Film slitting equipment

A technology of film slitting and equipment, which is applied in the direction of thin material processing, metal processing, winding strips, etc., can solve the problems of cutting position misalignment, affecting food packaging, and different sizes of slitting films, so as to reduce friction , Accelerate the conveying speed and reduce the effect of cutting position misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] as attached figure 1 to attach Figure 5 Shown:

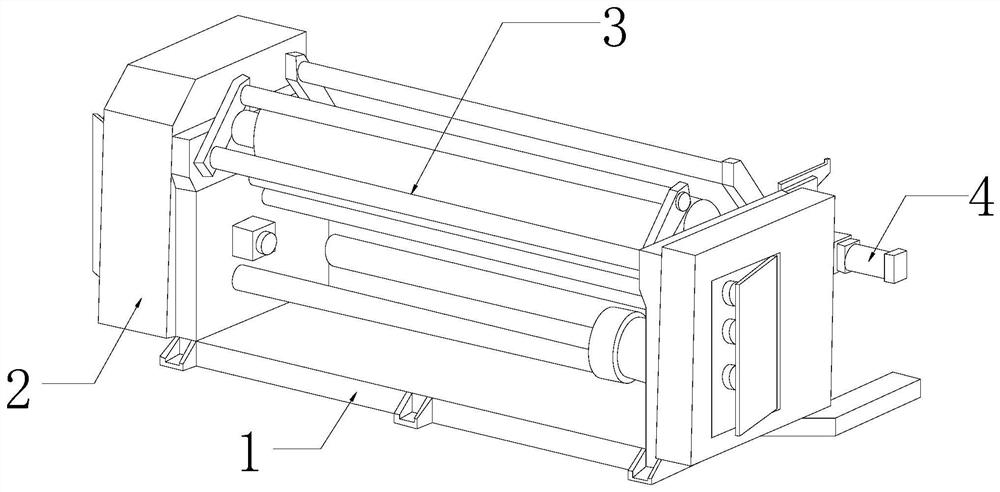

[0026] The invention provides a film cutting device, the structure of which includes a base 1, a body 2, a film frame 3, and a motor 4. The body 2 is respectively installed on the top of both ends of the base 1, and the film frame 3 is horizontally fixed on the body 2. Between, the motor 4 is installed on the back of the body 2.

