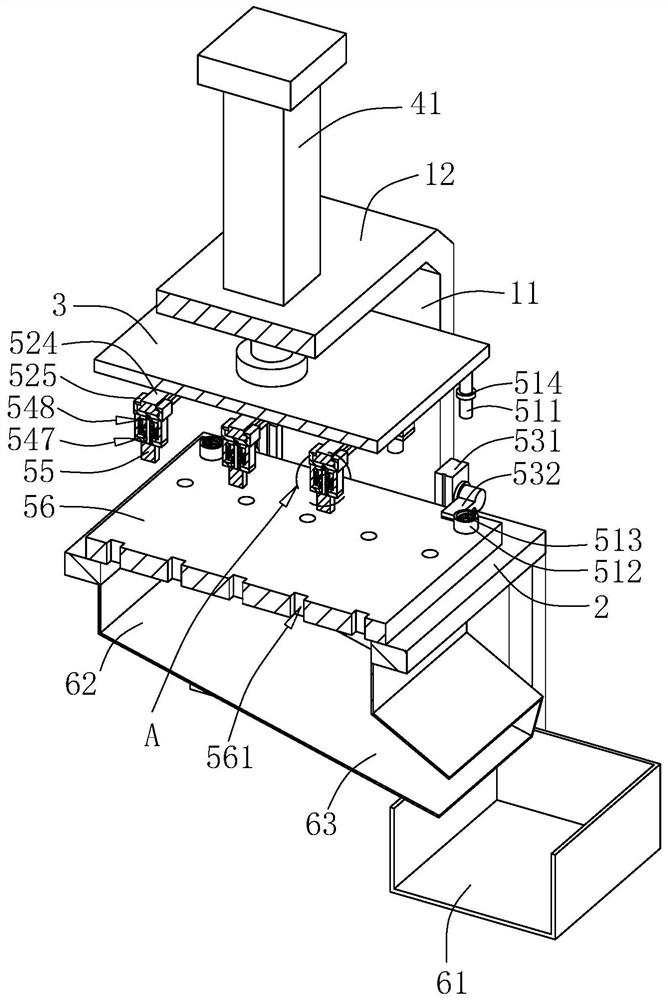

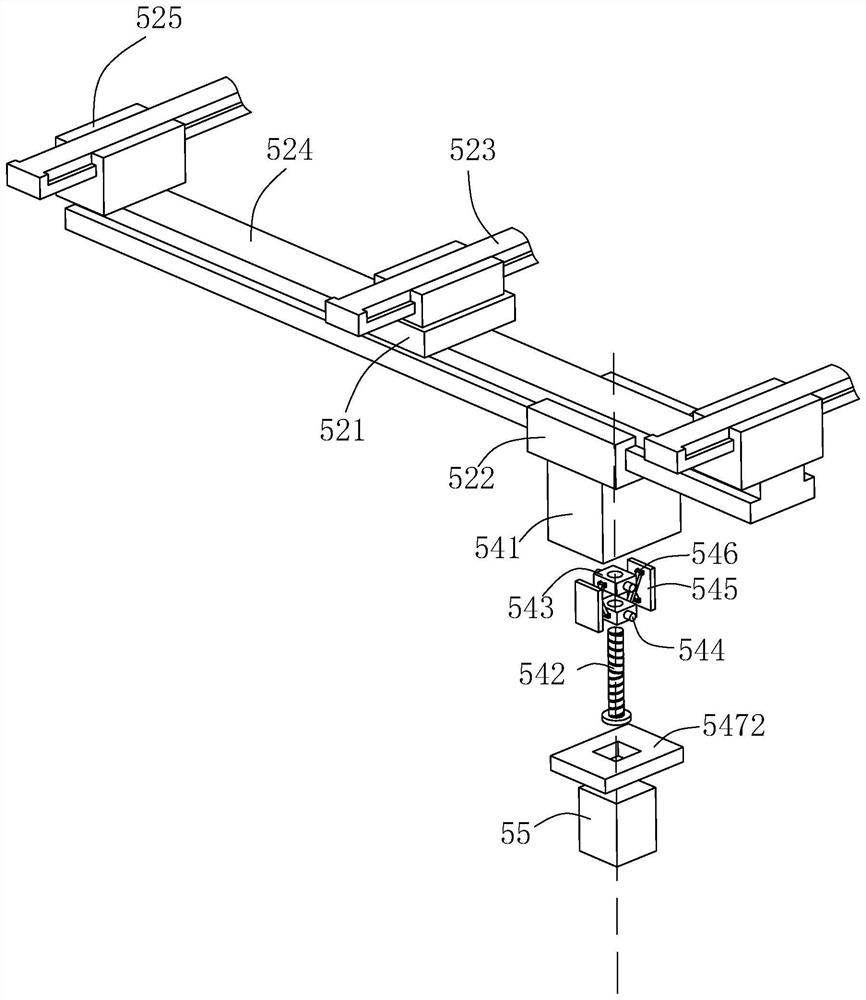

[0042] The following is attached Figure 1-4 The application is described in further detail.

[0043] The embodiment of the present application discloses a fire door production equipment. A fire door production equipment, including door leaf production equipment, door frame production equipment and a spraying machine, the door leaf production equipment sequentially includes a shearing machine, a punching machine, a bending machine, a door leaf occlusal roll forming machine, a perlite core board, a hot press Forming machines; door frame production equipment including door frame roll forming machines, cutting machines, door frame punching machines and welding stations.

[0044] refer to figure 1 , the punching machine includes a body 1, an operating table 2, a lower platen 3, a driving device 4, a punching device 5 and a waste collection device 6, the body 1 is fixed on the ground by collision bolts and set on the body 1, and the body 1 is welded with The side plate 11 arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com