Paper feeding mechanism with paper recognition function and working method thereof

A paper and paper feeding technology, applied in the direction of object supply, decorative arts, and turning objects, etc., can solve the problems of manual paper turning, which affects the efficiency of die-cutting work, and increases production costs, and achieves high production efficiency and coordinated action. Coherent, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

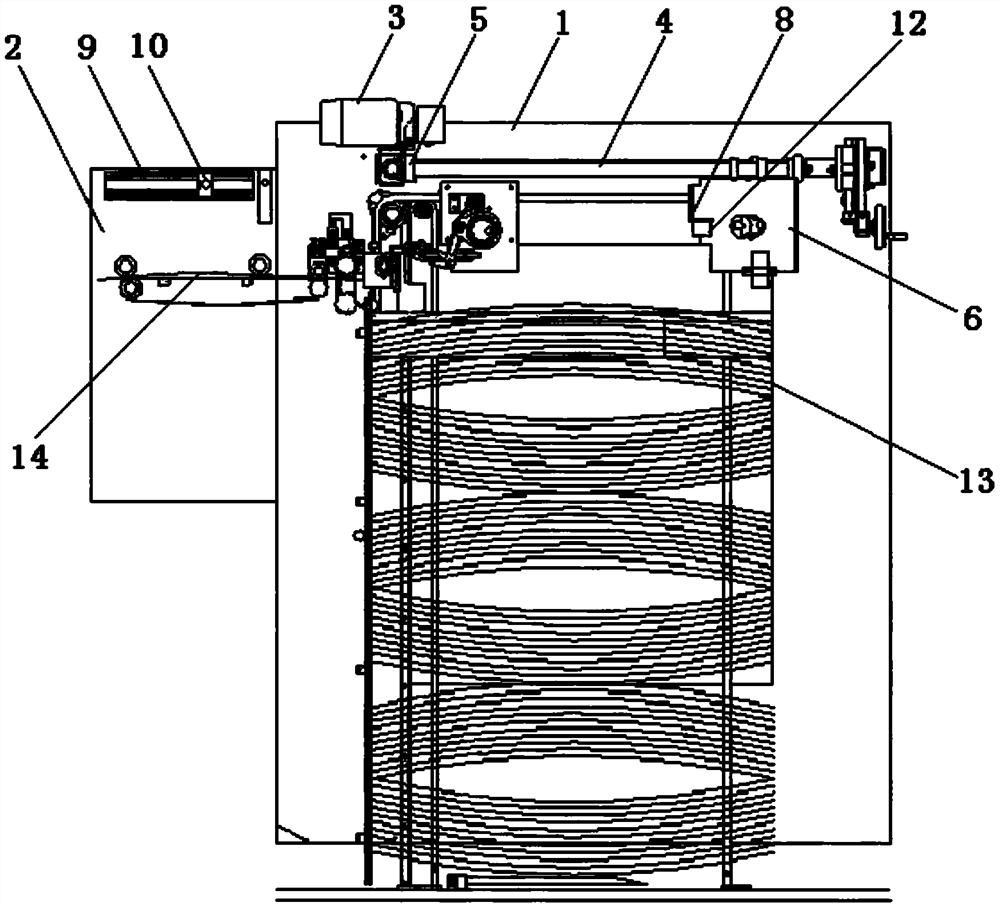

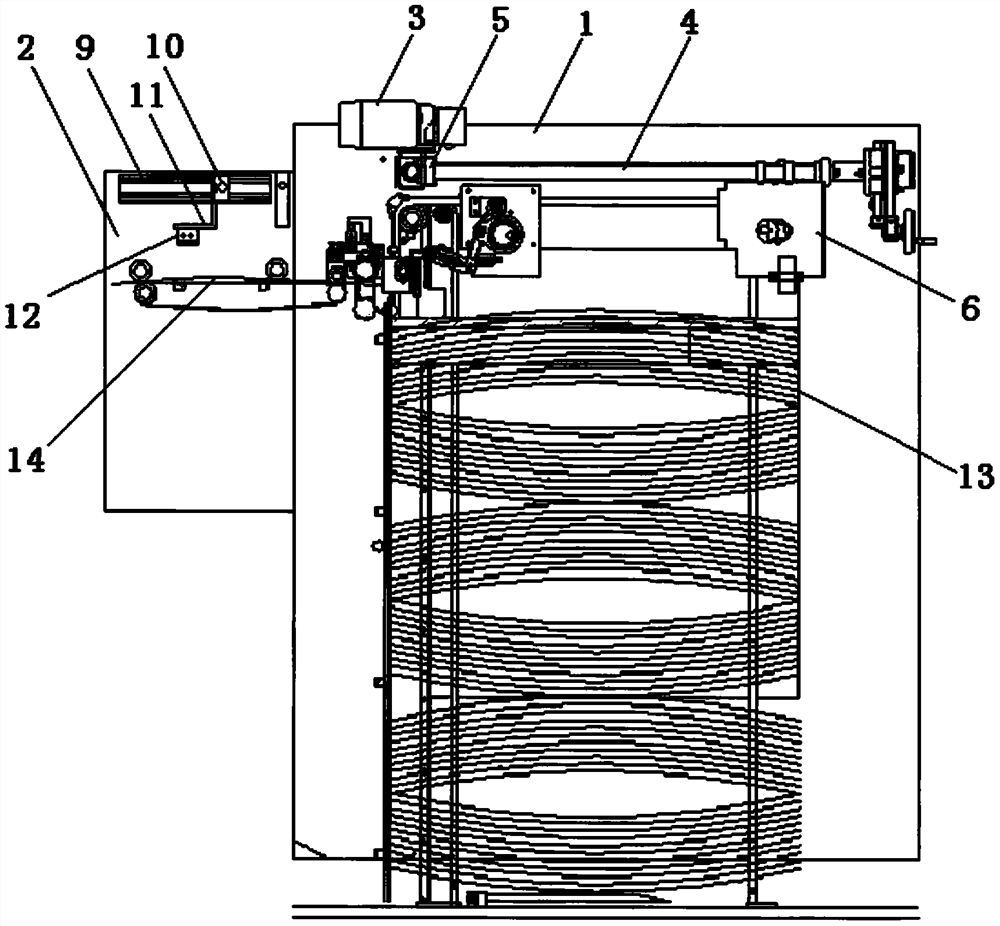

[0023] Embodiment 1: a kind of working method of the paper feeding mechanism that paper recognition function is arranged, as figure 1 , 2 shown, including the following steps:

[0024] a. When the identification system 12 is installed in the paper feeding section 1, according to the size of the paper on the paper stack 13, the front and rear positions of the identification system 12 are adjusted by adjusting the power 3 and the linear moving device 7 to ensure the optimal performance of the identification system 12. identify the location;

[0025] When the b machine starts to work, the identification system 12 will quickly detect the different states of the front and back sides of the paper on the paper pile 13. If it is the front side of the paper that does