Oil-electric hybrid injection molding machine

An injection molding machine, oil-electric technology, applied in the field of oil-electric hybrid injection molding machine, can solve the problems of high injection molding cost, low utilization rate of servo motor, low utilization efficiency of motor, etc., and achieve the effect of convenient implementation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

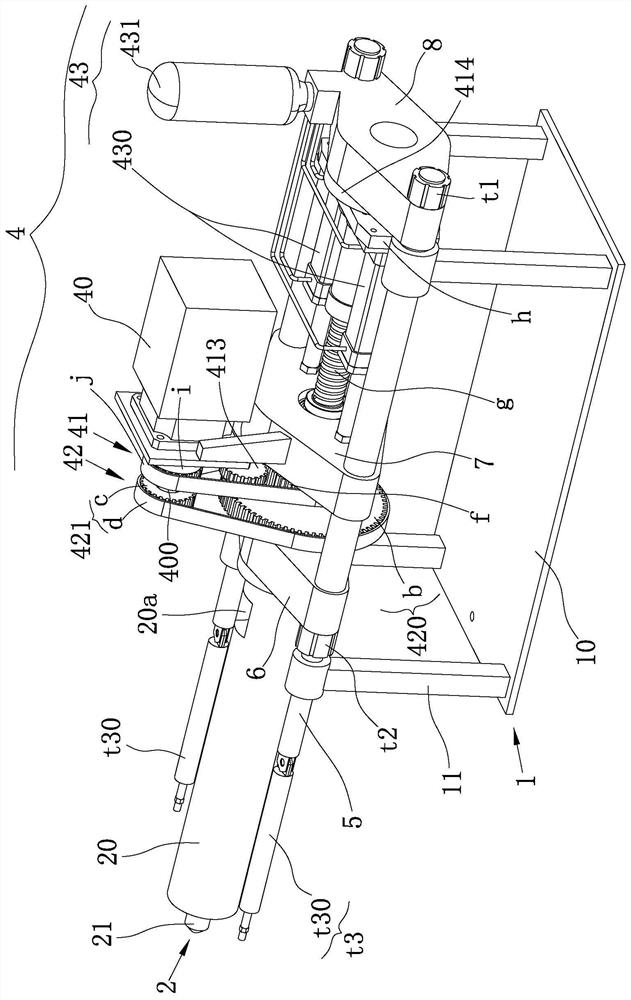

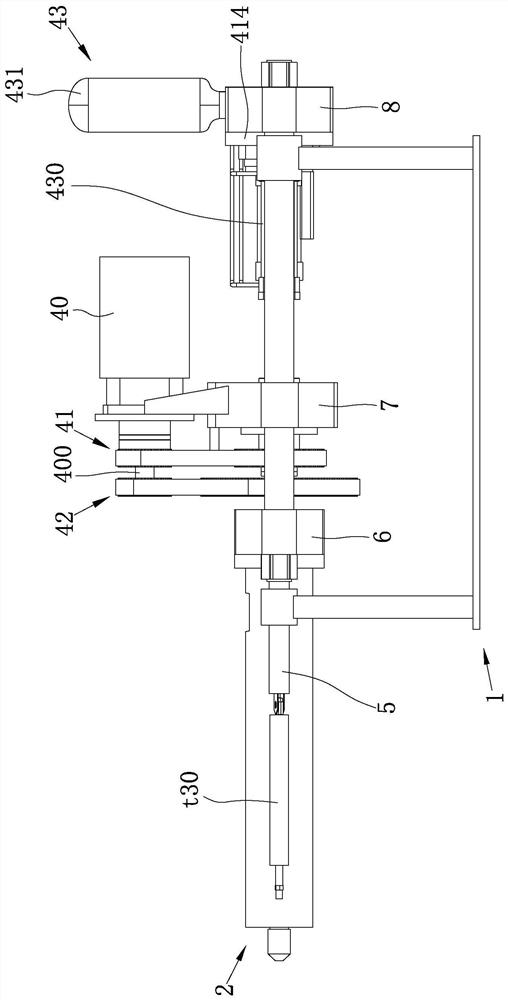

[0078] Such as figure 1 As shown, the oil-electric hybrid three-platen injection molding machine in this embodiment includes a machine base 1 , a barrel 2 , a screw 3 , and a power system 4 .

[0079] Specifically, the base 1 includes an injection platform 10 and a pillar 11 located on the injection platform 10, wherein the injection platform 10 is square, and there are four pillars 11, which are correspondingly distributed at the four corners of the injection platform 10. The power system 4 passes along the screw 3 Two injection tie rods 5 extending in the longitudinal direction are erected on the pillar 11.

[0080] In this example, the two injection rods 5 correspond to pass through the two pillars 11 on the same side.

[0081] The barrel 2 includes a barrel body 20 with a cavity formed therein, and a nozzle 21 arranged at the front end of the barrel body 20, wherein the barrel body 20 is provided with a plastic raw material inlet 2a.

[0082] The screw 3 extends along th...

Embodiment 2

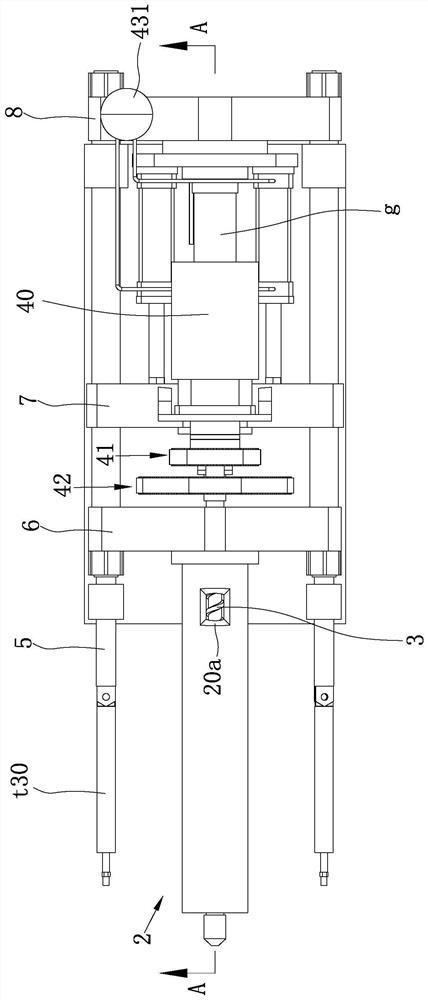

[0115] combine Figure 5 As shown, the basic structure and implementation principle of the hybrid two-platen injection molding machine in this embodiment are the same as those in Embodiment 1, except that in this example there are only the injection head plate 6 and the injection tail plate 8, and the power system There are also differences in the implementation of 4.

[0116] combine Image 6 As shown, the cylinder body 20 is fixed to the injection head plate 6 from the rear end, the injection tail plate 8 is slidably arranged on the machine base 1 as the screw 6 moves along its own length direction, and the power motor 40 and the feeding unit 42 are arranged on the injection On the tail plate 8 , the injection unit 41 and the auxiliary cylinder 430 are arranged on the injection head plate 6 and the injection tail plate 8 . With the setting of two boards, the installation of the power system is realized, the structure is compact, the volume is small, and it is easy to imple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com