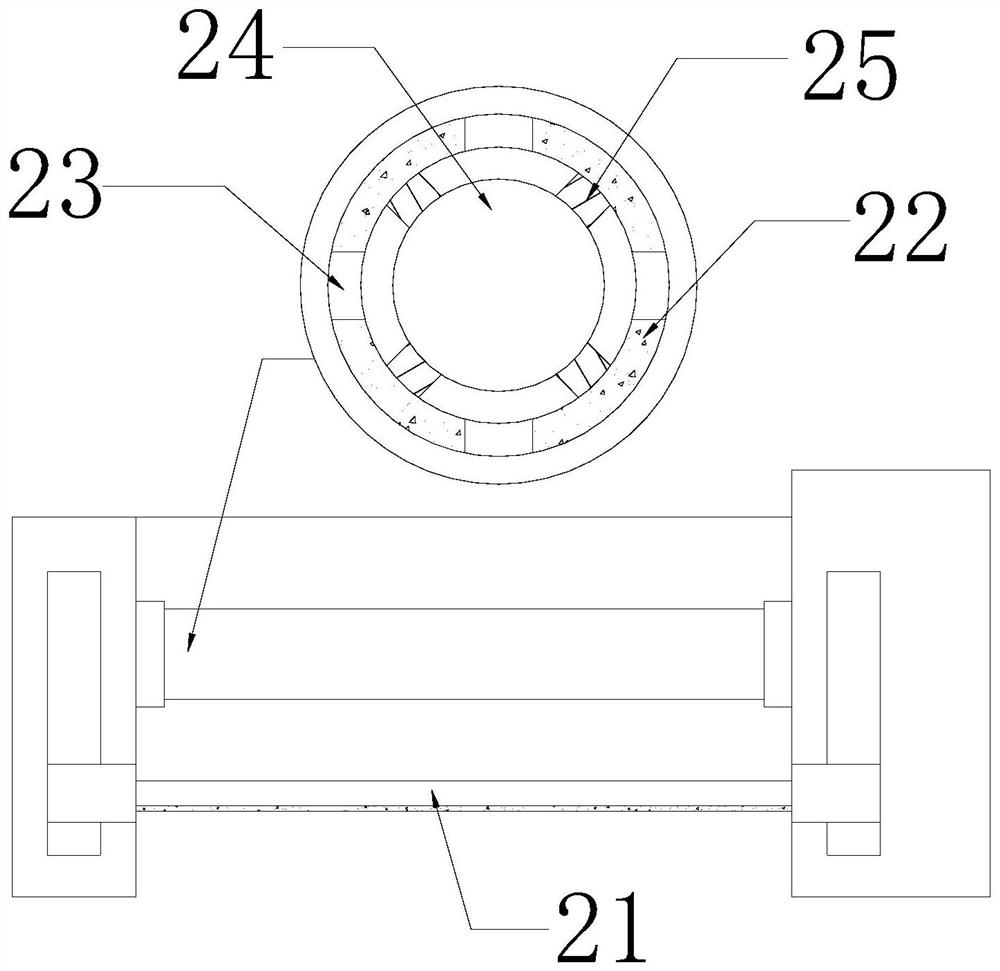

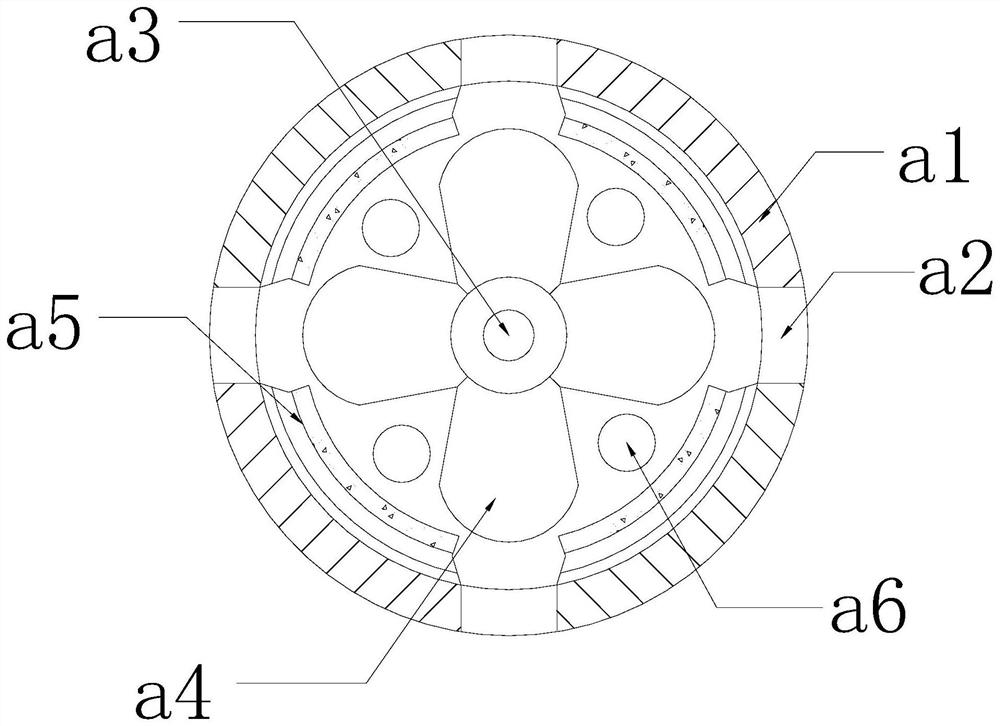

[0027] The body 2 is provided with a cutting knife 21, a rotating roller 22, an opening 23, a vibration mechanism 24, and a support block 25. The cutting knife 21 is installed at the bottom position between the bodies 2, and the rotating roller 22 is horizontally connected and installed on the Between the body 2 and above the cutting knife 21 , the opening 23 runs through between the outer wall and the inner wall of the rotating roller 22 , and the vibrating mechanism 24 is fixedly installed on the inner wall of the rotating roller 22 through a support block 25 .

[0028] Wherein, the vibrat...

Embodiment 2

[0034] as attached Figure 6 to attach Figure 7 Shown:

[0035] Wherein, the opening 23 is provided with a stacking cavity r1, a clamping plate r2, a bearing r3, a clamping block r4, a pull bar r5, and a pushing block r6. The stacking cavity r1 is respectively arranged on the inner wall of the opening 23, and the clamping plate r2 r3 is connected and installed on the top of the stacking chamber r1, the block r4 is integrated with the outside of the bottom of the stacking chamber r1, the tie bar r5 is connected between the inner side of the clamping plate r2 and the inner wall of the stacking chamber r1, and the pushing block r6 It is arranged inside the storage chamber r1 and movably cooperates with the clamping plate r2. The storage chamber r1 is at an inclined angle, allowing liquid to flow in along the slope of the storage chamber r1 and reducing liquid backflow.

[0036] Wherein, the clamp r2 is provided with a plate body t1, a groove t2, an elastic strip t3, and a push b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com