High-frequency pulse laser pressure stress implantation rapid forming system and method

A high-frequency pulse, compressive stress technology, applied in the field of high-frequency pulse laser implanted compressive stress rapid prototyping system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

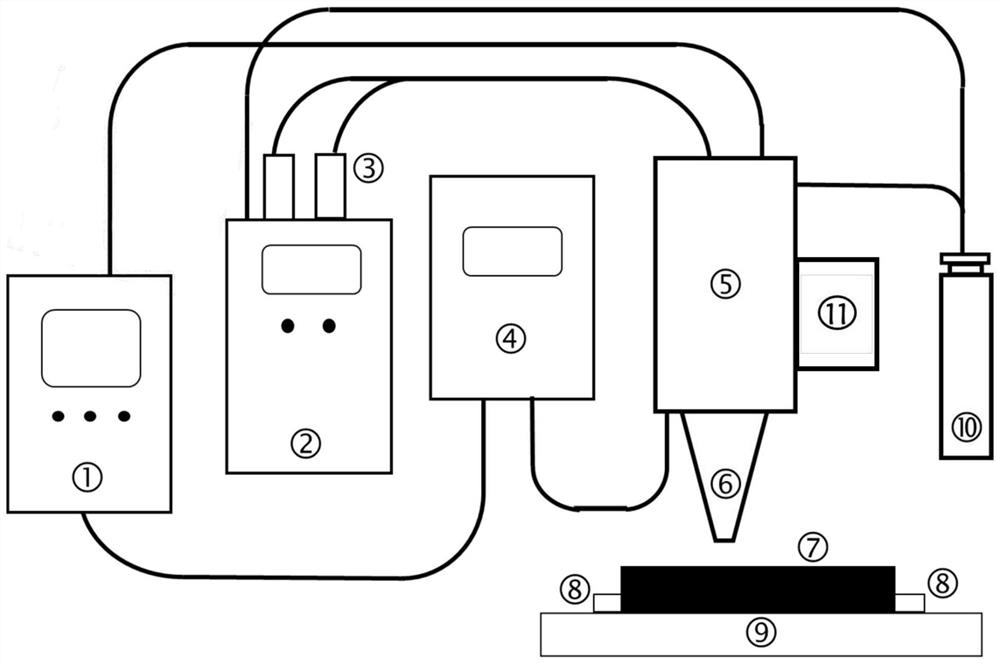

[0040] Such as figure 1 As shown, a high-frequency pulse laser implanted compressive stress rapid prototyping system includes: a laser control system 11, a high-frequency pulse laser generator 1, a powder feeder 2, a motion system 5, and a coaxial powder feeding laser cladding head 6 and an inert gas source 10 .

[0041] The laser control system 11 includes a PLC control system and a human-machine interface, which can control and display process parameters such as laser output power on the man-machine interface; and can store and automatically run process parameters.

[0042] According to the drawing requirements of the preformed metal parts, the CAD model of the preformed part is established, and the established C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com