not need to be turned over, the control system will send a non-turnover to the subsequent paper turning mechanism. order, so that the paper directly passes through the turning mechanism and enters the die-cutting section...

Embodiment 2

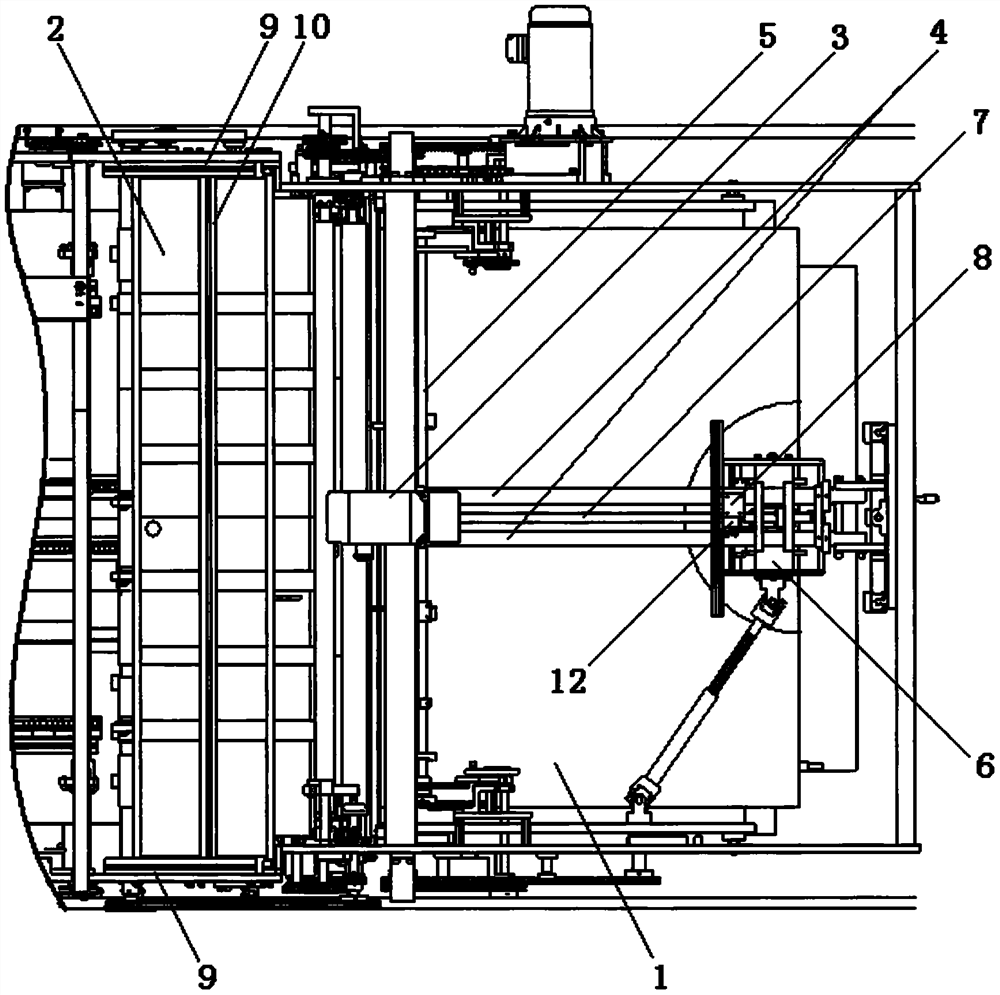

[0026] Embodiment 2: a kind of working method of the paper feeding mechanism that paper recognition function is arranged, as image 3 , 4 shown, including the following steps:

[0027] a. When the identification system 12 is installed in the paper feeding section 2, according to the size of the paper 14 arriving at the paper feeding section, the front and rear, left and right positions of the identification system 12 are adjusted by moving the crossbeam 10 left and right and the crossbeam 9 moving back and forth, so as to ensure The optimal identification position of the identification system 12;

[0028] b. When the machine starts to work, the identification system 12 will quickly detect the different states of the front and back sides of the paper 14 arriving at the paper feeding section. Instructions for overturning, so that the paper directly passes through the overturning mechanism and enters the die-cutting section; if it is the reverse side of the paper that needs to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com